Method for prolonging life span of mixing and interconnecting indium welding spot of infrared focal plane array device

An infrared focal plane and solder joint technology, which is applied in the field of photodetection device manufacturing process, can solve the problems of extremely high wettability requirements for metallized electrodes and hybrid interconnection indium solder joints, poor performance of infrared focal plane detectors, and difficult processes. , to achieve the effect of realizing electrical connection life, not affecting the detection performance of the device, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

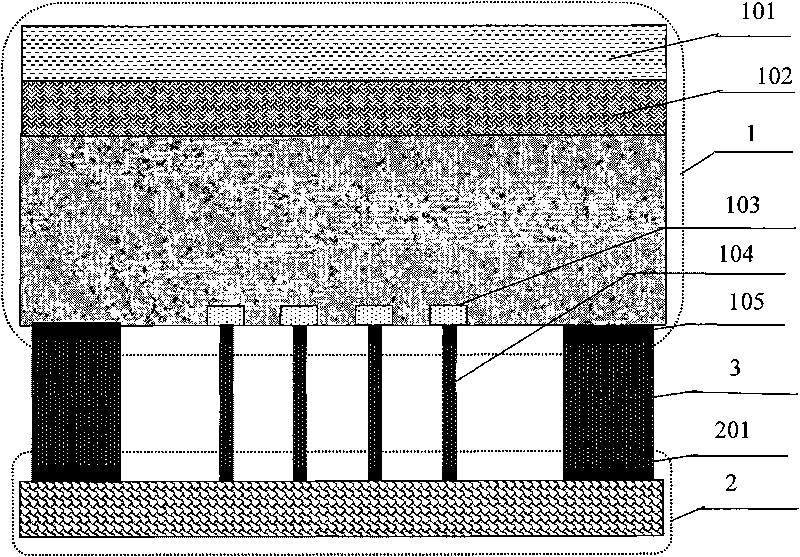

[0019] Below in conjunction with the accompanying drawings, the specific implementation of the present invention will be further described in detail by taking an infrared focal plane detector with a size of 320×240 as an example:

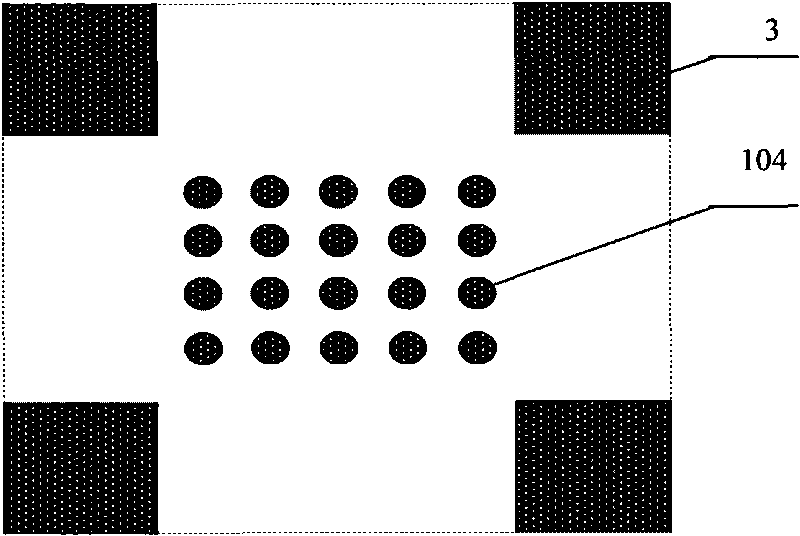

[0020] A. Using the method of double ion beam coating, the bases 105 and 201 for growing the indium-stacked bridge piers 3 are respectively prepared at the four corners of the infrared focal plane photosensitive array chip 1 and the readout circuit 2, and the base size is 640000 μm 2 , the base material is a chromium / gold composite layer (Cr / Au) that is wettable with the indium pile pier 3, the thickness of chromium is 50nm, and the thickness of gold is 200nm;

[0021] B. Using traditional photolithography technology, on the surface of the infrared focal plane photosensitive array chip 1 and the readout circuit 2, a photoresist mask for growing the hybrid interconnected indium pad array 104 and the indium-stacked bridge pier 3 is fabricated Pattern,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com