Method for separating mixed methyl cyclohexane diacid

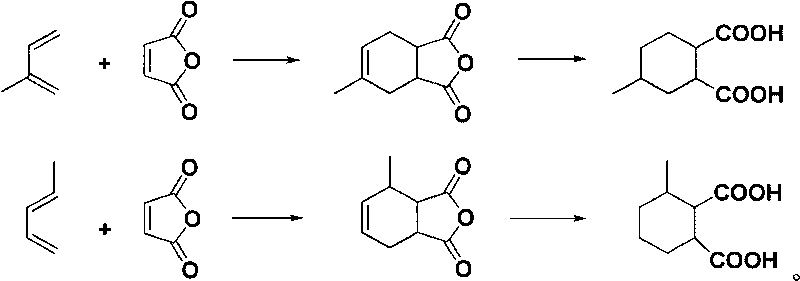

A technology of methylcycloadipic acid and cycloadipic acid, which is applied in the separation/purification of carboxylic acid compounds, organic chemistry and other directions, can solve the problems of difficult separation, high cost, difficult separation, etc., and achieves good repeatability and recovery. High rate, good for industrial amplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The mixture comes from a chemical plant in Shangyu, and the contents of the two acids are 50wt% (3-methyl-1,2-cyclohexanedioic acid) and 48wt% (4-methyl-1,2-cyclohexanedioic acid) respectively. adipic acid).

[0037] In a 250ml round bottom flask equipped with a condensing reflux tube, add 9.6g (0.1mol) of 3-aminopyridine, 38g of the mixture and 200ml of methanol, heat to reflux for 0.5h while stirring, and cool to room temperature. After standing for 2 days, the white crystal crude product was obtained, filtered, and the filtrate A was retained, the filter cake A was recrystallized with enough methanol to dissolve the filter cake A, filtered, washed 3 times with methanol (3×50ml), and naturally dried in the air to obtain a white compound crystals.

[0038] Dissolve the above white complex crystals in 50ml of 1N hydrochloric acid, adjust the pH value to 7.0, let it stand for precipitation, and filter to obtain filter cake B and filtrate B. Filter cake B was washed wit...

Embodiment 2

[0042] The mixture comes from a chemical plant in Shangyu, and the contents of the two acids were tested to be 65wt% (3-methyl-1,2-cyclohexanedioic acid), 32wt% (4-methyl-1,2-cyclohexanedioic acid) adipic acid)

[0043]In a 500ml round bottom flask equipped with a condensing reflux tube, add 18.8g of 3-picoline, 60g of the mixture and 400ml of methanol respectively, heat to reflux for 0.3h while stirring, and cool to room temperature. After standing for 2 days, the white crystal crude product was obtained, filtered, the filtrate A was retained, the filter cake A was recrystallized with enough ethanol to dissolve the filter cake A, filtered, washed with ethanol 3 times (3×50ml), and naturally dried in the air to obtain a white complex crystals.

[0044] Dissolve the above white complex crystals in 90ml of 1N hydrochloric acid, adjust the pH value to 7.0, let it stand for precipitation, and filter to obtain filter cake B and filtrate B. Filter cake B was washed with 20 ml of s...

Embodiment 3

[0048] The mixture comes from a chemical plant in Shangyu, and the contents of the two acids are 55wt% (3-methyl-1,2-cyclohexanedioic acid) and 43wt% (4-methyl-1,2-cyclohexanedioic acid) respectively. adipic acid)

[0049] In a 2000ml round bottom flask equipped with a condensing reflux tube, add 80g of pyridine, 180g of the mixture and 1500ml of water, heat to reflux for 0.3h under stirring, and cool to room temperature. After standing for 2 days, the white crystal crude product was obtained, filtered, the filtrate A was retained, the filter cake A was recrystallized with enough water to dissolve the filter cake A, filtered, washed with water 3 times (3×50ml), and naturally dried in the air to obtain a white complex crystal .

[0050] Dissolve the above-mentioned white complex crystal in 130ml of 1N hydrochloric acid, adjust the pH value to 7.0, let it stand for precipitation, and filter to obtain filter cake B and filtrate B. Filter cake B was washed with 40 ml of saturate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com