Waterborne polyurethane modified epoxy steel structure anti-corrosive paint and preparation method thereof

A water-based polyurethane and anti-corrosion coating technology, applied in the coating field, can solve the problems of poor anti-aging, anti-pulverizing performance and insufficient flexibility, and achieve the effects of low price, improved safety and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

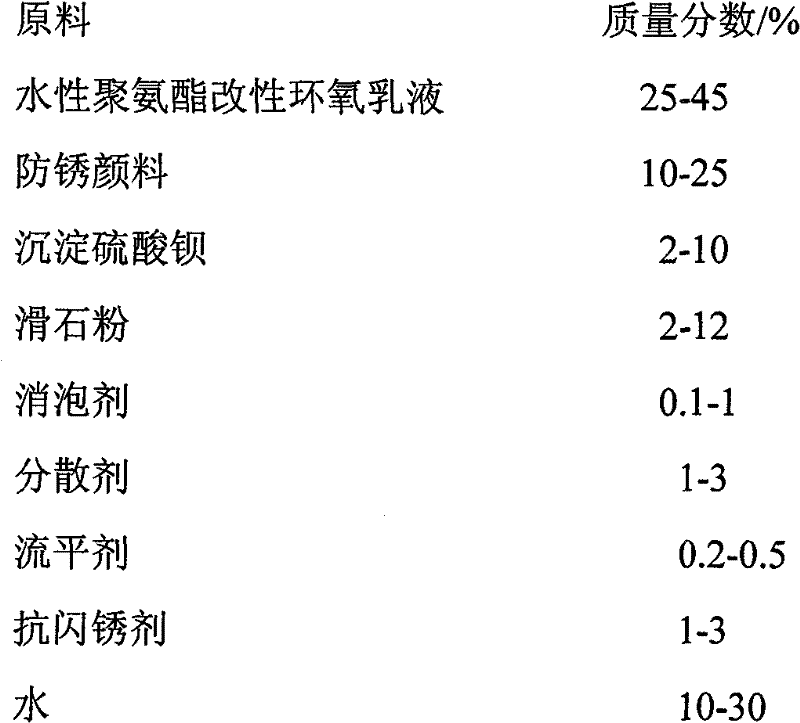

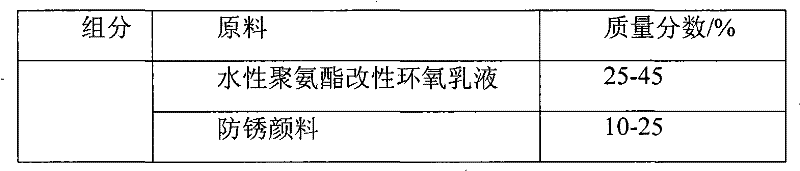

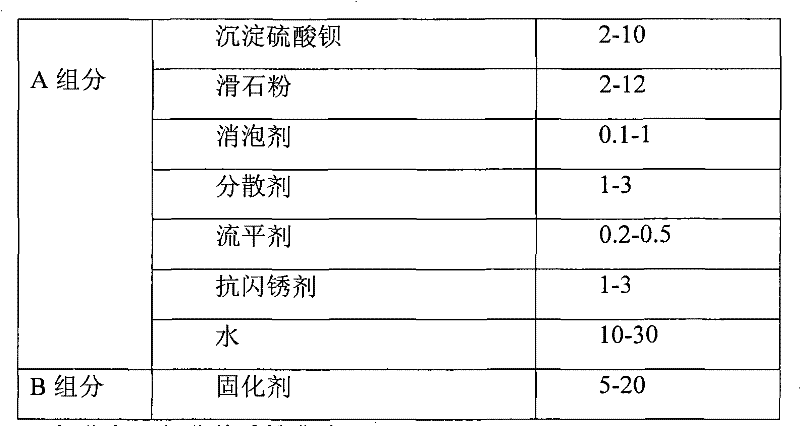

[0034] Take the following raw materials by weight unit: water-based polyurethane modified epoxy emulsion 25; precipitated barium sulfate 10; antirust pigment 22; talc powder 8; defoamer 1; dispersant 2.5; , water 18. The leveling agent is BYK346, the dispersant is AFCONA-4560, the anti-flash rust agent is raybo75, and the defoamer is Defom W-0505.

[0035] Under high-speed stirring, sequentially mix zinc powder, anti-rust pigment, talcum powder, anti-flash rust agent, dispersant and water into the water-based polyurethane modified epoxy emulsion and add half of the defoamer to disperse the pigment to 50 mesh Next, at a stirring rate of 300r / min-500r / min, add the other half of defoamer and leveling agent and other additives. Stir evenly, and obtain A component after filtration.

[0036] A water-based dispersion was prepared after capping and addition of polyacrylamide and emulsifying with a reactive emulsifier. Mix 7 g of the dispersion with 4 g of water to form group B.

[...

Embodiment 2

[0048] Weigh the following raw materials by weight unit: water-based polyurethane modified epoxy emulsion 35; precipitated barium sulfate 7; antirust pigment 16; talcum powder 4; defoamer 0.3; dispersant 1.5; ; water 15. The leveling agent is BYK346, the dispersant is AFCONA-4550 and AFCONA-5071, the anti-flash rust agent is raybo75, and the defoamer is DefomW-092.

[0049] Under high-speed stirring, sequentially mix precipitated barium sulfate, anti-rust pigment, talc powder, anti-flash rust agent, dispersant and water into the water-based polyurethane modified epoxy emulsion and add half of the defoamer to disperse the pigment to 50 Under the mesh, then add the other half of defoamer and leveling agent and other additives at a stirring speed of 300r / min-500r / min. Stir evenly, and obtain A component after filtration.

[0050] After capping and addition, emulsify with a reactive emulsifier to prepare a water-based dispersion. Mix 10 g of the dispersion with 10 water to form ...

Embodiment 3

[0062] Weigh the following raw materials by weight unit: water-based polyurethane modified epoxy emulsion 45; precipitated barium sulfate 6; antirust pigment 12; talcum powder 4; defoamer 0.3; dispersant 1.5; ; water 10. The leveling agent is BYK346, the dispersant is AFCONA-4550 and AFCONA-5071, the anti-flash rust agent is raybo75, and the defoamer is DefomW-092.

[0063] Under high-speed stirring, sequentially mix precipitated barium sulfate, anti-rust pigment, talc powder, anti-flash rust agent, dispersant and water into the water-based polyurethane modified epoxy emulsion and add half of the defoamer to disperse the pigment to 100 Mesh below, and then at 300r / min-500r / min stirring speed, add the other half of defoamer and leveling agent and other additives. Stir evenly, and obtain A component after filtration.

[0064] A water-based dispersion was prepared after capping and addition of polyacrylamide and emulsifying with a reactive emulsifier. 13 g of the dispersion was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com