Preparation method of germane

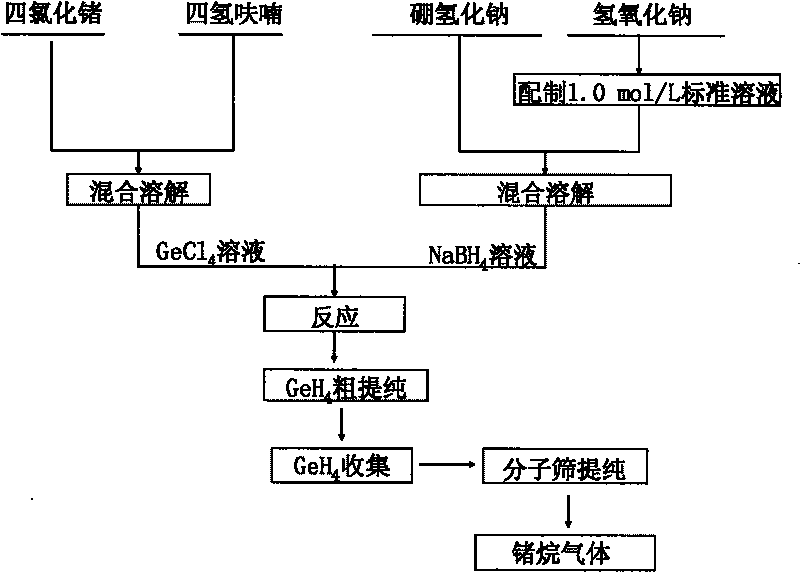

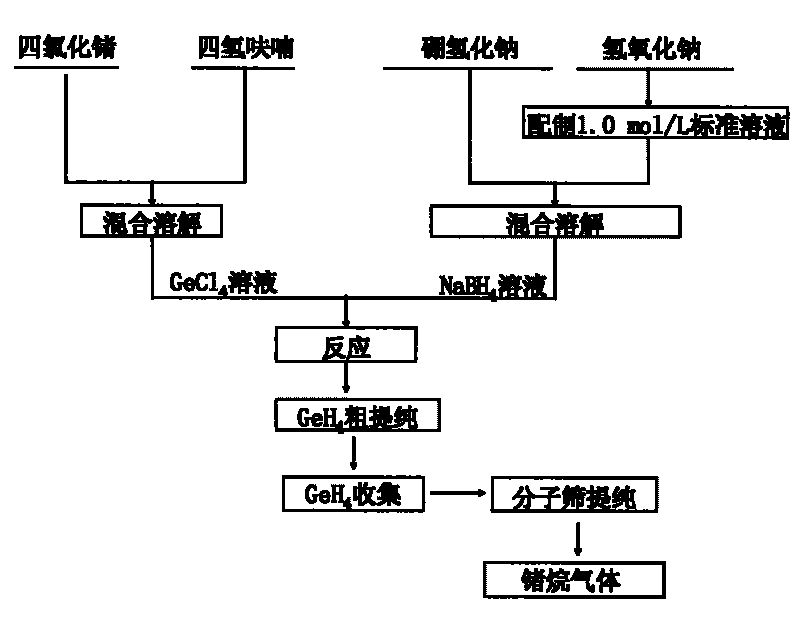

A technology of germane and germanium tetrachloride, which is applied in the field of special gas preparation, can solve the problems of difficult separation and purification, large consumption of raw materials, long process route, etc., and achieve the effect of easy separation and purification, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh 34.1g (0.9mol) of sodium borohydride, add it to 1mol / L sodium hydroxide solution, stir to dissolve, and transfer it to a reaction vessel; dissolve 104.7mL (0.9mol) of germanium tetrachloride in 104.7mL of tetrahydrofuran , transferred to the dropping funnel. Install the dropping funnel into the germane generation system and check the airtightness of the unit. Use a vacuum pump to evacuate the system. After the vacuum degree drops below 10Pa, control the dropping funnel to add liquid dropwise to the reactor at a rate of 7mL / min, and react under magnetic stirring. The reaction time is 3h. The generated germane gas is passed into 10mol / L sodium hydroxide solution and calcium chloride drying tube respectively, and is collected by a gas collector after rough purification to remove impurity air and moisture. The germane gas in the above collector is adsorbed and purified through 4A molecular sieve and 5A molecular sieve respectively.

