High-permeability prime coating emulsified asphalt and preparation method thereof

An emulsified asphalt and permeability technology is applied in the field of emulsified asphalt with strong permeability and its preparation. Inexpensive, viscosity-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

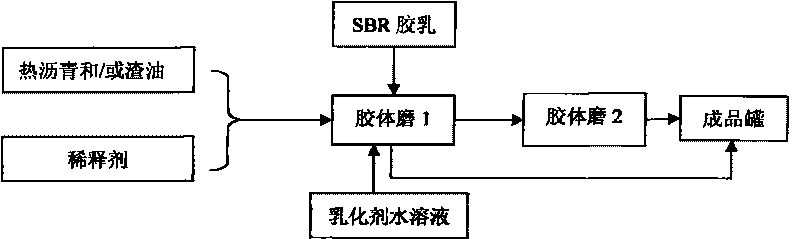

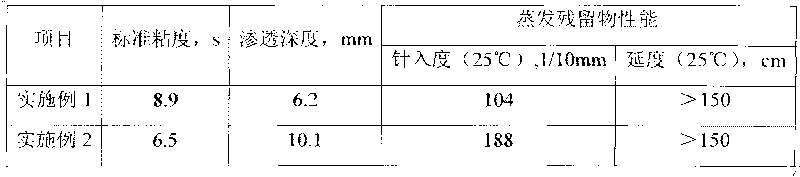

[0025] Tahe light residue oil 200g, lubricating oil furfural refined extract oil and FCC oil slurry mixed at 1:1 for a total of 15g, emulsifier JYR3 and octadecylamine were mixed at a ratio of 10:2 for a total of 6g, CaCl 2 0.5g of water was added to 260g, and cationic SBR latex was 25g. The above substances are figure 1 The shown 100% is emulsified by a colloid mill 1 with a grinding gap of 10 μm, 70% of the obtained product is directly injected into the finished product tank, and the remaining 30% is further emulsified through a colloid mill 2 with a grinding gap of 5 μm, and then injected into the finished product tank and mixed with the previous product. Get the finished product. The obtained finished product complies with the requirements of JTG F40-2004 for cationic emulsified asphalt for permeable layers, and the main properties are shown in Table 2.

Embodiment 2

[0027] Maoming 70# bitumen 200g, 40g mixed with fatty acid leftovers at 1:1, emulsifier JYR5 and 1631 mixed at 10:1, total 8.25g, NH 4 1.0 g of Cl was added with water to make 235 g, and the cationic SBR latex was 25 g. The above substances are figure 1 The shown 100% is emulsified by a colloid mill 1 with a grinding gap of 10 μm, 80% of the obtained product is directly injected into the finished product tank, and the remaining 20% is further emulsified through a colloid mill 2 with a grinding gap of 5 μm, and then injected into the finished product tank and mixed with the previous product. Get the finished product. The obtained finished product complies with the requirements of JTG F40-2004 for cationic emulsified asphalt for permeable layers, and the main properties are shown in Table 2.

[0028] Table 1 Technical index of cationic cationic SBR latex for modified asphalt

[0029] project name

Technical indicators

Exterior

milky

Solid conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com