Composite material closed boxcar

A composite material and truck technology, which is applied in the field of composite material enclosed truck compartments, can solve the problems of ignoring the thermal insulation, heat insulation and antifreeze capabilities of the interior environment, the decrease in the strength or anti-collision ability of the compartment, and the ignoring of the anti-vibration and anti-noise capabilities of the compartment. Achieve the effect of good thermal insulation effect, low production cost and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

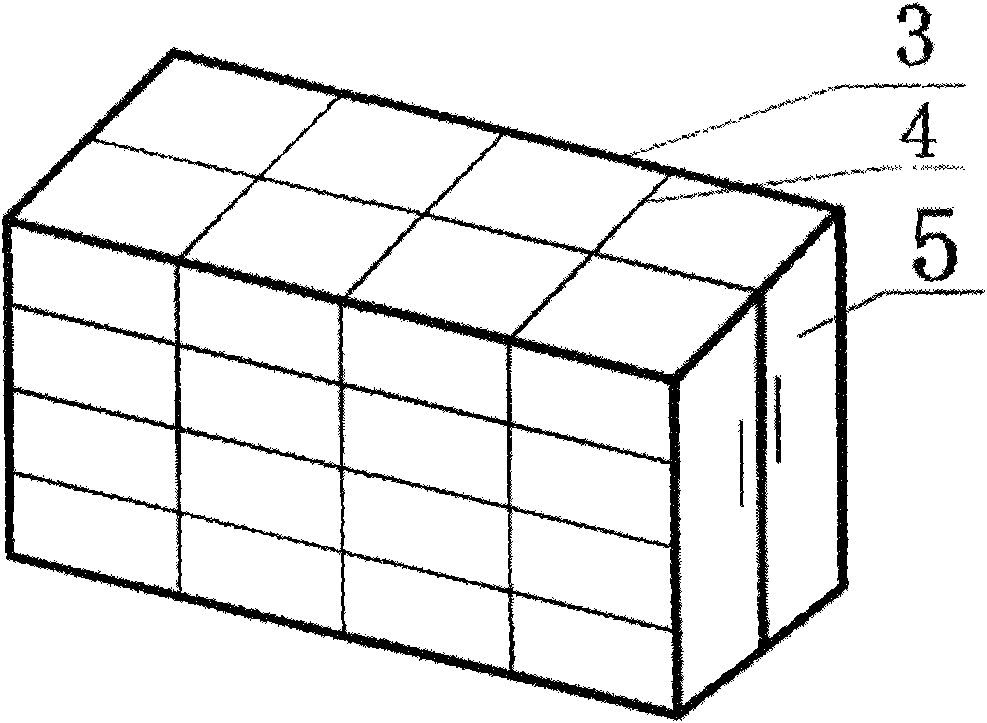

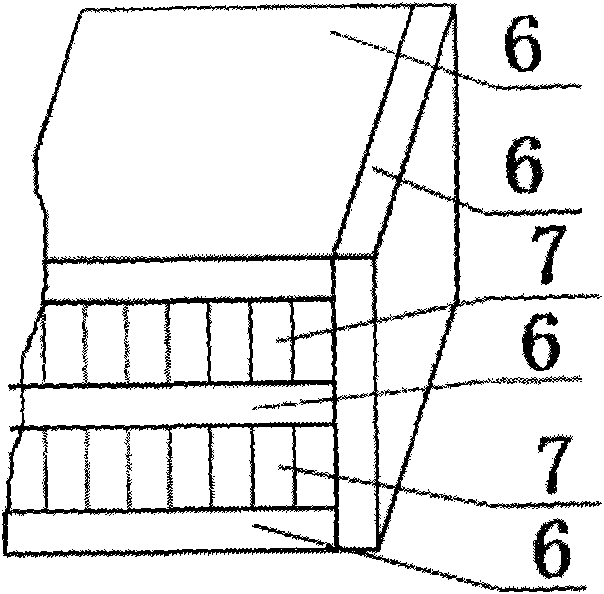

[0019] A composite material enclosed freight car, its structure is composed of an outer layer, a middle layer and an inner layer. The outer layer is composed of a gel coat layer and a structural layer, the middle layer is composed of a metal frame and a laminated glass steel plate, and the inner layer is a structural layer. The gel coat layer is neopentyl glycol-o-phthalic or neopentyl glycol-isophthalic resin;

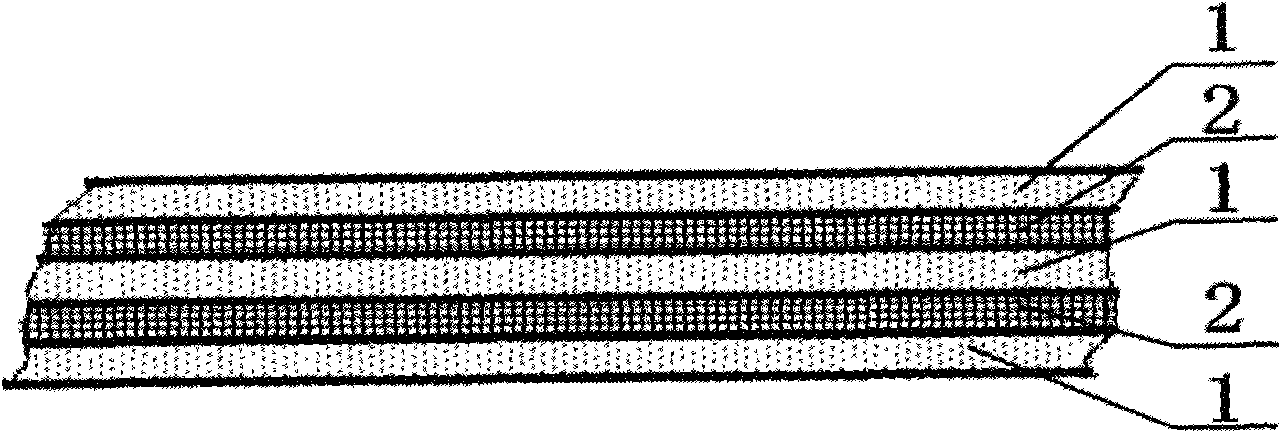

[0020] The structure layer is 5 layers (see figure 1 ), namely resin layer 1, fiber layer 2, resin layer 1, fiber layer 2, resin layer 1; the formula of resin layer 1 is 196 resin 100 grams, curing agent methyl ethyl ketone peroxide 3 grams, accelerator cobalt naphthenate 3 grams ; The fiber layer 2 is fiberglass cloth.

[0021] The layers are connected by glue. The glue uses polyester resin as the main material. The formula is 100 grams of 711 unsaturated polyester resin, 3 grams of initiator cyclohexanone peroxide paste, and 2 grams of styrene solution of accelerator co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com