Ceramic plate for curtain wall decoration and preparation method thereof

A ceramic plate and curtain wall technology, applied in the field of building decoration materials, can solve the problems of difficulty in adapting to the production and requirements of ceramic plates, high requirements for extrusion molding equipment, long drying time, etc., achieve small deformation, overcome defects and easy deformation, and be easy to dry Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

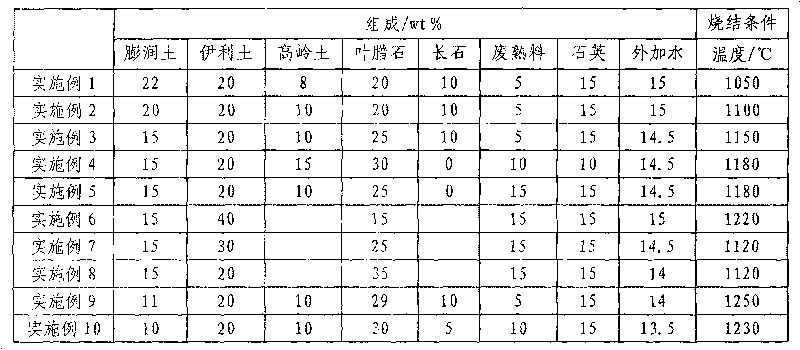

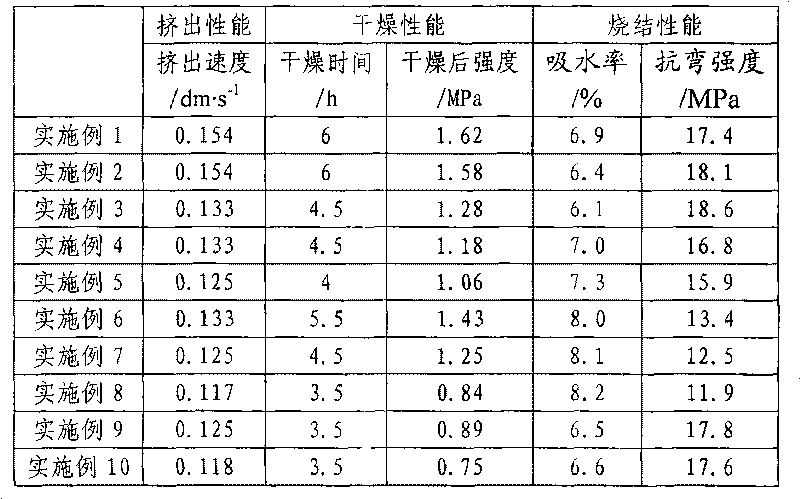

[0015] The present invention will be further described in detail below in conjunction with specific examples.

[0016] The raw material composition of pottery plate is as shown in table 1, and in the embodiment 1-10 shown in table 1, plastic material powder content is generally at 35-55% (weight), if less than 30%, plastic material content is also little in the sintered body , the reinforcing effect of coarse aggregate is limited, and the mechanical properties of the fired body decrease. If it is greater than 55wt%, the amount of bentonite added will increase correspondingly, and the plasticity of the corresponding mud is too good. Although it is beneficial to extrusion, it is difficult to dry.

[0017] The best content of bentonite is 10-22%. If it is less than 10%, the corresponding mud material may not have good plasticity, which is not conducive to extrusion. If it exceeds 25%, the plasticity of the mud is too high, it is very difficult to dry, and cracking may occur eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com