Three-section simulated moving bed chromatography device

A technology for simulating a moving bed and a chromatographic device, which is applied in the field of chromatographic separation devices, can solve the problems of decreased product purity, inability to perform steady-state operation, and decreased separation efficiency, and achieve the effect of improving the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

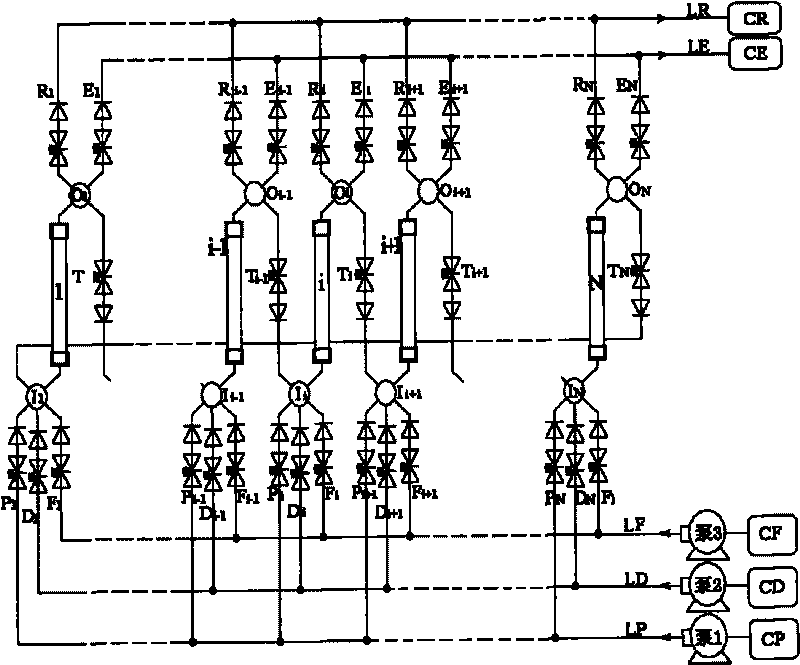

[0041] Such as Figure 2-b As shown, a pump 1 is a three-band simulated moving bed device with 8 chromatographic columns of a gradient pump, the pump 1 is a binary gradient pump, and the liquid storage tank CP of solution A A and solution B reservoir CP B Connect, other structures are with embodiment 1.

Embodiment 3

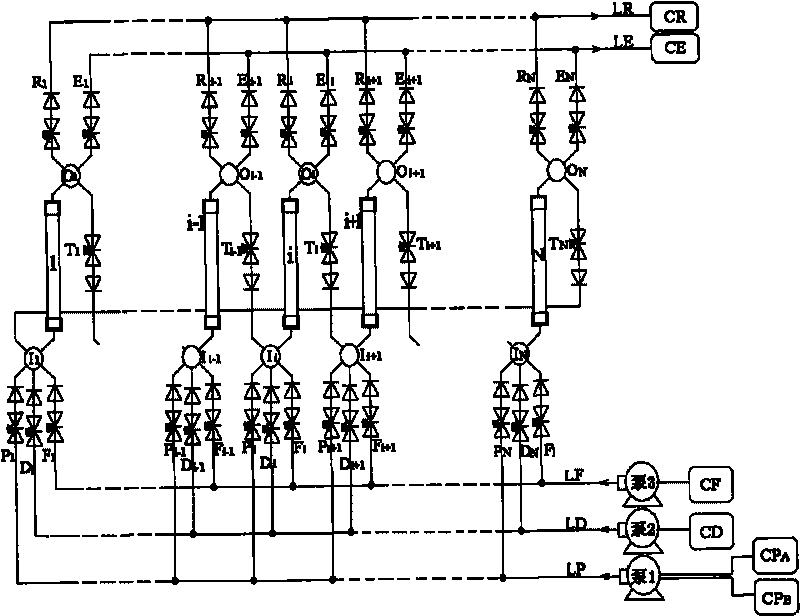

[0043] Such as Figure 2-c As shown, a three-band simulated moving bed chromatographic device with pump 1 connected to a liquid storage tank CP is equipped with 8 chromatographic columns with their own temperature control boxes, and the 8 chromatographic columns are equipped with their own temperature control boxes H 1 -H 8 , other structures are the same as embodiment 1.

[0044] Three-band simulated moving bed chromatographic device embodiment 4

[0045] Such as Figure 2-d As shown, a kind of pump 1 is a diagram of a three-band simulated moving bed chromatographic device equipped with 8 chromatographic columns of their respective temperature control boxes, and the 8 chromatographic columns are equipped with their respective temperature control boxes H 1 -H 8 , other structures are the same as embodiment 2.

Embodiment 5

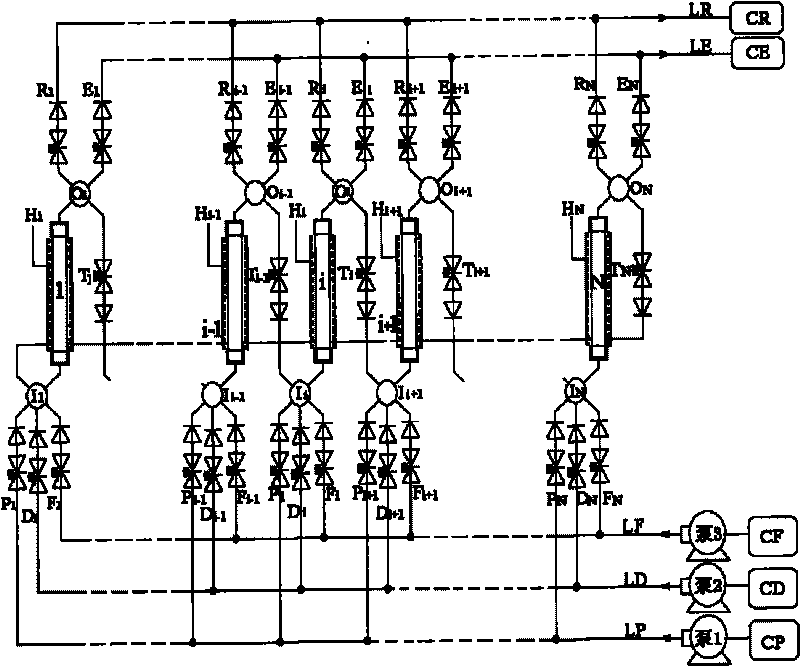

[0047] Such as Figure 2-e As shown, a pump 1 is equipped with a filter, an online degasser, a flowmeter on the circulation pipeline, a flowmeter on the total output pipeline, and a solution concentration and purity detector on the total input pipeline connected to a liquid storage tank CP Three-band simulated moving bed setup with 8 columns. The liquid storage tank CP is connected to the pump 1 through the online degasser DG1, and the pump 1 is connected to the eluent P input main pipeline LP through the filter F1; the liquid storage tank CD is connected to the pump 2 through the online degasser DG2, and the pump 2 The filter F2 is connected to the eluent D input main pipeline LD; the liquid storage tank CF is connected to the pump 3 through the online degasser DG3, and the pump 3 is connected to the raw material liquid F input main pipeline LF through the filter F3. The above three online degassers The air machine can also be replaced by a three-channel online degasser; a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com