Material-flow mixing and dispersing device

An equipment and dispersing technology, applied in mixing methods, chemical/physical processes, dissolution, etc., can solve the problems of difficult to control the amount of liquid phase, poor mixing effect of gas-liquid flow, large degree of liquid phase deviation, etc. Short circuit, enhanced mixing effect, effect of slowing down fluid impulse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

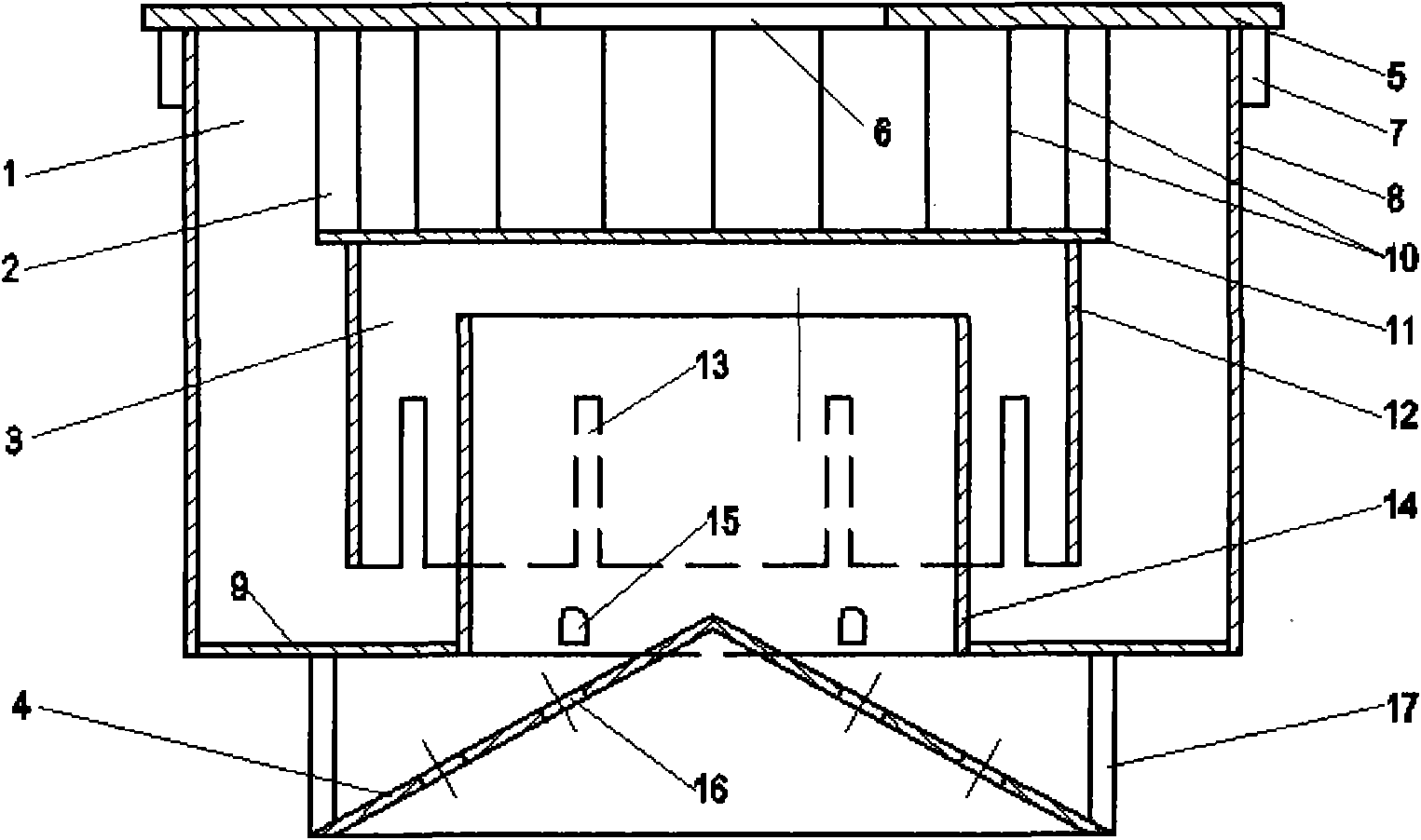

[0043] Example 1 illustrates the mixing effect of the gas-liquid flow mixing and dispersing equipment provided by the present invention.

[0044] Test method: using the gas-liquid flow mixing and dispersing equipment provided by the present invention, the structure is as follows figure 2 As shown, water and air are used as the simulated medium, and it is carried out in a cold mold test device with a diameter of 1000mm. The metered air and oxygen-enriched water pass through the gas-liquid flow mixing and dispersing equipment for oxygen desorption, and the dissolved oxygen analyzer is used to detect the dissolved oxygen concentration C in the inlet and outlet water of the gas-liquid flow mixing and dispersing equipment online. 入 、C 出 , Look up the table and get the equilibrium concentration of oxygen in the liquid phase C under the test conditions e , calculate the oxygen desorption efficiency according to the following formula, and analyze the change of liquid phase oxygen c...

