Novel unit module for solar-powered self-driven electronic paper apparatus and method for preparing same

A unit module and solar cell technology, which is applied in the manufacture of electric solid devices, capacitor parts, semiconductor/solid state devices, etc., can solve the problems of low coloring density, etc., and achieve the effects of simple preparation process, low power consumption and wide viewing angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

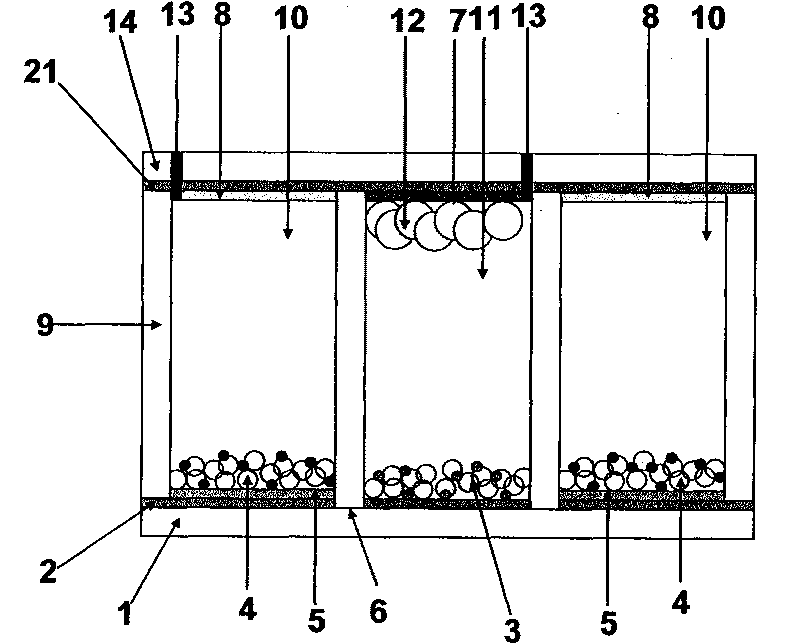

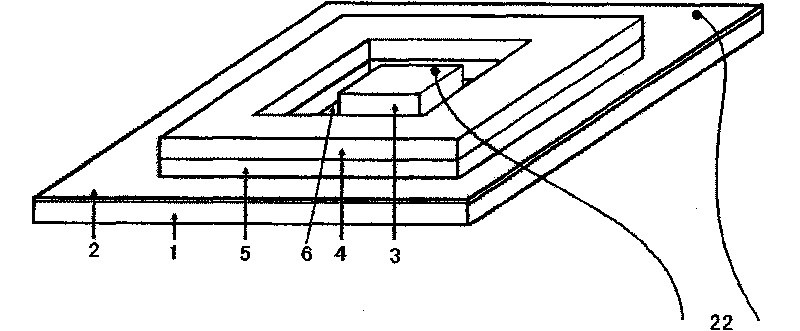

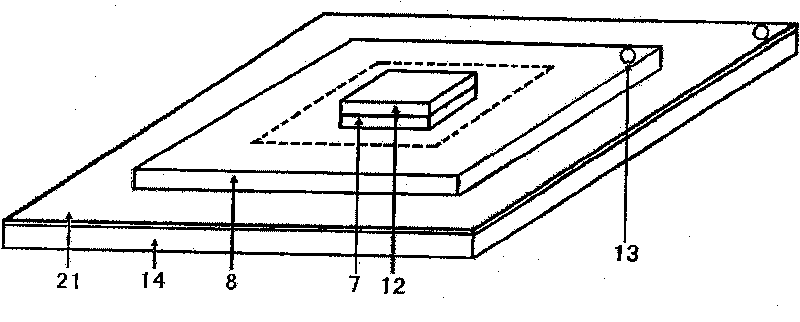

[0026] Design the display module, prepare two 4cm×5cm glass substrates, reserve packaging holes, the radius of the packaging holes is 3mm, the specific process steps are as follows:

[0027] 1. Preparation of conductive glass

[0028] 1. Preparation of cathode conductive glass:

[0029] Preparation of the lower glass substrate 1 mainly includes cutting, polishing, and cleaning of the lower glass;

[0030] The cathode electrode, i.e. the preparation of the lower conductive film 2: various film-forming means such as screen printing, evaporation, magnetron sputtering, and film-forming techniques can be used to prepare the lower conductive film 2 on the lower glass substrate 1, which can be used The material includes any of metals such as Ag, Al, Cu, Cr or Ni, or ZnO: Al, ITO, FTO, SnO 2 Any of the other conductive oxides, FTO is used in this example;

[0031] Cathode electrode patterning: use conventional chemical etching technology to etch a "mouth"-shaped groove on the lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com