Low-temperature alkaline lead-smelting method

A lead smelting and low-temperature technology, applied in the field of metallurgy, can solve problems such as air, land and water pollution, high energy consumption, smoke pollution, etc., and achieve the effect of good environment, mild conditions and pollution elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

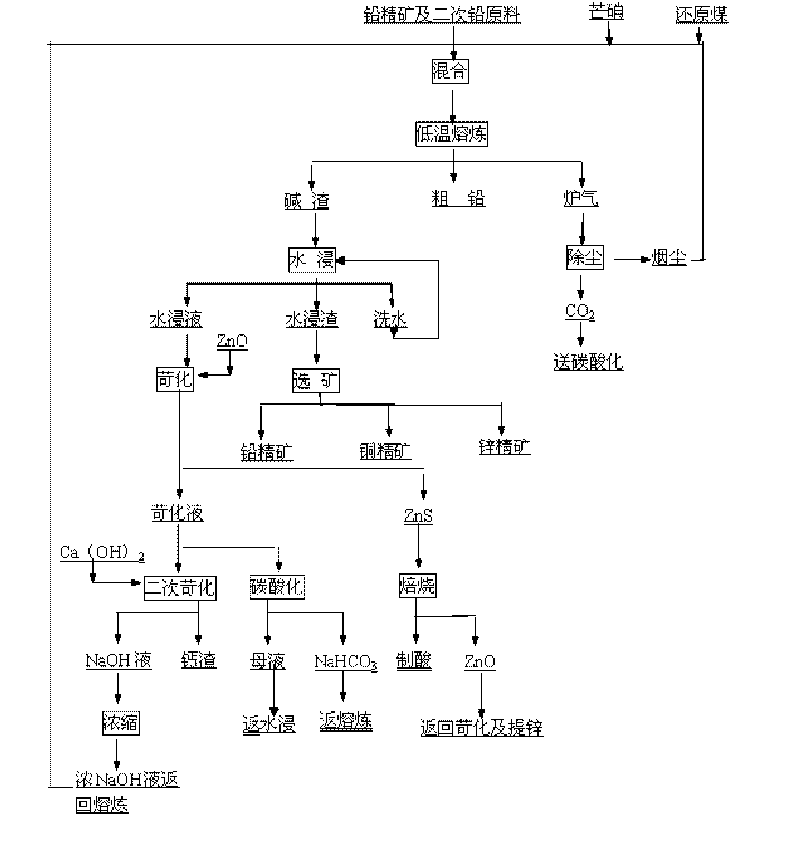

Method used

Image

Examples

Embodiment 1

[0043] Low-temperature alkaline lead smelting with 1# lead sulfide concentrate as raw material, the composition of the concentrate is (%): Pb70.12, Fe6.08, S15.04, Zn2.84, Cu0.40, SiO 2 0.79.

[0044] A. Alkaline smelting process

[0045] Weigh 21.66 grams of caustic soda and dissolve it in 30ml of water, mix with 100 grams of 1# lead concentrate and 5 grams of reduced pulverized coal, granulate, place in a graphite crucible, weigh 76.07 grams of soda ash to cover the surface of the pellets, and rise to Heat preservation and smelting at 850°C for 60 minutes; the obtained crude lead weighs 65.68g, the direct yield of lead is 92%, and the basic slag is 83.5g.

[0046] B. Water immersion process

[0047] Add 350mL of water and 82.3g of slag to a 1000ml beaker, filter at 60°C for 2 hours, wash the filter residue with 100mL of water for 3 times, and the pH value is 7.5. The dry weight of the filter residue is 31.1g, containing Pb18.04%, Zn9.13%, Cu1.29%, Fe19.55%; filtrate 500mL,...

Embodiment 2

[0057] 2# lead sulfide concentrate and lead sulfate slag are used as raw materials, and the mass ratio is 1:1. The composition of 2# lead concentrate is (%): Pb51.55, Fe5.34, S18.52, Zn11.53, SiO 2 2.69, Cu0.11; the composition (%) of lead sulfate slag is Pb65, S10.04; the mixture contains Pb58.27%, S14.28%.

[0058] A. Melting process

[0059] Weigh 34.6 grams of caustic soda and dissolve it in 30ml of water, mix it with 100 grams of mixed lead raw material and 15 grams of reduced pulverized coal, and granulate it, place it in a graphite crucible, then weigh 75.70 grams of soda ash, cover the surface of the granulated material, and raise to 850°C Heat preservation and smelting for 60 minutes; the obtained crude lead weighs 54.11g, the direct yield of lead is 92.8%, and the basic slag is 131.04g.

[0060] B. Water immersion process

[0061] Add 350mL of water into a 1000ml beaker, soak 125g of the above-mentioned slag in it, loosen it, raise the temperature to 90°C, stir an...

Embodiment 3

[0071] Still use 1# lead sulfide concentrate as raw material for low temperature alkaline lead smelting.

[0072] A. Alkaline smelting process

[0073] Weigh 40.5 grams of caustic soda and dissolve it in 50 ml of water, then weigh 56.00 grams of soda ash and 5 grams of reduced pulverized coal, mix them with 100 grams of 1# lead concentrate, place them in a graphite crucible, heat up to 650 ° C for 90 minutes, and obtain crude lead The weight is 64.61g, the direct yield of lead is 90.5%, and the basic slag is 93.8g.

[0074] B, C, D, E, F processes are as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com