Method for extracting papaya seed oil by using supercritical CO2

A papaya seed, supercritical technology, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems that have not been reported, and achieve the effect of no solvent residue, good product quality and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

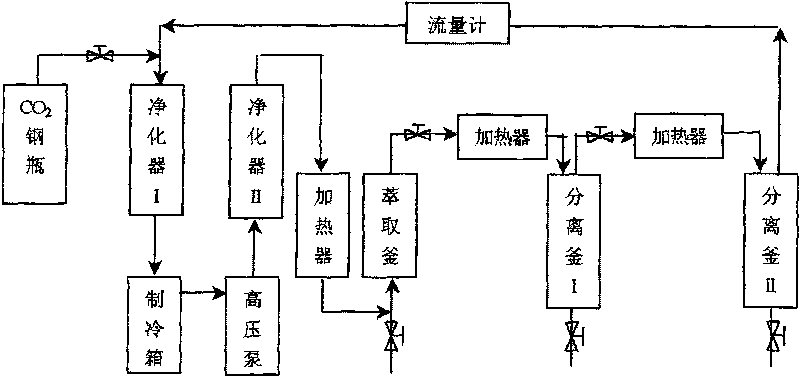

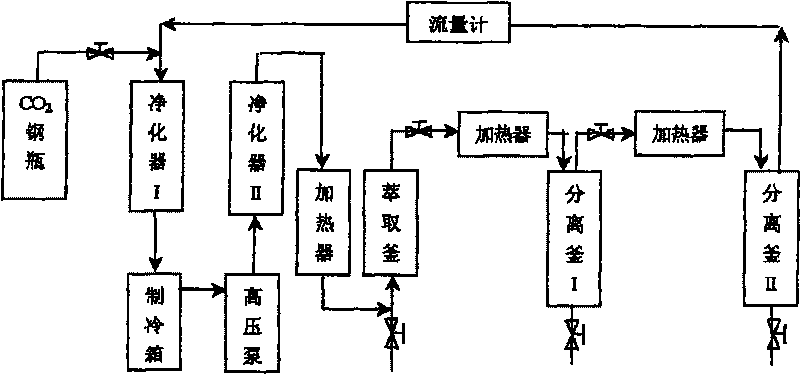

Image

Examples

Embodiment 1

[0015] (1) Wash and dry 1kg of papaya seeds, pulverize them to 40 mesh and place them in the barrel of a 1L extraction kettle;

[0016] (2) Turn on the refrigeration and cold cycle, set the temperature of the cold box to 0°C; set the temperature of the extraction kettle to 50°C, the temperature of the separation kettle I to 45°C, and the temperature of the separation kettle II to 55°C, and then turn on the CO 2 Cylinder, CO 2 Enter the cold box for liquefaction through the gas purifier I, and then start the high-pressure pump to convert the CO 2 It is pumped into the extraction kettle through the purifier II and the heater, and the pressure is increased to 25MPa to make it a supercritical fluid. In the extraction kettle, it is fully mixed with papaya seeds, so that the papaya seed oil dissolves to CO 2 Medium; (3) CO dissolved in papaya seed oil 2 It flows out from the top of the extraction kettle and enters the depressurization system. In order to realize the complete separ...

Embodiment 2

[0018] (1) Wash and dry 1kg of papaya seeds, pulverize them to 30 mesh and place them in the barrel of a 1L extraction kettle;

[0019] (2) Turn on the refrigeration and cold cycle, set the temperature of the cold box to 0°C; set the temperature of the extraction kettle to 40°C, set the temperature of the separation kettle I to 50°C, and set the temperature of the separation kettle II to 50°C, then turn on the CO 2 Cylinder, CO 2 Enter the cold box for liquefaction through the gas purifier I, and then start the high-pressure pump to convert the CO 2 It is pumped into the extraction kettle through the purifier II and the heater, and the pressure is increased to 20MPa to make it a supercritical fluid. In the extraction kettle, it is fully mixed with papaya seeds to make the papaya seed oil dissolve to CO 2 Medium; (3) CO dissolved in papaya seed oil 2 It flows out from the top of the extraction kettle and enters the depressurization system. In order to realize the complete sep...

Embodiment 3

[0021] (1) Wash and dry 1kg of papaya seeds, crush them to 50 mesh and place them in the barrel of a 1L extraction kettle;

[0022] (2) Turn on the refrigeration and cold cycle, set the temperature of the cold box to 0°C; set the temperature of the extraction kettle to 45°C, the temperature of the separation kettle I to 40°C, and the temperature of the separation kettle II to 40°C, and then turn on the CO 2 Cylinder, CO 2 Enter the cold box for liquefaction through the gas purifier I, and then start the high-pressure pump to convert the CO 2 It is pumped into the extraction kettle through the purifier II and the heater, and the pressure is increased to 35MPa to make it a supercritical fluid. In the extraction kettle, it is fully mixed with the papaya seeds to dissolve the papaya seed oil to CO 2 Medium; (3) CO dissolved in papaya seed oil 2 It flows out from the top of the extraction kettle and enters the depressurization system. In order to realize the complete separation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com