Mesoporous molecular sieve catalyst, preparation method thereof and application thereof in preparing aldehyde ketone

A mesoporous molecular sieve and catalyst technology, applied in the field of preparation of the catalyst, can solve the problems such as the inability to obtain high selectivity of aldehydes and ketones at the same time, the complex preparation process of the catalyst, and the unfavorable chemical industry production, etc. The effect of recovery and high catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

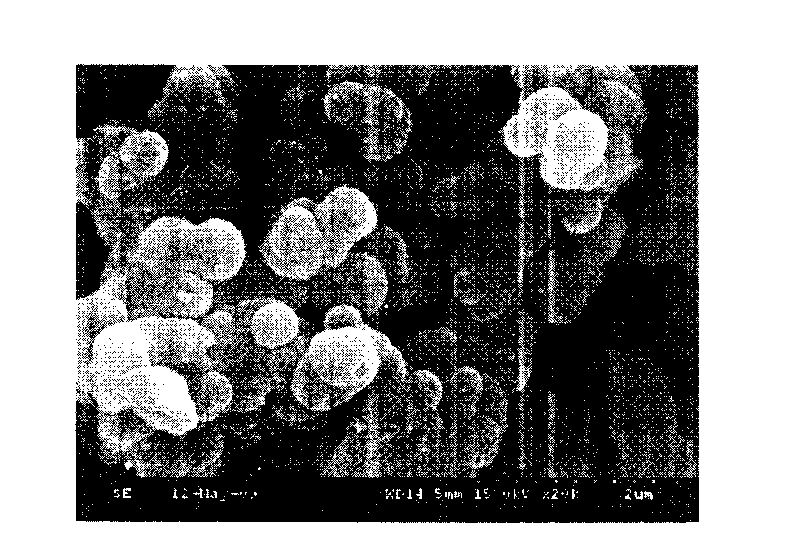

[0020] Embodiment 1: Preparation of silver-containing HMS mesoporous molecular sieve catalyst

[0021] 30°C water bath, magnetic stirring, mix and dissolve 5.00g template dodecylamine, 72mL water and 41.46g absolute ethanol, stir until clear; add 0.80g silver nitrate, continue stirring for 2h to form a gel; Add 20.88g tetraethyl orthosilicate dropwise at a high speed, continue to stir for 24 hours at a temperature of 30°C; crystallize for 24 hours at a crystallization temperature of 30°C, filter, wash, dry, and roast at 550°C for 6 hours to remove the template agent, and granulate for 40~ 60 mesh, the obtained catalyst is recorded as: Ag(I)-HMS.

Embodiment 2

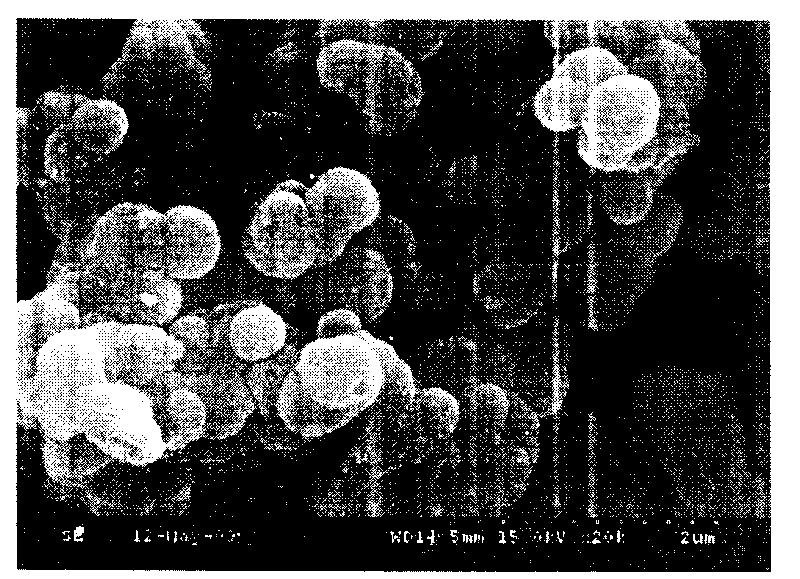

[0022] Embodiment 2: Preparation of silver-containing HMS mesoporous molecular sieve catalyst

[0023] The synthetic method of catalyst is as embodiment 1, selects silver sulfate, silver fluoride, silver perchlorate successively as silver source, and the synthesized catalyst is respectively marked as: Ag(II)-HMS, Ag(III)-HMS, Ag( IV) - HMS.

Embodiment 3

[0024] Embodiment 3: Preparation of silver-containing HMS mesoporous molecular sieve catalyst

[0025] The synthetic method of catalyzer is as embodiment 1, changes the add-on of silver nitrate, is successively: 3.40g, 1.70g, 0.68g, 0.34g, 0.17g, 0.09g, and gained catalyzer is respectively marked as: 1-Ag(I)- HMS, 2-Ag(I)-HMS, 3-Ag(I)-HMS, 4-Ag(I)-HMS, 5-Ag(I)-HMS, 6-Ag(I)-HMS.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com