Method for preparing single crystal perovskite type oxide and application thereof

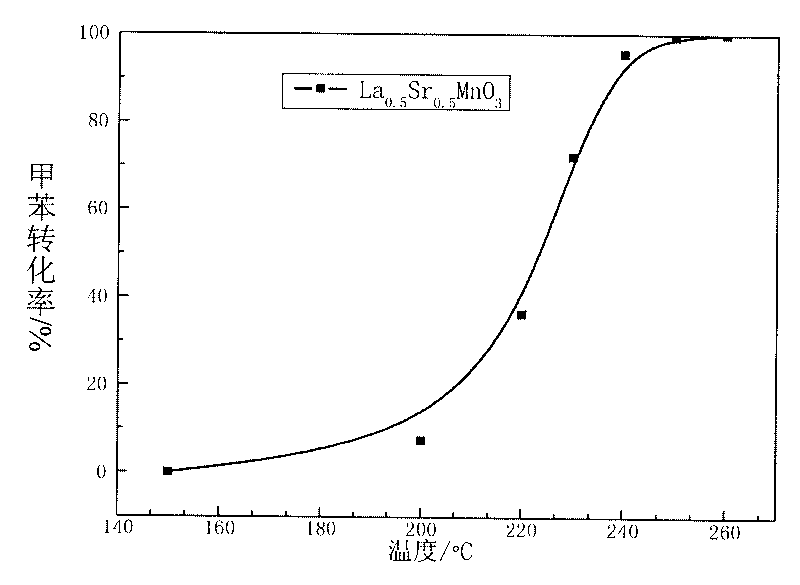

A perovskite type and oxide technology, which is applied in chemical instruments and methods, catalyst activation/preparation, single crystal growth, etc., can solve the problem that the low-temperature catalytic activity of perovskite type catalysts cannot meet the requirements of industrial applications, and achieve low temperature Efficient cleaning and purification treatment, good low temperature activity, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

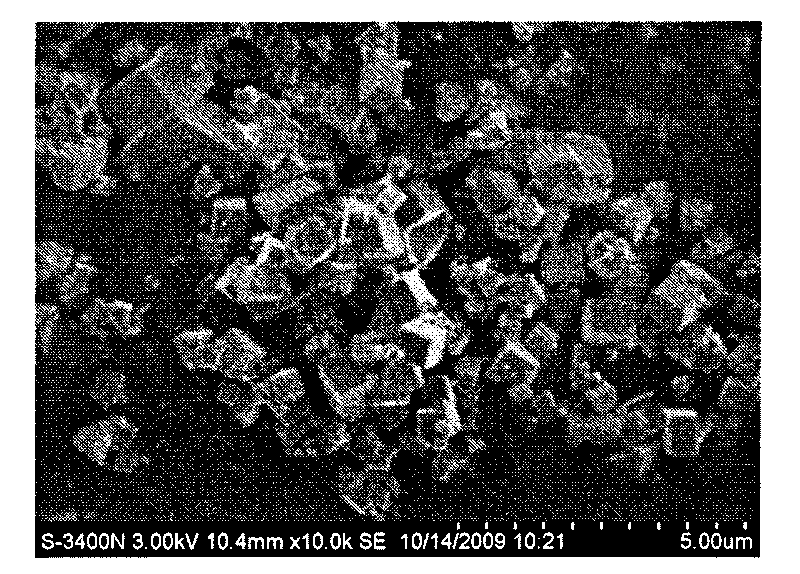

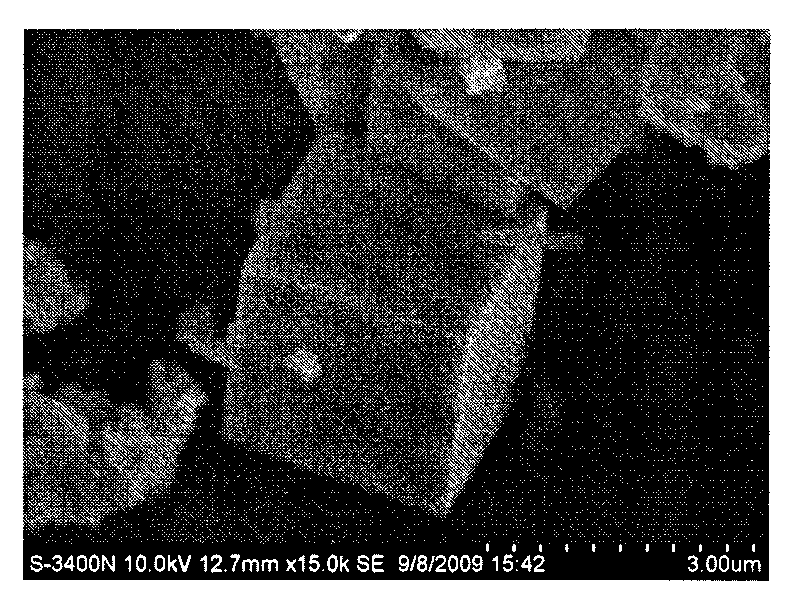

[0019] 0.003mol KMnO 4 , 0.007mol Mn(CH 3 COOH) 2 4H 2 O, 0.005molLa(NO 3 ) 3 ·6H 2 O, 0.005mol Sr(NO 3 ) 2 Dissolve in 20ml of deionized water, stir mechanically for 30min; dissolve 0.56mol NaOH in 50ml of deionized water, slowly add dropwise to the metal salt solution for 100min, put the mixed solution in the ultrasonic wave, ultrasonically disperse for 1h, and then move it into the reaction kettle In 220 °C hydrothermal reaction for 72 hours, naturally cooled to room temperature, the obtained product was centrifuged three times with deionized water and absolute ethanol, dried at 80 °C for 24 hours, and ground to obtain a black powder that is a single crystal perovskite oxide.

Embodiment 2

[0021] 0.003mol KMnO 4 , 0.007mol Mn(CH 3 COOH) 2 4H 2 O, 0.005molLa(NO 3 ) 3 ·6H 2 O, 0.005mol Sr(NO 3 ) 2 Dissolve in 20ml of deionized water, stir mechanically for 40min; dissolve 0.7mol NaOH in 50ml of deionized water, slowly drop into the metal salt solution for 80min, put the mixed solution into the ultrasonic wave, ultrasonically disperse for 30min, and then move it into the reaction kettle In 230 °C hydrothermal reaction for 56 h, naturally cooled to room temperature, the obtained product was centrifuged three times with deionized water and absolute ethanol, dried at 80 °C for 24 h, and ground to obtain a black powder that is a single crystal perovskite type oxide.

Embodiment 3

[0023] 0.003mol KMnO 4 , 0.007mol Mn(CH 3 COOH) 2 4H 2 O, 0.005molLa(NO 3 ) 3 ·6H 2 O, 0.005mol Sr(NO 3 ) 2 Dissolve in 20ml of deionized water, stir mechanically for 50min; dissolve 0.84mol NaOH in 50ml of deionized water, slowly add dropwise to the metal salt solution for 70min, put the mixed solution in the ultrasonic wave, ultrasonically disperse for 20min, and then move it into the reaction kettle In 240 ° C hydrothermal reaction for 48 h, naturally cooled to room temperature, the obtained product was centrifuged three times with deionized water and absolute ethanol, dried at 80 ° C for 24 h, and ground to obtain a black powder that is a single crystal perovskite oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com