Reagent for preventing or reducing scum generation

A technology of scum and powder, which is applied in the field of reagents used to prevent or reduce the generation of scum, which can solve the problems such as difficulty in suppressing scum, and achieve the effect of active activity and promotion of decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

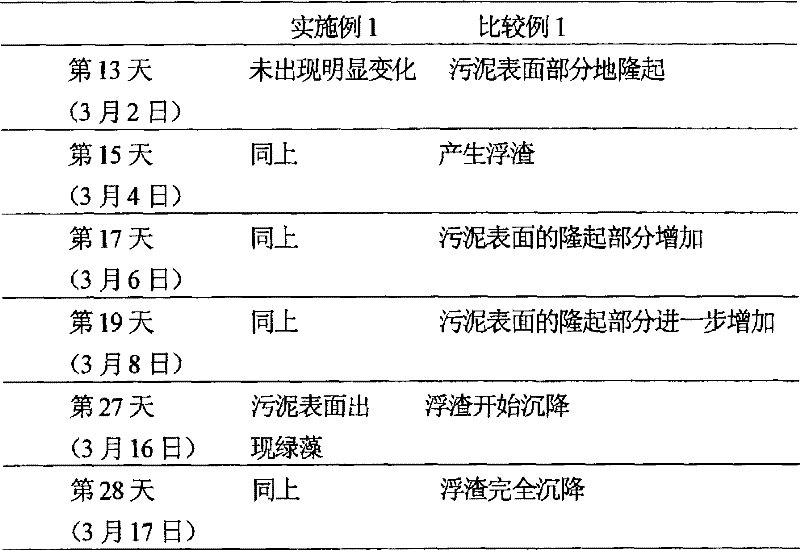

Examples

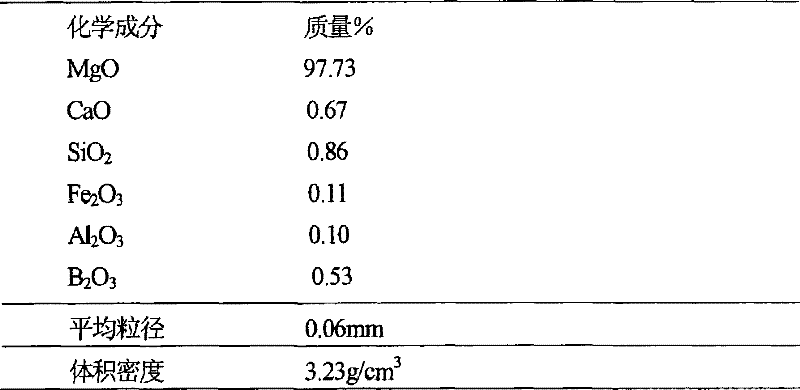

Embodiment 1

[0028] According to a conventional method, milk of lime was poured into seawater to prepare a magnesium hydroxide slurry, and the obtained slurry was washed, filtered, and dried to obtain magnesium hydroxide powder having a purity of 95.0% by mass or more in terms of magnesium oxide. The obtained magnesium hydroxide powder was press-molded to a granular product with a particle diameter of 5 to 10 mm, and then fired at a temperature of 1800° C. using a rotary kiln to obtain a granular fired product (slag) of magnesium oxide. The obtained magnesia slag was classified by a sieve with a mesh size of 0.75 mm, and a dead-burned magnesia powder having properties shown in Table 1 below was obtained under the sieve. The average particle size in the following table 1 is to use the sieves with meshes of 1.00mm, 0.50mm, 0.30mm, 0.15mm, 0.075mm, and 0.045mm, and use the sieving method to measure the particle size distribution, and make the cumulative distribution curve of the part on the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com