Chitosan nanoparticle and preparation method and application thereof

A chitosan nanoparticle, chitosan technology, applied in the application, food preparation, pharmaceutical formulation and other directions, can solve the problems of large dose, long dissolution time, adverse reactions, etc., achieve small dose, simple and easy method, toxic Effects with few side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

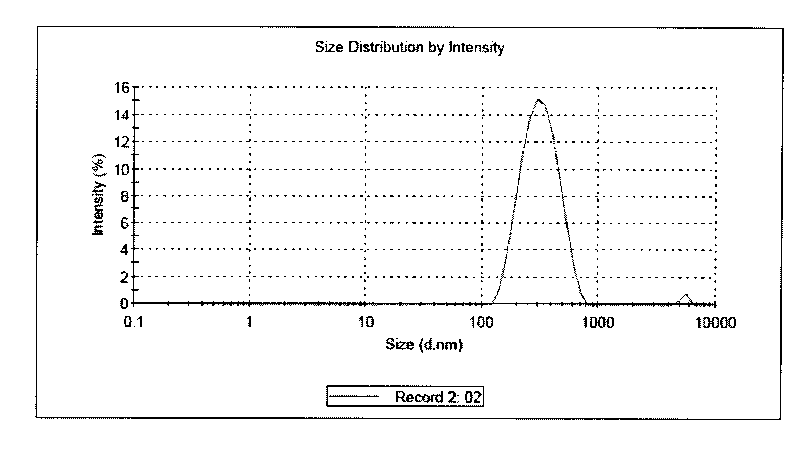

[0045] The preparation of embodiment 1 chitosan nanoparticles

[0046] (1) 25g chitosan (self-made or commercially available product according to the existing method, the reference molecular weight is 300,000 to 500,000, but the molecular weight has no direct relationship with the realization of the technology of the present invention, the same below) is dissolved in the acetic acid of 1000ml0.5% In the solution, stir to make it dissolve completely, and place it for later use;

[0047] (2) Add 100ml of 0.75mg / ml TPP to the chitosan solution in step (1) under the condition of mechanical stirring at room temperature and 800r / min, react for 45min, the system has obvious blue opalescence, and obtains nano-suspension liquid;

[0048] (3) The nanosuspension obtained in step (2) is concentrated by rotary evaporation at a temperature of 70° C., and the volume is evaporated to half of the volume of the nanosuspension;

[0049] (4) The concentrated solution obtained in step (3) is spr...

Embodiment 2

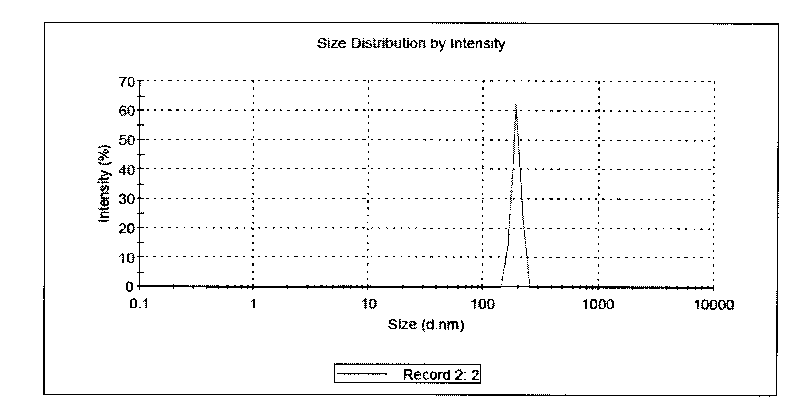

[0050] The preparation of embodiment 2 chitosan nanoparticles

[0051] (1) 25g chitosan is dissolved in the acetic acid solution that 1000ml volume ratio concentration is 1%, stirs to make it dissolve completely, place for subsequent use;

[0052](2) Add 0.85mg / ml TPP 100ml to the chitosan solution at room temperature and 600r / min mechanical stirring, and react for 60min. The system has obvious blue opalescence to generate a nanosuspension;

[0053] (3) The nanosuspension obtained in step (2) is concentrated by rotary evaporation at 60° C. under temperature control, and the volume is evaporated to half of the volume of the nanosuspension;

[0054] (4) The concentrated solution obtained in step (3) is spray-dried, the inlet temperature is set to 160°C, the outlet temperature is 85°C, the injection flow rate is 600ml / h, the pressure is 13atm, and the wind speed is 0.75m 3 / min. The resulting spray-dried chitosan nanoparticles.

Embodiment 3

[0055] The preparation of embodiment 3 chitosan nanoparticles

[0056] (1) 25g chitosan is dissolved in the acetic acid solution that 1000ml volume ratio concentration is 2%, stirs to make it dissolve completely, place for subsequent use;

[0057] (2) at room temperature, under the mechanical stirring condition of 600r / min, add 2mg / ml TPP 120ml to above-mentioned chitosan solution, react for 60min, the system has obvious blue opalescence generation, obtains nanosuspension;

[0058] (3) The nanosuspension obtained in step (2) is concentrated by rotary evaporation at a temperature of 75° C., and the volume is evaporated to half of the volume of the nanosuspension;

[0059] (4) The concentrated solution obtained in step (3) is spray-dried, the inlet temperature is set to 140°C, the outlet temperature is 110°C, the injection flow rate is 1000ml / h, the pressure is 5atm, and the wind speed is 0.65m 3 / min. The resulting spray-dried chitosan nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com