Leaf-type solar wool-making device and method

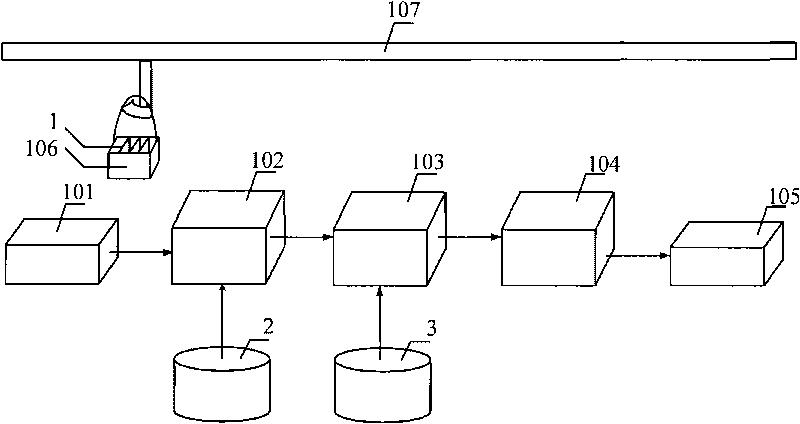

A technology of solar energy and single leaf, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve the problems of large amount of liquid medicine usage, unfavorable automatic connection, and capacity limitation, so as to improve the level of automation and reduce the cost of medicine Fluid consumption, good automatic connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

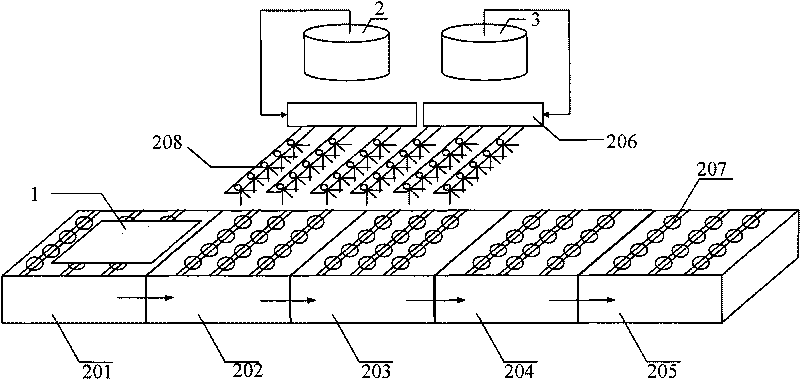

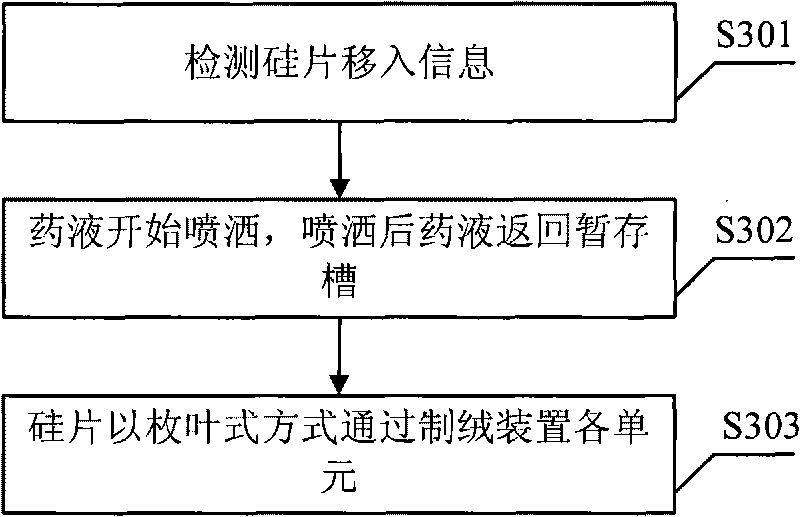

[0032] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0033] Such as figure 2 The structure diagram of the leaf-type solar texturing device of the shown embodiment one specifically includes:

[0034] The feeding unit 201 senses the silicon wafer transferred from the previous process and sends it to the texturing unit 202;

[0035] The texturing unit 202 sprays liquid medicine for texturing according to the set pressure, and the pressure setting range of the silicon wafer delivered by the feeding unit 201 is 0-0.6Mpa;

[0036] The cleaning unit 203 is used to clean the silicon wafers after the texturing unit has been textured; it includes an etching pickling unit, an etching alkali washing unit, and a pure water rinsing unit to clean the silicon wafers passing through the texturing unit 202;

[0037] The drying unit 204 is used to dry the silicon wafers cleaned by the cleaning unit 203, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com