Synthesis method of sweet taste inhibitor 2-(4- methoxyphenyl) sodium propionate

A technology of methoxyphenyl and sweetness inhibitor, which is applied in the field of compound preparation and can solve the problem of low purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1 (control test)

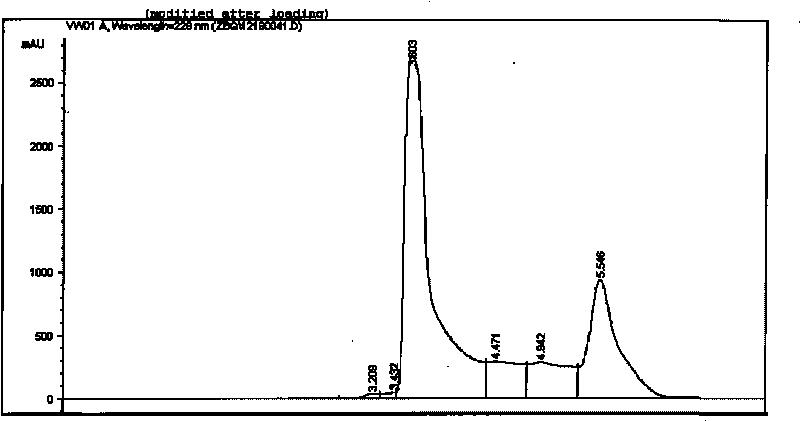

[0015] Put 6.2g (50mmol) of p-methoxyphenol, 6.1g (55mmol) of 2-chloropropionic acid, 2.3g (58mmol) of sodium hydroxide, and 40mL of deionized water in a 100mL single-necked flask, heat and reflux for about 6h, and the reaction ends Afterwards, the pH value was adjusted to 2.0 with food-grade hydrochloric acid to produce a large amount of viscous white solid, which was filtered to obtain 6.0 g of viscous white solid 2-(2-methoxyphenyl)propionic acid. Productive rate 66.67%, product is mixture (see attached figure 1 shown). Then the resulting viscous 2-(4-methoxyphenyl)propionic acid was dissolved in an equimolar aqueous sodium hydroxide solution, and after dissolution, the water was evaporated at 80°C to obtain the sweetness inhibitor 2-(2- Sodium Methoxyphenyl) Propionate.

Embodiment 2

[0016] Embodiment 2 (the present invention)

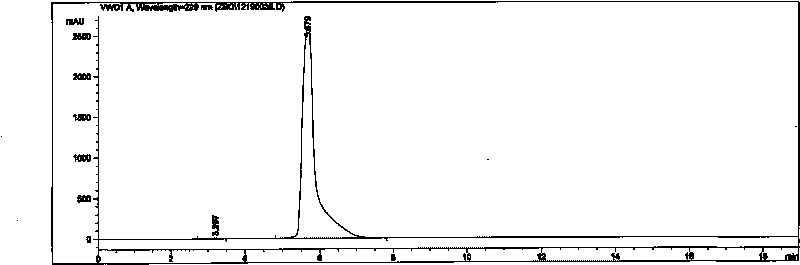

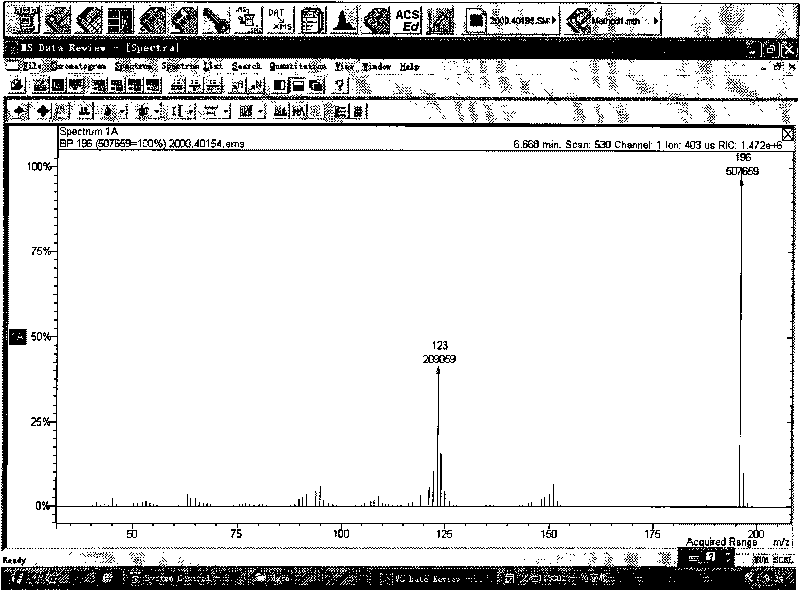

[0017] 6.2g (50mmol) of p-methoxyphenol, 7.7g (55mmol) of ethyl 2-chloropropionate, and 8.0g (58mmol) of potassium carbonate. Catalyst potassium iodide 0.1g, absolute ethanol 40mL in a 100mL single-necked flask, heated to reflux for about 6 hours, until the reaction of ethyl 2-chloropropionate was basically complete by thin-layer chromatography, cooled, filtered, and the filtrate was distilled to recover ethanol. Add 50 mL of ethyl acetate and 60 mL of deionized water to the solid obtained from the above filtration, and statically separate the layers. Collect the water layer and adjust the water layer to a pH value of 2.0 with food-grade hydrochloric acid. A large amount of white solids are produced. Add ether to dissolve the Solid, 40 mL each time, extracted three times in total, then washed the collected ether layer twice with 20 mL of deionized water to remove residual potassium ions, distilled off the ether to obtain white soli...

Embodiment 3

[0018] Embodiment 3 (the present invention)

[0019] 6.2g (50mmol) of p-methoxyphenol, 7.7g (55mmol) of ethyl 2-chloropropionate, and 8.0g (58mmol) of potassium carbonate. Catalyst sodium iodide 0.1g, absolute ethanol 40mL in a 100mL single-necked flask, heated to reflux for about 6 hours, until the reaction of ethyl 2-chloropropionate was basically complete by thin-layer chromatography, cooled, filtered, and the filtrate was distilled to recover ethanol. Add 50 mL of ethyl acetate and 60 mL of deionized water to the solid obtained from the above filtration, and statically separate the layers. Collect the water layer and adjust the water layer to a pH value of 2.0 with food-grade hydrochloric acid. A large amount of white solids are produced. Add ether to dissolve the Solid, 40 mL each time, extracted three times in total, then washed the collected ether layer twice with 20 mL of deionized water to remove residual potassium ions, distilled off the ether to obtain white solid 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com