Black photo resist and preparation method and picture composition method thereof

A black photoresist, unsaturated technology, applied in optomechanical equipment, photosensitive materials for optomechanical equipment, optics, etc., can solve the problems of limited metal chromium resources, serious environmental pollution, etc., to improve photosensitivity and polymerization speed. , the surface morphology is good, the effect of improving the dispersion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

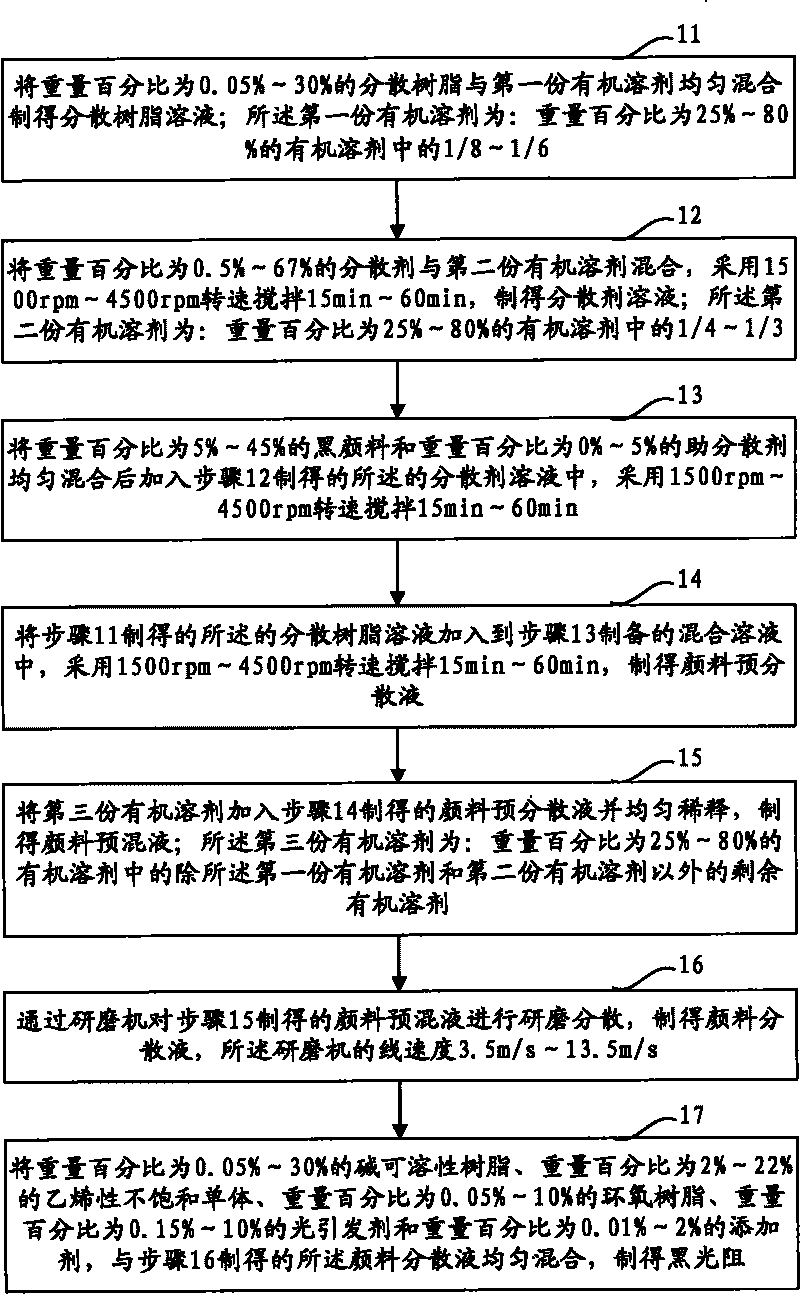

Method used

Image

Examples

no. 1 example

[0036]In this embodiment, the main components of the black photoresist are shown in column "1" of the embodiment in Table 1. The black photoresist of this embodiment comprises: the Regal 250 black pigment that is 12% by weight, the Solsperse 32600 dispersant that is 19.5% by weight, the SYNERGIST 5000 auxiliary dispersant that is 4% by weight, the ACAZ 200 that is 6.5% by weight and The dispersion resin that is the CN2279 mixing of 1% by weight, the PMA that is 16% by weight and the organic solvent that EEP is mixed of 15% by weight, the SB 401 alkali-soluble resin that is 18% by weight, the SB 401 alkali-soluble resin that is 2% by weight DPHA mixed with 0.5% by weight of EB 350 ethylenically unsaturated monomer, 1.2% by weight of DEN 438 epoxy resin, 1.2% by weight of Ciba 379 and 2.8% by weight of CGI 242 photoinitiator, and 0.3% by weight of antioxidants, wetting agents and other additives.

