Method for digesting straws by earthworm

An earthworm and straw technology, applied in animal husbandry, biological sludge treatment and other directions, can solve problems such as low efficiency and straw decomposition, and achieve the effects of good growth, high digestion efficiency and more spawning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

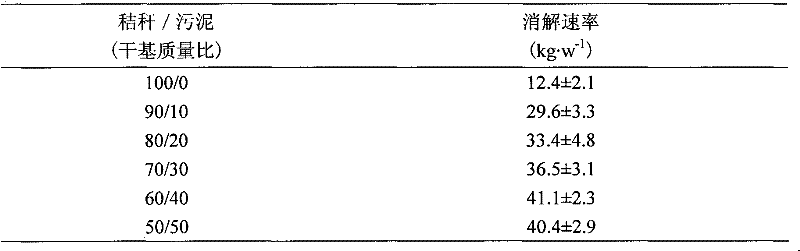

[0010] Example 1: Test of the material ratio of earthworm digestion straw

[0011] 1. Material

[0012] The experiment used "Daping No. 2" earthworms, provided by the earthworm breeding base of Yangzhou University Experimental Farm. Rice straw and sludge are taken from farmers and domestic sewage treatment plants.

[0013] 2. Method

[0014] A mixture of earthworms (2kg, calculated on a wet basis)-worm feces 84.7kg (50kg on a dry basis) was placed in a self-made wooden culture frame (100cm×100cm×40cm) with a 0.2mm aperture nylon screen as the bottom in advance. The rice straws and sludge that have been processed into 10cm long in advance are mass ratio (kg / kg) 66.3 / 0, 59.7 / 18.8, 53.1 / 37.6, 46.4 / 56.4, 39.8 / 75.2 and 33.2 / 94.0 (the combined dry basis mass ratio respectively) 100 / 0, 90 / 10, 80 / 20, 70 / 30, 60 / 40 and 50 / 50) fully mixed (equivalent to a dry weight of 50kg, in which the water content of straw and sludge are 24.6%, 73.4%, respectively) ) Is added to it, and when 1 / 4 of the su...

Embodiment 2

[0022] An example of the present invention is to build an earthworm bed of 500m per mu of land 2 , Mix 60% straw with 40% livestock manure or domestic sludge. The mixture is piled into long stacks about 20cm in height, 40cm in width and 3.5m in length, and each stack is about 15cm apart. Cover the mixture of domesticated working earthworms and earthworm feces on the long stacks of organic material mixtures such as straws at the same time. The input amount of earthworms is 0.5kg / m 2 Appropriate; the thickness of vermicompost covering should be 3-5cm. Too thick is not conducive to ventilation, and too thin will lose water quickly, which is detrimental to the survival of working earthworms. When vermicompost is covered, all the organic material mixture such as straw should be covered. When the organic material mixture such as straw is digested by about 50-60%, add the material immediately. When adding the material, add the organic material mixture such as straw and straw between the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com