Wood adhesive prepared by degrading soybean protein by utilizing strong basicity and preparation method thereof

The technology of wood adhesive and soybean protein is applied in the field of wood processing adhesive and its preparation, which can solve the problems of high moisture content, low soybean protein content, high viscosity, etc., and achieves increased adsorption and improved bonding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

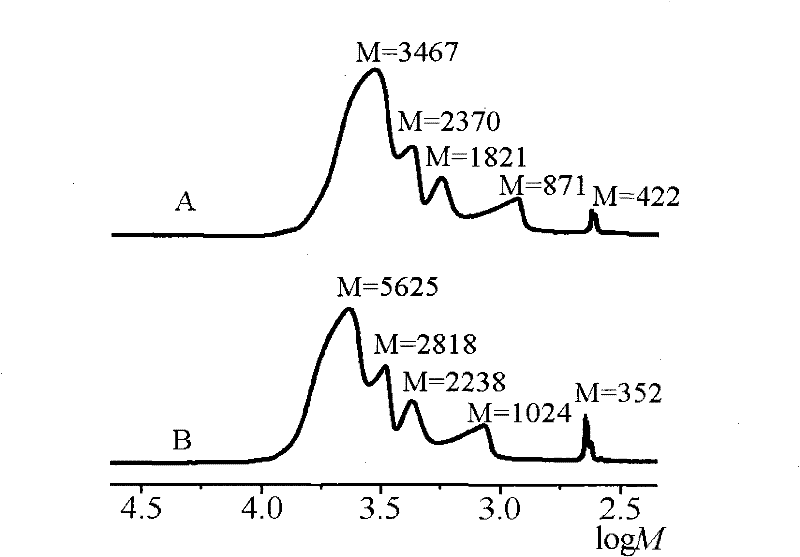

Image

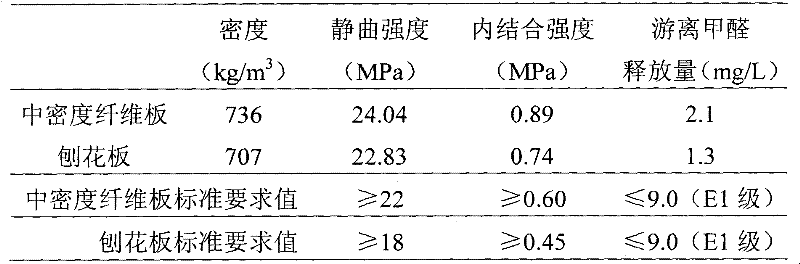

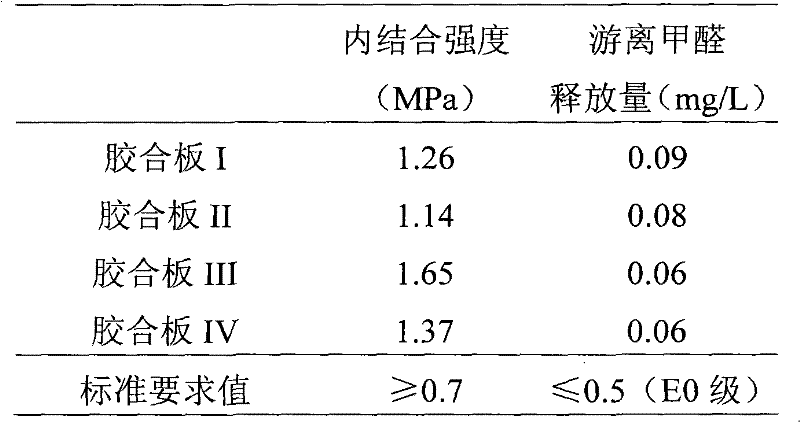

Examples

specific Embodiment approach 1

[0015] Specific Embodiment 1: The wood adhesive prepared by degrading soybean protein with strong alkali in this embodiment is degraded by 60-80 parts of defatted soybean protein powder, 5-10 parts of strong alkali and 95 parts of water in parts by weight. After the reaction, use concentrated phosphoric acid to adjust the pH value to 6.5-7.5, and then add 0.01-20 parts of binary aldehyde and mix well.

[0016] The wood adhesive of this embodiment has a high solid content (the solid content of the glue measured according to the method described in the national standard GBT 14074-2006 is 40.3% to 50.6%), high soybean protein content (its soybean protein powder or soybean protein isolate The weight fraction of the glue is 32% to 42%), low viscosity (measured at 25°C according to the method described in the national standard GBT 14074-2006, the viscosity of the glue is 33 to 245mPa·s), good bonding effect and extremely low free It is characterized by formaldehyde release and is an...

specific Embodiment approach 2

[0017] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the wood adhesive prepared by degrading soybean protein with strong alkali is composed of 60-80 parts by weight of soybean protein isolate, 5-10 parts of strong Alkali and 95 parts of water undergo a degradation reaction, then use concentrated phosphoric acid to adjust the pH value to 6.5-7.5, and then add 0.01-20 parts of binary aldehyde and mix well.

specific Embodiment approach 3

[0018] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the strong base is sodium hydroxide or potassium hydroxide. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com