Application of carbon complementary device for cultivating microalgae in a large-scale way

A technology for large-scale cultivation and carbon supplementation, which can be used in microorganism-based methods, enzymology/microbiology devices, biochemical cleaning devices, etc., and can solve the problems of large power consumption and complex equipment for oxygen analysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Spirulina was cultured in a closed-type photobioreactor. The algal species were from the Institute of Process Engineering, Chinese Academy of Sciences, the species was Spirulina Platensis, the medium was Zarrouk medium, and the initial concentration of sodium bicarbonate in the culture medium was 0.1mol / L.

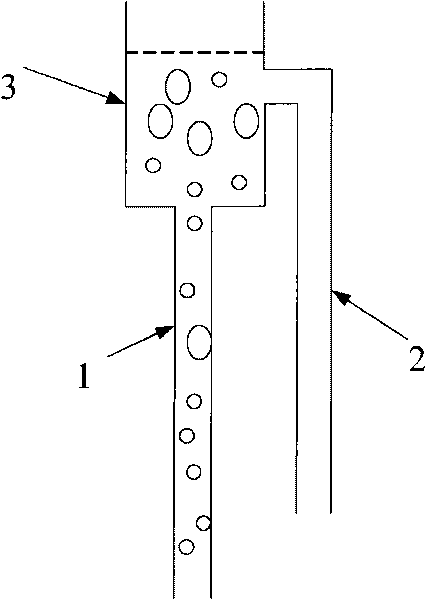

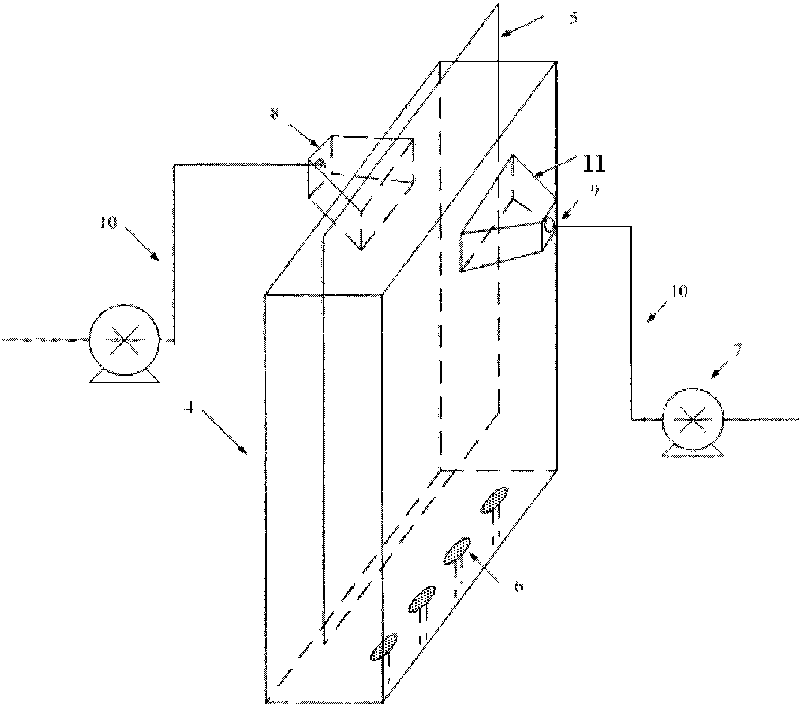

[0054] See figure 2 and image 3 . In high 100cm, wide 80cm, thickness is 20cm, and material is the well-type container 4 of plexiglass plate that is 2cm thick and is not lower than the liquid level in the container, and the vertical dividing plate 5 that has 20 centimeters gaps with the bottom of the container, The partition is a plastic plate with a thickness of 1.0 cm, located in the middle of the thickness direction of the well-type container, and the width matches the well-type container; 8 glass sand core gas distributors 6 of model G2 are installed at the bottom of the well-type container, and the gas The distributor is located directly below the bulkhead...

Embodiment 2

[0061] Spirulina was cultured in a closed-type photobioreactor. The algal species were from the Institute of Process Engineering, Chinese Academy of Sciences, the species was Spirulina Platensis, the medium was Zarrouk medium, and the initial concentration of sodium bicarbonate in the culture medium was 0.1mol / L.

[0062] See figure 2 and Figure 4 . In high 100cm, wide 40cm, thickness is 20cm, and material is the well-type container 4 of 2cm thick plexiglass plate and is equipped with not lower than the liquid level in the container, and the vertical dividing plate 5 that has 20 centimeters gaps with the bottom of the container, The partition is a plastic plate with a thickness of 1.0 cm, located in the middle of the thickness direction of the well-type container, and the width matches the well-type container; four glass sand core gas distributors 6 of model G2 are installed on the bottom of the well-type container, and the gas The distributor is located on the downstream...

Embodiment 3

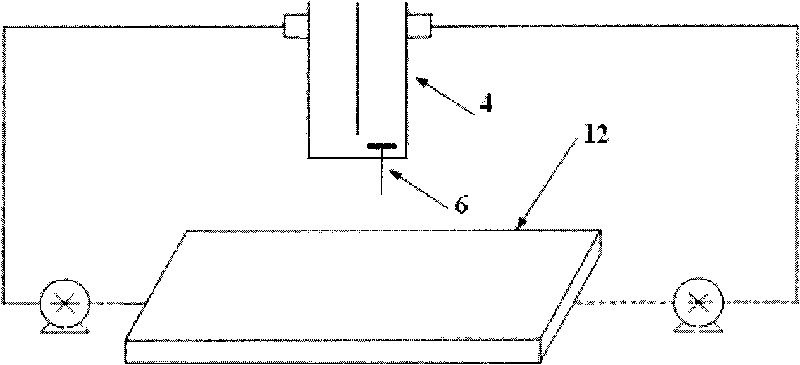

[0069] Spirulina was cultivated in a tubular photobioreactor, and the plate photobioreactor in Example 2 was changed into a tubular photobioreactor.

[0070] The cultivation system is composed of 1 group of tubular photoreactors 12 and 2 trap-type carbon replenishing devices of Example 2. The two trap-type carbon replenishment devices are connected in parallel and connected with both ends of the tubular photoreactor group to form a loop, such as Figure 4 shown.

[0071] A group of tubular photoreactors consists of 40 tubular photoreactor units connected in parallel. Specifications of the tubular photobiological reaction unit: the inner diameter of the tube is 3cm, the outer diameter is 4cm, and the length is 25m. Every 10 tubes form a group side by side, and the two ends are connected by manifolds, a total of 4 groups. Tube material is glass. Four sets of tubular photobioreactors are connected in parallel. placed horizontally.

[0072] Others are with embodiment 2.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com