[0037] After testing, the particle size (average particle size) of the black pho...

no. 5 example

[0048] In this embodiment, the main components of the black photoresist are shown in column "5" of the embodiment in Table 1. The black photoresist of this embodiment comprises: 10.5% by weight of Regal 250 and 1.5% by weight of P.B 15:2 mixed black pigment, 18% by weight of Solsperse 32600 dispersant, 4.5% by weight of CN2279 dispersion Resin, 41% by weight of PMA organic solvent, 18% by weight of SB 401 alkali-soluble resin, 0.5% by weight of DPHA and 0.5% by weight of EB 350 mixed ethylenically unsaturated monomers, 1.2% by weight of DEN 438 epoxy resin, 4% by weight of CGI 242 mixed photoinitiator, and 0.3% by weight of antioxidants, wetting agents and other additives.

[0049] After testing, the particle size (average particle size) of the black photoresist in this embodiment is 44nm, and the storage stability is high.

[0050] Further, in each embodiment of the above-mentioned black photoresist, the black pigment may include: carbon black or perylene black, or a mixture...

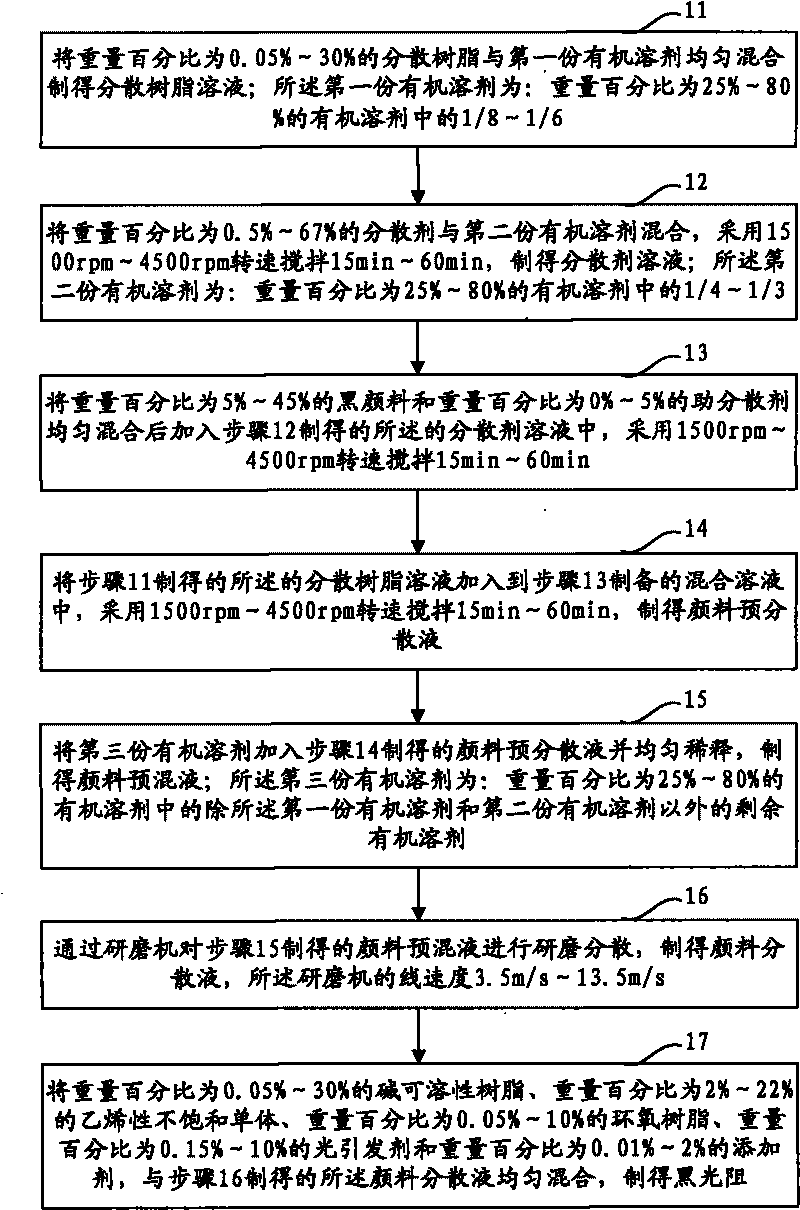

no. 1 example preparation

[0091]The main components of the first embodiment of the black photoresist are shown in column "1" of the embodiment in Table 1. In the first embodiment of the black photoresist of the present invention, a mixed solvent of 16% by weight of PMA and 15% by weight of EEP is selected as the organic solvent, these organic solvents are divided into three parts for use, and 1 / 6 of the organic solvent is measured As the first organic solvent, measure 1 / 3 of the organic solvent as the second organic solvent, and the remaining organic solvent as the third organic solvent. The preparation method of the first embodiment of the black photoresist of the present invention is as follows:

[0092] Step 111, uniformly mix the dispersion resin mixed with 6.5% by weight of ACAZ 200 and 1% by weight of CN2279 with the first part of organic solvent to prepare a dispersion resin solution; the first part of organic solvent It is: 1 / 6 of the organic solvent with a weight percentage of 25% to 80%;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com