Device and method for preparing chromatographic column made of magnetic filling material

A technology of magnetic packing and preparation device, applied in the field of chromatographic columns, can solve the problems of difficult packing, high back pressure, serious particle aggregation, etc., and achieve the effects of easy configuration and operation, uniform stationary phase, and high chromatographic column efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

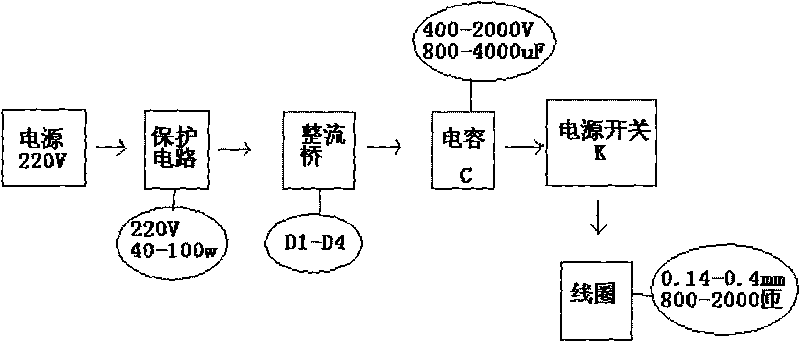

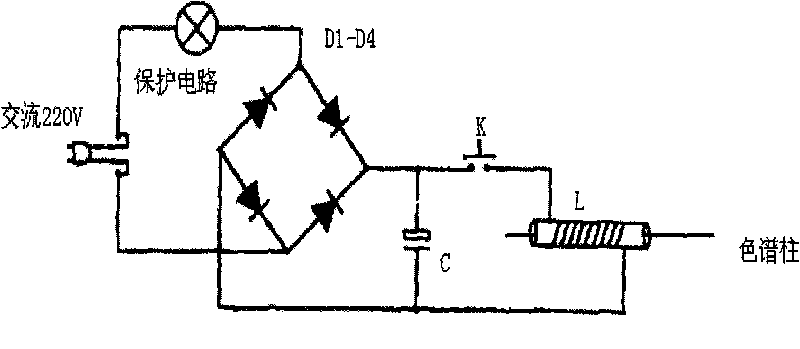

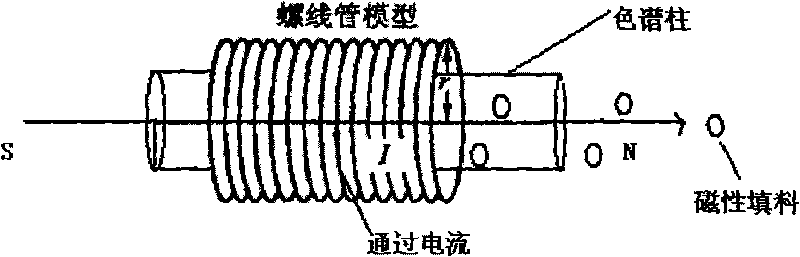

[0041] 300mg SBF-Fe 3o 4 -SiO 2 -NH 2 For the core-shell magnetic material, add 1mL of methanol, sonicate for 10min, and put it into the capillary column by the method of electrofilling. Put the pre-filled chromatographic column into the enamelled copper electromagnetic coil (1000 turns) → connect to 220V AC, the AC is boosted by the rectifier bridge to become 450V DC to charge the capacitor → capacitor C (select 450V, 990uF) is fully charged, Cut off the 220V power supply → close the power switch K → discharge the capacitor C (select 450V, 990uF) → the current passes through the enamelled copper coil (radius 0.15mm, number of turns 1000 turns) to generate a strong magnetic field in the chromatographic column → pre-filled in the chromatographic column The magnetic or core-shell magnetic filler is accelerated by a strong external magnetic field, and is ejected from one end of the chromatographic column to the other end. ①Repeat the above process of charging and discharging ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com