Embodiment 2

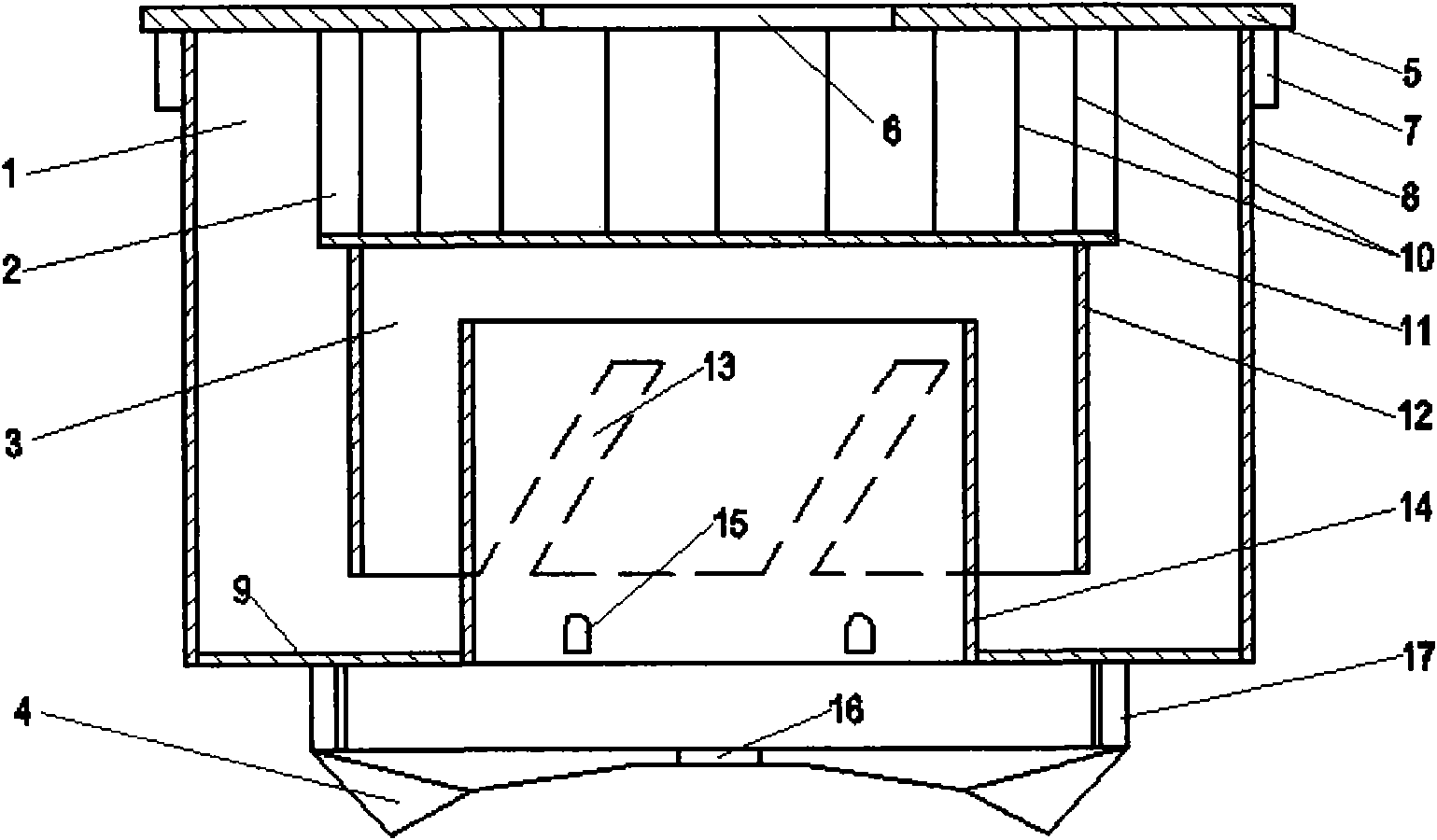

[0055] Example 2 illustrates the distribution effect of the gas-liquid flow mixing and dispersing equipment provided by the present invention.

[0056] The gas-liquid flow mixing and dispersing equipment structure provided by the invention is as follows: figure 2 shown. With water and air as the simulated medium, it is carried out in a cold mold test device with a diameter of 1000mm. The metered air and oxygen-enriched water gas-liquid two-phase are pre-distributed and mixed, and then flow into the gas-liquid flow mixing and dispersing equipment for fluid distribution. A three-dimensional synchronous multi-point liquid measuring device is used below the gas-liquid flow mixing and dispersing equipment. The distribution curve of the liquid volume along the measuring point is obtained by liquid phase sampling and metering, and the liquid phase distribution curve is drawn. The results are shown in Figure 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com