Polymer composite material with oriented padding and preparation method thereof

A composite material and polymer technology, applied in the field of polymer composite materials and its preparation, can solve the problems of cumbersome process, time-consuming, difficult large-scale production, etc., and achieve the effect of simple equipment, common raw materials, and outstanding substantive characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

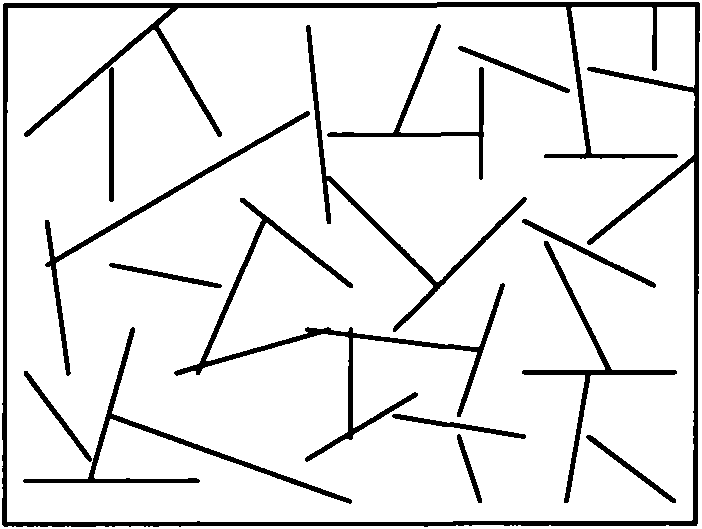

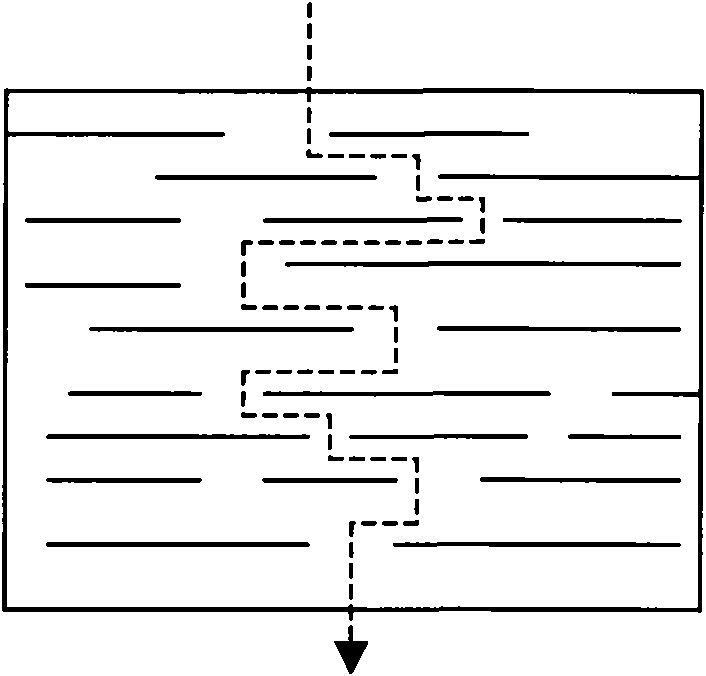

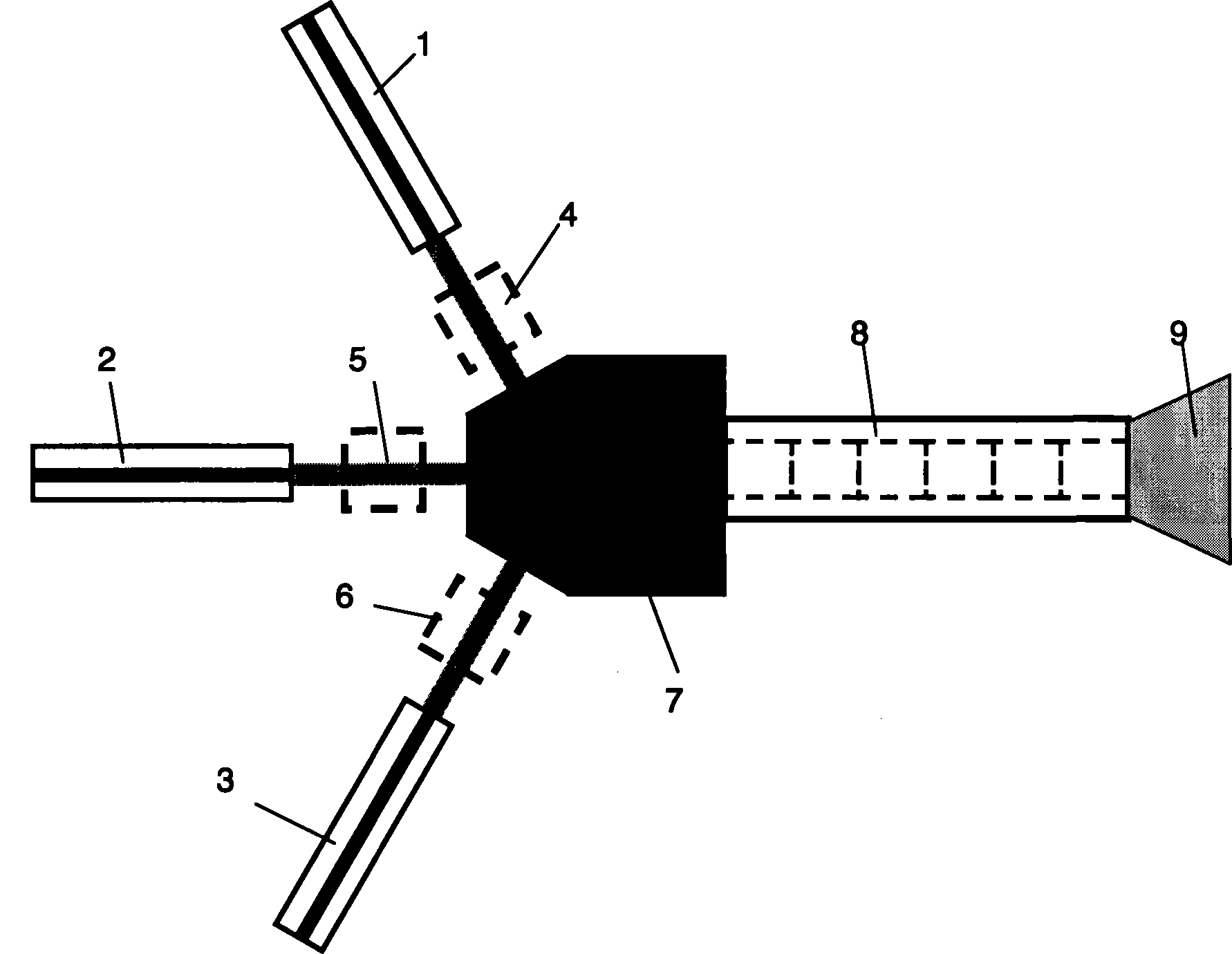

[0045] The polymer composite material with oriented fillers comprises a polymer matrix filled with a shape anisotropic filler. In this embodiment, the polymer matrix is polyvinyl alcohol (PVA) with a molecular weight of about 7000, and the filler is Na-type montmorillonite. A material composed of polyvinyl alcohol (PVA) and Na-type montmorillonite is prepared into a composite material by a layer doubling extrusion method of division-re-lamination and confluence, and the shape-anisotropic filler is oriented in the material stream during the preparation.

[0046] The preparation method of the polymer composite material with orientation filler, it comprises:

[0047] Preparatory steps: first put an appropriate amount of montmorillonite powder into deionized water, then vigorously stir for a period of time (for example, two weeks), then stand still, and then collect the supernatant after standing. Slowly add PVA into deionized water at 80°C and dissolve under vigorous stirring ...

Embodiment 2

