Preparation method of chromium-doped titanium nitride magnetic semiconductor polycrystal film

A technology of magnetic semiconductor and titanium nitride, which is applied in the field of preparation of chromium-doped titanium nitride magnetic semiconductor polycrystalline thin films, can solve the problem of no Cr-doped polycrystalline TiN thin films, etc. Choose Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

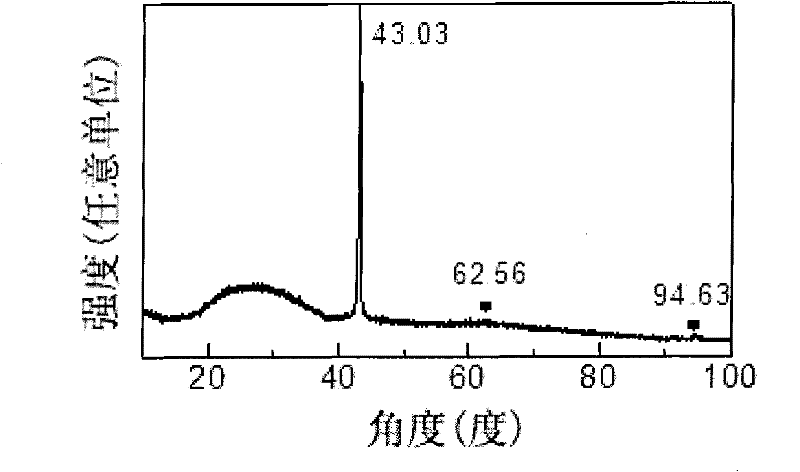

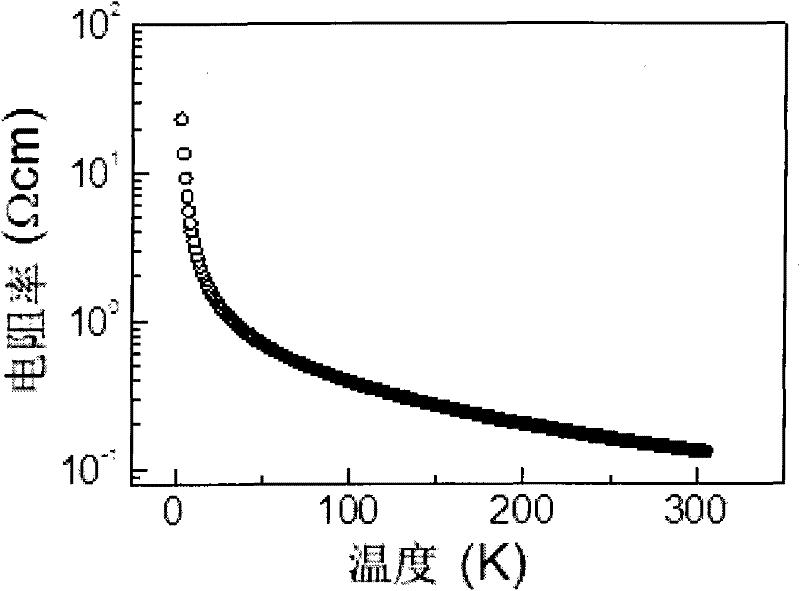

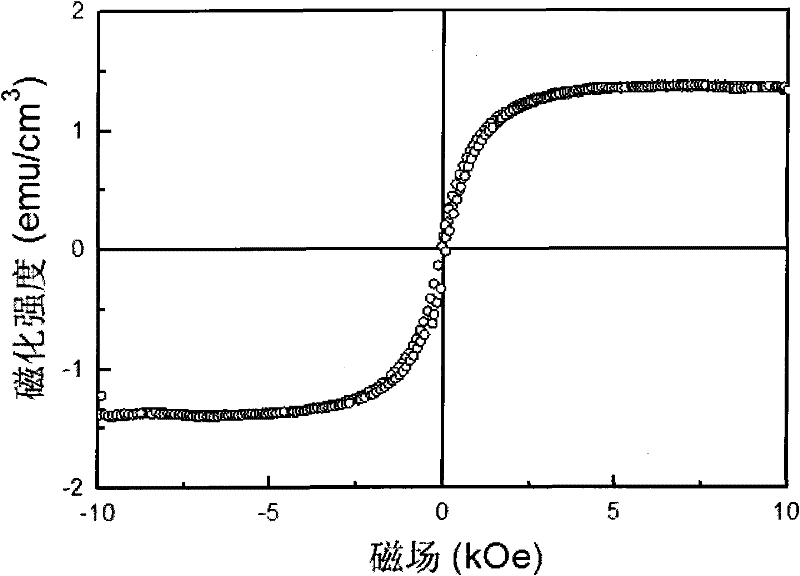

[0025] According to the structure and property analysis that we carry out to the sample prepared in the present invention, the best implementation mode of preparing Cr-doped polycrystalline TiN thin film to target reactive sputtering method will be described in detail below:

[0026] 1) The DPS-I type ultra-high vacuum facing target magnetron sputtering coating machine produced by the Shenyang Scientific Instrument Research and Development Center of the Chinese Academy of Sciences is adopted. A pair of Ti targets with a purity of 99.99% are installed on the facing target heads, and one end is used as the magnetic force line. The N pole and the other end is the S pole; the thickness of the target is 5mm, and the diameter is 100mm; evenly place Cr sheets on the surface of the Ti target (the area of the Cr sheet is 9mm 2 ), the number of Cr sheets is 16, and the content of Cr in the sample is 14%; the distance between the two targets is 100mm, and the distance between the axis o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com