Method for synthesizing cyclic carbonate ester in presence of acidic ionic liquid catalyst

A technology of acidic ionic liquid and cyclic carbonate, applied in the direction of organic chemistry, can solve the problems of environmental pollution cost, low catalyst activity, harsh reaction conditions, etc., and achieve the effect of reducing production cost, high reactivity and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

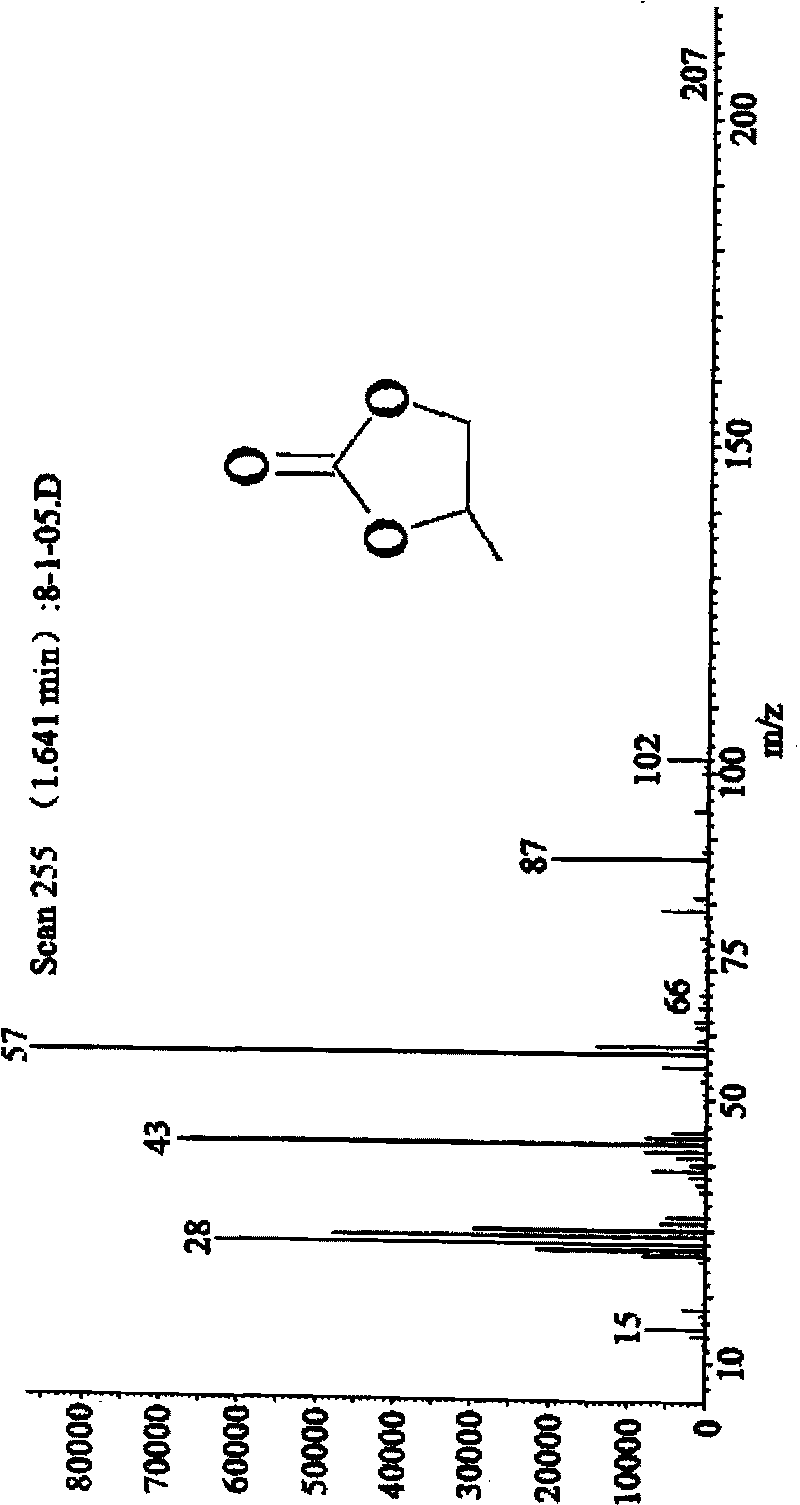

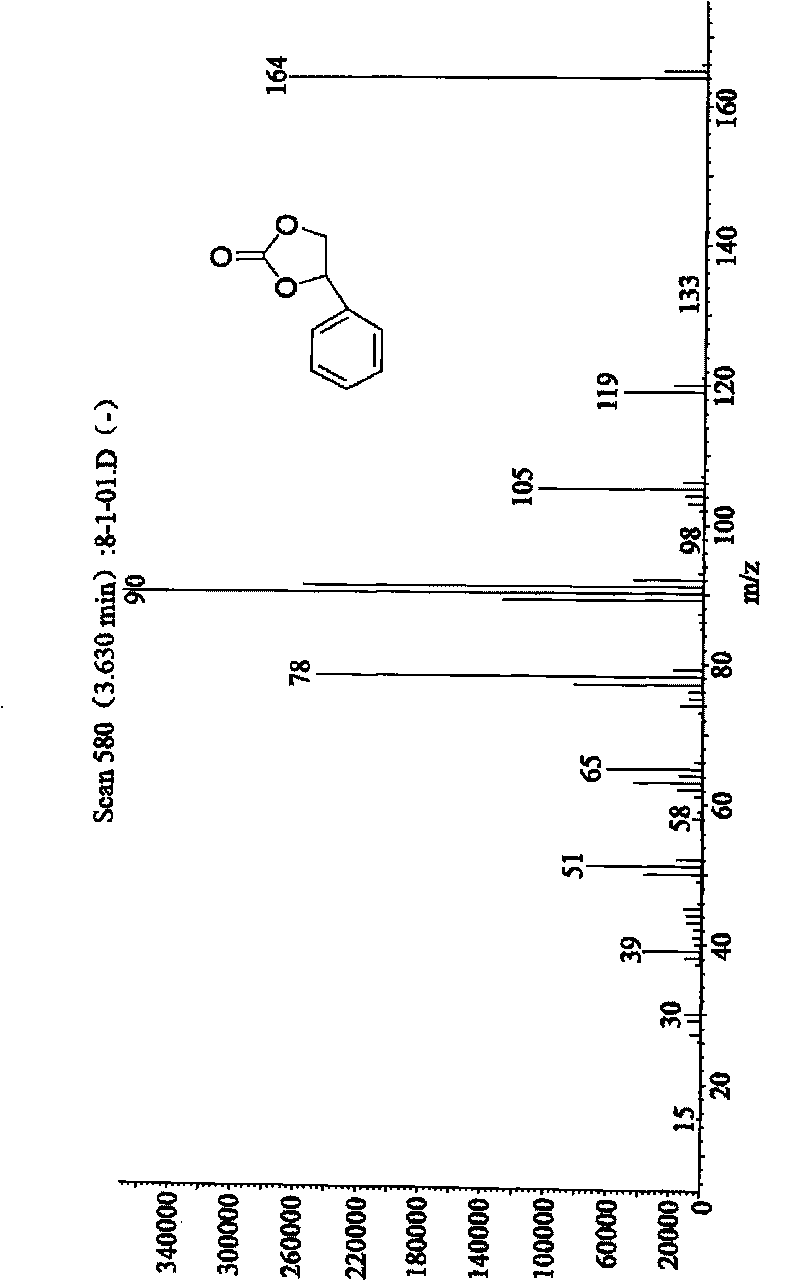

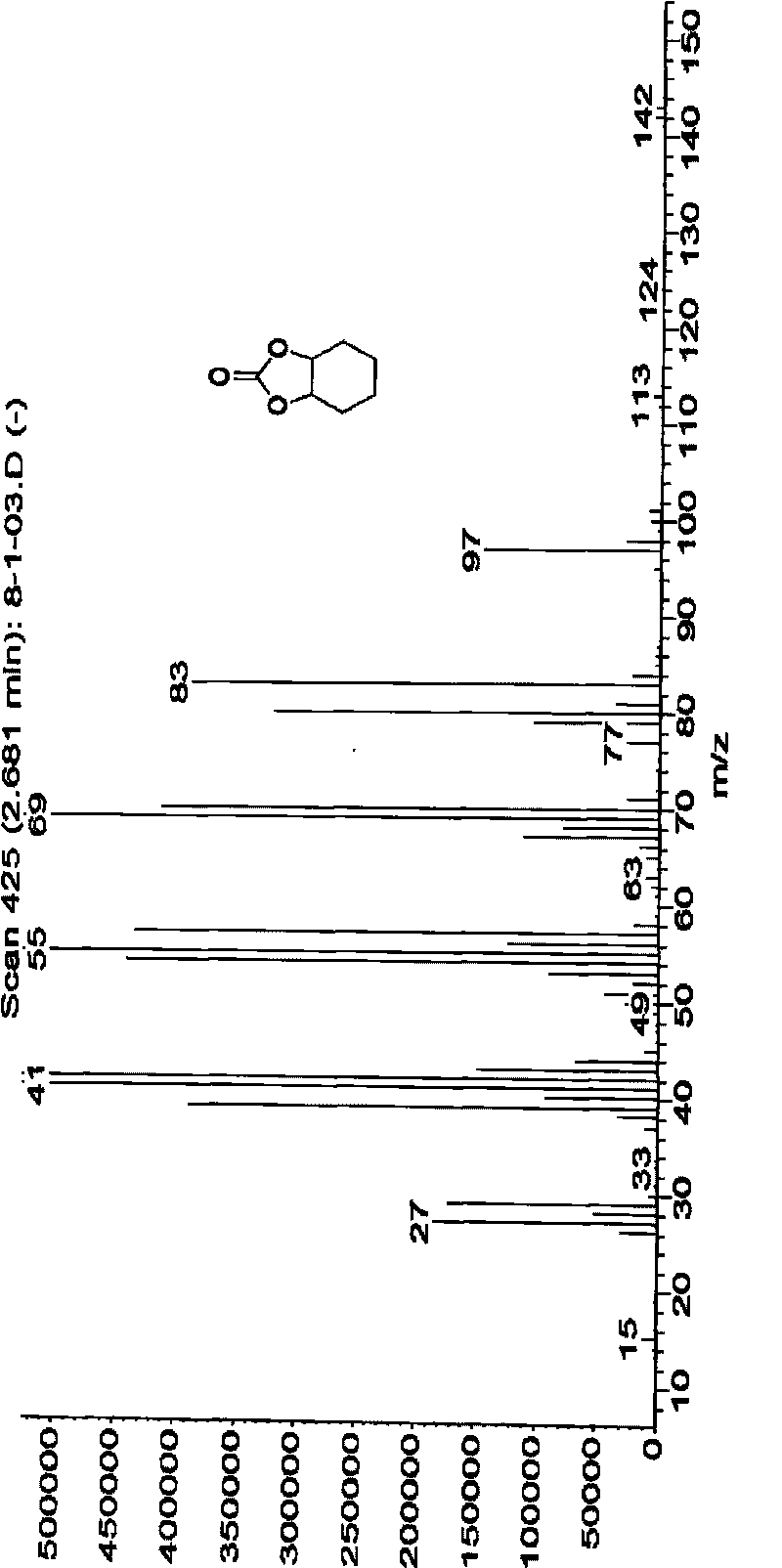

Image

Examples

specific Embodiment approach 1

[0008] Specific implementation mode one: in this implementation mode The method for the catalyzed synthesis of cyclic carbonates by acidic ionic liquids is as follows: add Acidic ionic liquid (as catalyst), then add epoxy compound, The molar ratio of the acidic ionic liquid to the epoxy compound is 1-10:100, the autoclave is sealed, the pressure in the autoclave is 0.1-10 MPa by feeding carbon dioxide, the heating rate is raised to the reaction temperature, the reaction temperature is 50-200 ° C, and the temperature is kept React at constant pressure for 0.5-10 hours, then cool the autoclave to room temperature, then slowly release carbon dioxide, and distill under reduced pressure to obtain a cyclic carbonate.

[0009] In this embodiment, the slow release of carbon dioxide is to prevent the product from being taken out.

specific Embodiment approach 2

[0010] Specific implementation mode two: the difference between this implementation mode and specific implementation mode one is: the The molar ratio of the acidic ionic liquid to the epoxy compound is 2-8:100. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific implementation mode three: the difference of this implementation mode specific implementation mode one is: the The molar ratio of the acidic ionic liquid to the epoxy compound is 4-7:100. Other steps and parameters are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com