[0051] The polymer composite material with oriented filler adopts a binary structure, that is, two strands of different materials are laminated and then extruded. It includes two polymer matrices, the first polymer matrix is filled with a shape anisotropic filler. In this embodiment, the first polymer matrix is polycarbonate (PC), and the second polymer matrix is polyethylene terephthalate (PET). Both PC and PET are commercially available products . The polycarbonate (PC) is filled with a filler, the filler is talc, the average thickness of the talc particles is about 2 microns, the aspect ratio is about 10, that is, the average diameter is about 20 microns. The above-mentioned polycarbonate (PC) and talc constitute the material composition A, and the PET constitutes the material composition B. These material compositions are prepared into a composite material by layer multiplication extrusion method of lamination-division-re-lamination and confluence, during which the...

Embodiment 3

[0056] The polymer composite material with oriented fillers comprises a polymer matrix filled with a shape anisotropic filler. In this embodiment, the polymer matrix is nylon 6, the filler is organic montmorillonite, and the organic montmorillonite is clay modified by intercalation of 12-amino-12-acid. Composites consisting of nylon 6 and organomontmorillonite were produced by split-relamination confluent layer doubling extrusion in which the shape-anisotropic filler was oriented in the material stream.

[0057] The preparation method of the polymer composite material with orientation filler, it comprises:

[0058] Preliminary steps: first mix caprolactam with organic montmorillonite, then use in-situ wet polymerization to prepare the exfoliated clay-filled nylon 6 nanocomposite material containing 5wt% (montmorillonite is almost completely exfoliated in the nylon 6 matrix), pulverize composite material.

[0059] Layer multiplication step: use a twin-screw extruder to furt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com