Embodiment 2

[0022] Take by weighing 30.3g (0.8mol) sodium borohydride, join in the sodium hydroxide solution of 1mol / L, stir to dissolve, transfer in the reaction vessel; Take 23.3mL (0.2mol) germanium tetrachloride and dissolve in 70mL tetrahydrofuran, Transfer to a dropping funnel. Install the dropping funnel into the germane generation system and check the airtightness of the unit. Use a vacuum pump to evacuate the system. After the vacuum degree drops below 10Pa, control the dropping funnel to add liquid dropwise to the reactor at a rate of 3mL / min, and react under magnetic stirring. The reaction time is 0.5h. The generated germane gas is passed into 5mol / L sodium hydroxide solution and calcium chloride drying tube respectively, and is collected by a gas collector after rough purification to remove impurity air and moisture. The germane gas in the above collector is adsorbed and purified through 4A molecular sieve and 5A molecular sieve respectively.

Embodiment 3

[0024] Take by weighing 151.3g (4.0mol) sodium borohydride, join in the sodium hydroxide solution of 1mol / L, stir to dissolve, transfer in the reaction vessel; Get 46.5mL (0.4mol) germanium tetrachloride is dissolved in 280mL tetrahydrofuran, Transfer to a dropping funnel. Install the dropping funnel into the germane generation system and check the airtightness of the unit. Use a vacuum pump to evacuate the system. After the vacuum degree drops below 10Pa, control the dropping funnel to add liquid dropwise to the reactor at a rate of 30mL / min, and react under magnetic stirring. The reaction time is 1.5h. The generated germane gas is passed into 1mol / L potassium hydroxide solution and calcium chloride drying tube respectively, and is collected by a gas collector after rough purification to remove impurity air and moisture. The germane gas in the above collector is adsorbed and purified through 4A molecular sieve and 5A molecular sieve respectively.

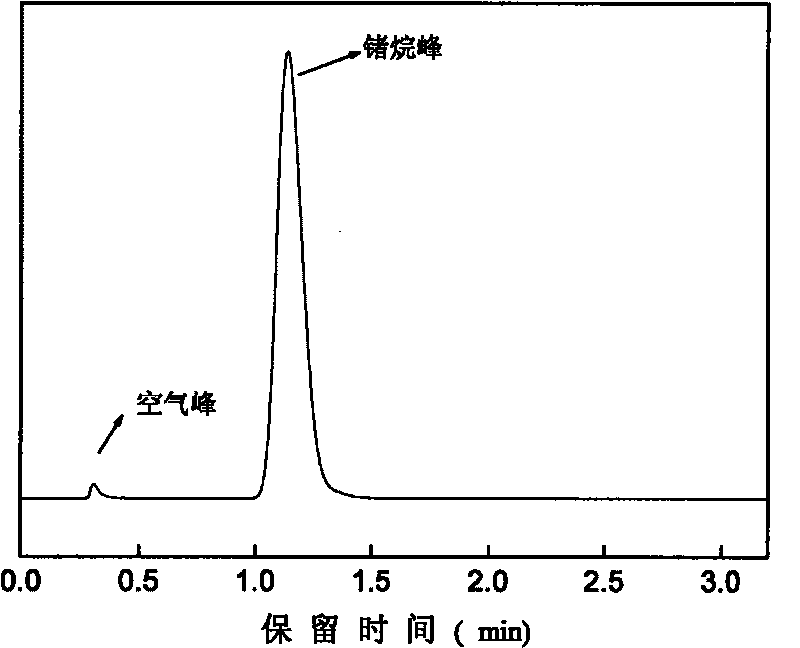

[0025] figure 2 It is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com