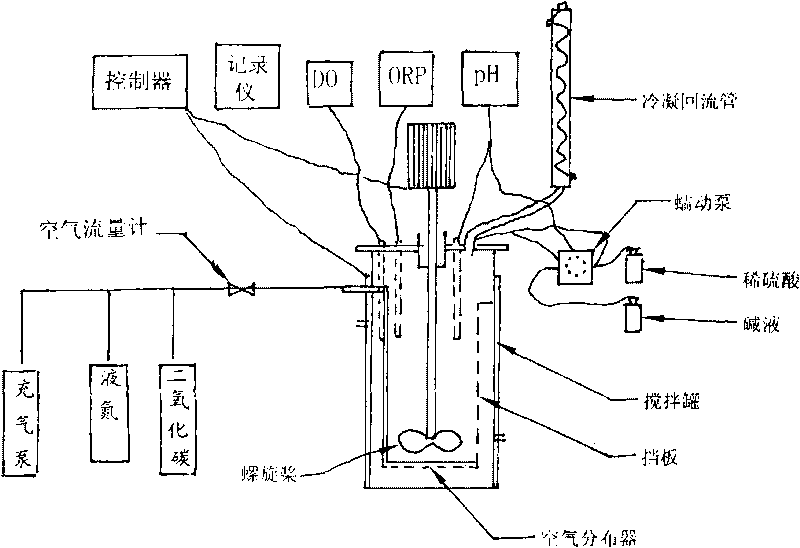

Bacterial agitation leaching experimental facility and method for measuring oxygen mass transfer coefficients

An experimental device, stirring and leaching technology, applied in biochemical cleaning devices, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve problems such as inability to carry out online control and measurement, and achieve stability and operability performance, avoid water evaporation loss, and reduce the effect of operating steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Medium thermophilic bacteria (please refer to Chinese patent, its application number is 200610078976.6) stirring and leaching chalcopyrite concentrate, the mineral particle size is less than 30μm, the pulp concentration is 5% (m / v), and the aeration volume is 0.5m 3 Under the experimental conditions of / h, adjust the pH value of the ore slurry to the optimum pH value of bacteria (1.70-2.00); put the domesticated and cultured leaching bacteria in the exponential growth phase into the stirring tank, the inoculation rate is average Between 5% and 10% (v / v); start aeration, set the temperature at the optimum growth temperature for bacteria, start heating and measure bacterial growth, pH, ORP and DO;

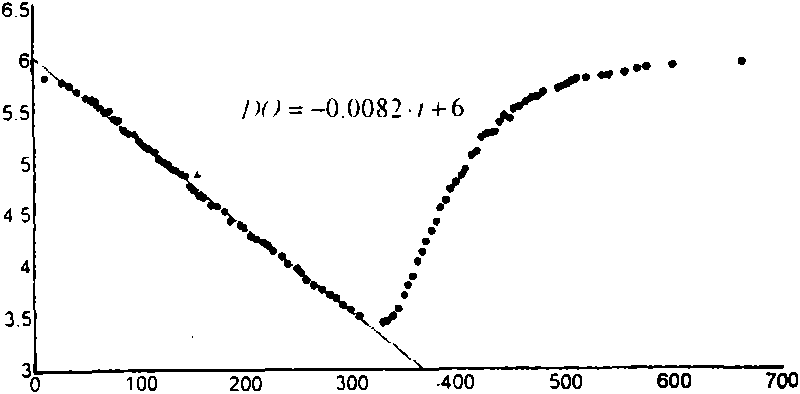

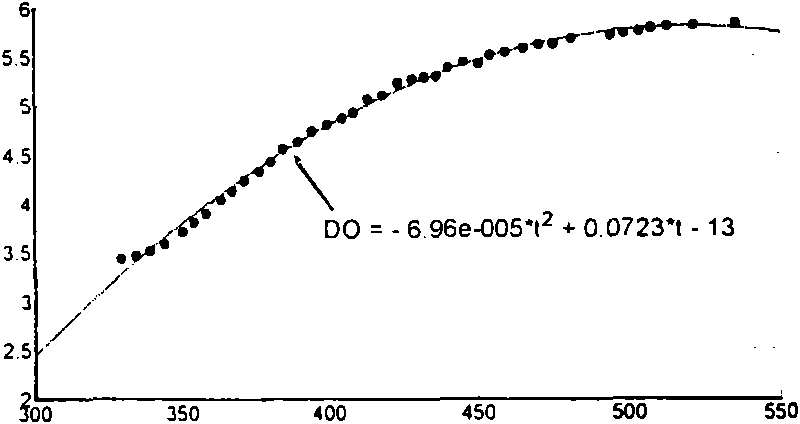

[0028] After the bacterial growth lag period, the dissolved oxygen concentration of the leaching system will be maintained within a certain range. At this time, the aeration will be stopped, and the aeration will be resumed after the dissolved oxygen concentration drops to a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com