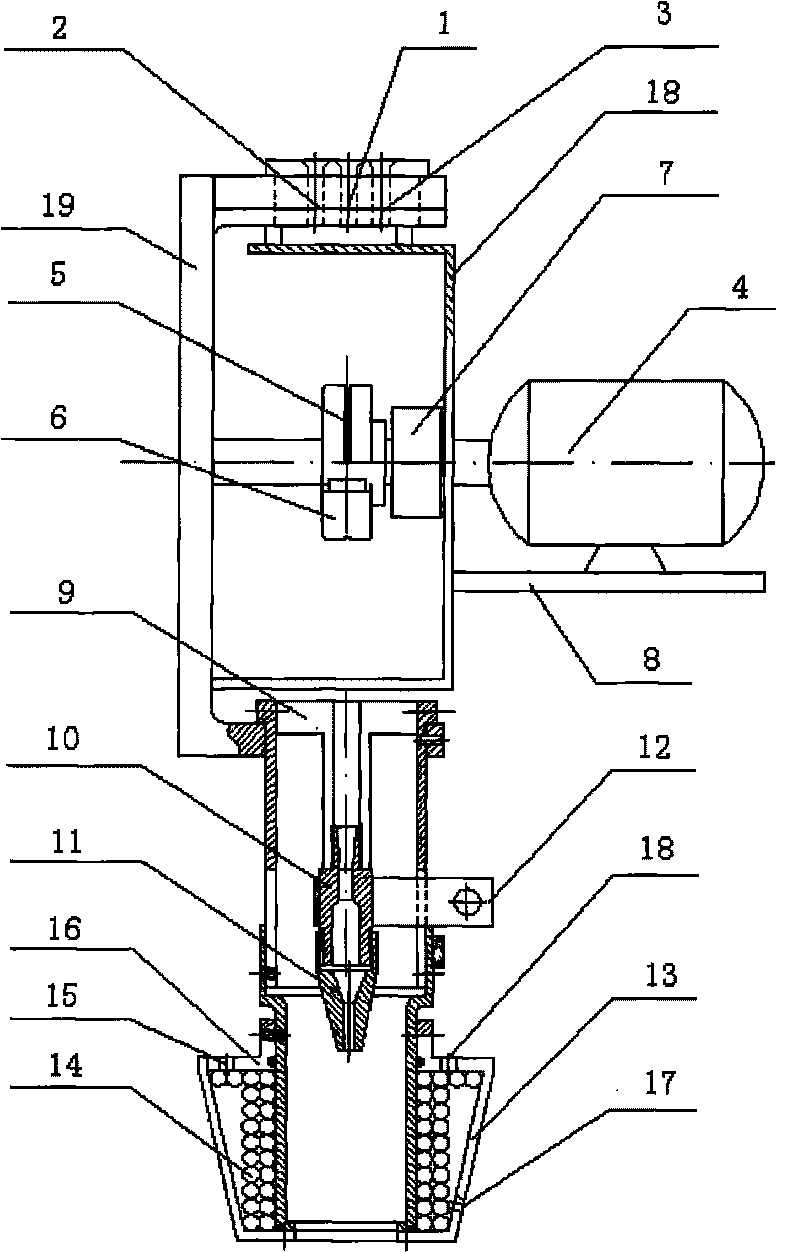

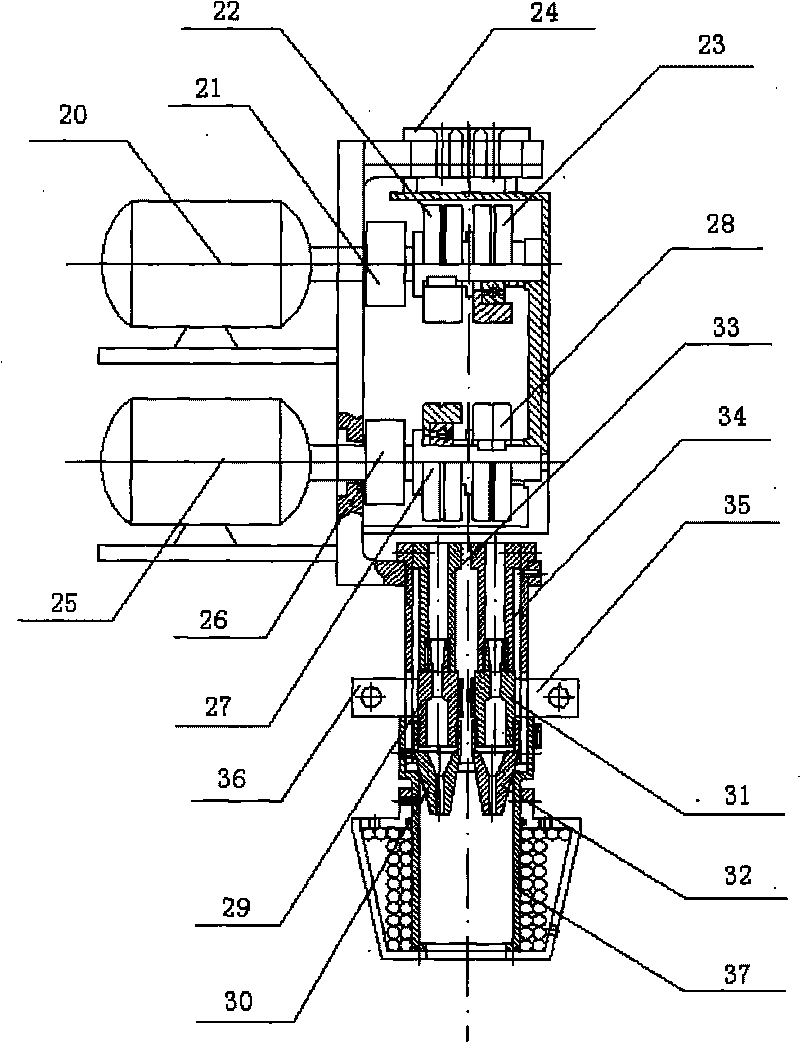

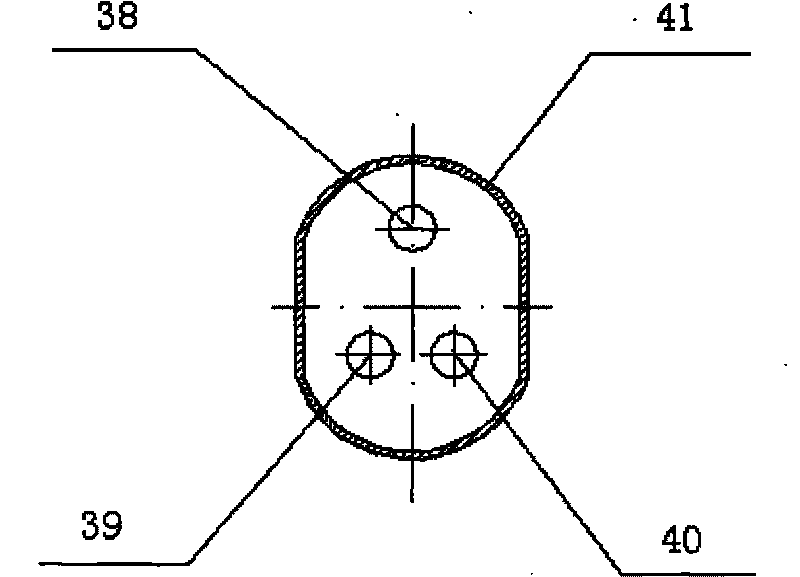

Electromagnetic direct-drive high-speed three-wire magnetic-field compound flux copper-gasket submerged arc welding device and method thereof

A submerged arc welding and electromagnetic composite technology, applied in arc welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult operation, narrow welding process specifications, coarse metal grains in the weld, etc., and achieve increased wire feeding. Friction, improved wire feeding stability, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0089] Example 1: Electromagnetic direct drive high-speed three-wire magnetic field composite flux copper liner submerged arc welding of 16MnR steel with a plate thickness of 30mm, the joint adopts Y-shaped groove, the assembly gap is 1mm, the end surface of the joint is machined to be smooth, and the end surface of the joint is cleaned before welding The back of the weld seam uses CaF2-MgO-CaO-Al2O3 slag-based high-strength steel sintered flux, and the flux copper pad is single-sided welded and double-sided forming process; welding wire I is used for bottom welding and cover welding, The DC welding current is 1200A, the excitation current is 20A, the magnetic field frequency is 20Hz, the welding wire II and III are DC welding current 850A, the wire diameter is 4mm, and the welding speed is 1.5m / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com