Laser scanning scattering detection and classification system for silicon slice surface defects

A technology of silicon wafer surface, laser scanning, applied in scattering characteristic measurement, optical test defect/defect, optics, etc., can solve the problem of production line yield decline, etc., to achieve the effect of improving working voltage, good reliability and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

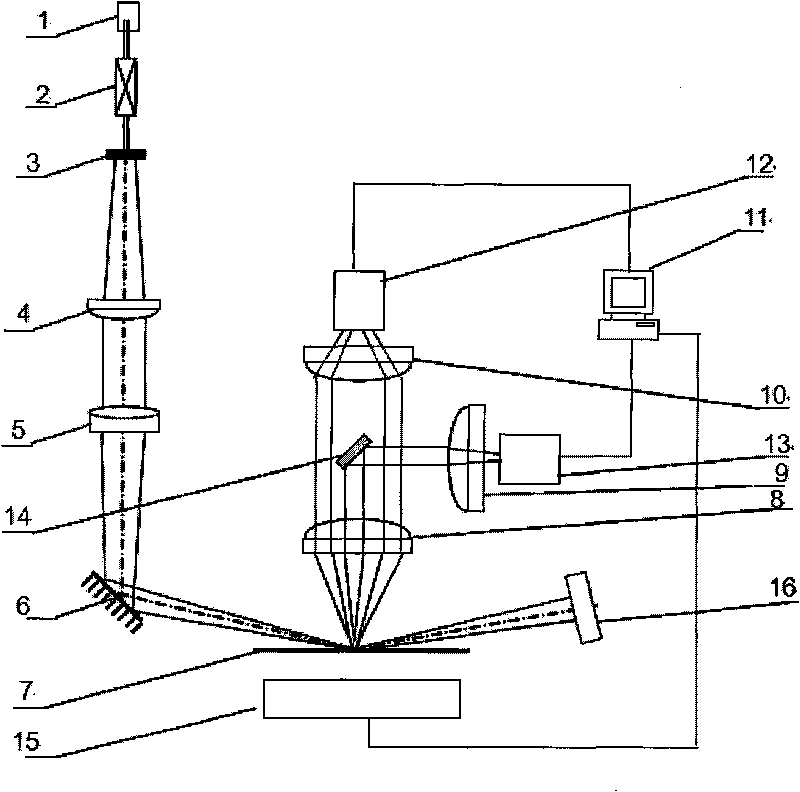

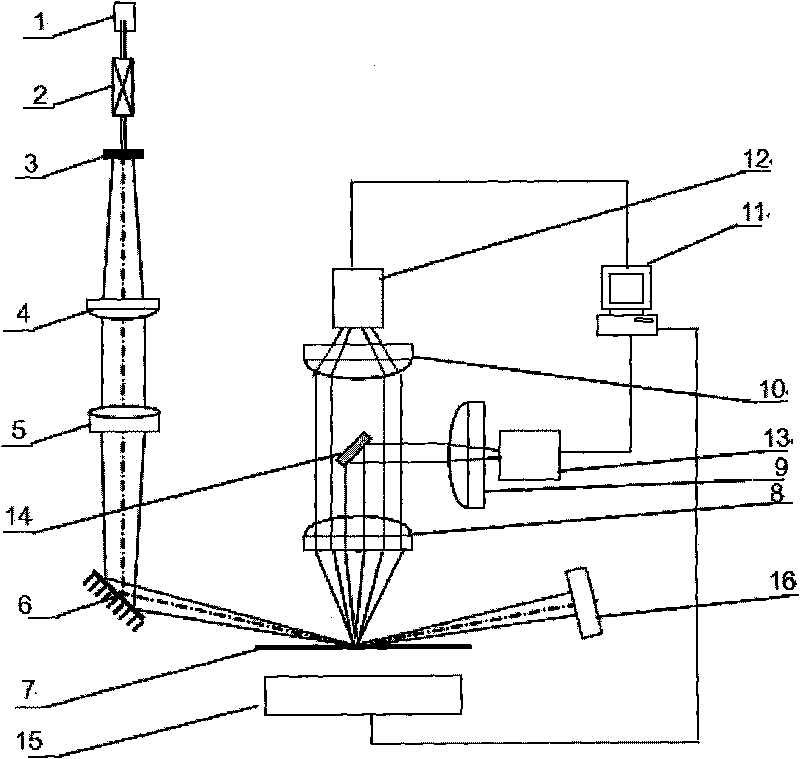

[0017] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail. like figure 1 The schematic diagram of the principle of the laser scanning scattering detection and classification system for the surface defect of the silicon wafer is shown, which is also the structural diagram of the preferred embodiment of the present invention. As can be seen from the figure, the structural composition of the system includes: the light beam sent by the laser light source assembly 1 advances In the direction of the direction, there is a beam expander system composed of a Faraday isolator 2, a double-concave lens 3 and a first plano-convex lens 4, a double-cement focusing lens 5, and the light beam is turned by a plane mirror 6 and obliquely focused and incident on the surface of the measured silicon wafer 7 , the silicon wafer 7 is located on the workbench 15; the scat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com