Impressing hard template in nanostructure

A nanostructure and hard template technology, applied in optics, optomechanical equipment, instruments, etc., can solve the problems of high cost, long preparation cycle of nanoscale imprint template, cost constraints of nanoimprint, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. First, deposit a layer of titanium with a thickness of 1 μm on the surface of 1 mm thick 2 inch quartz glass by sputtering.

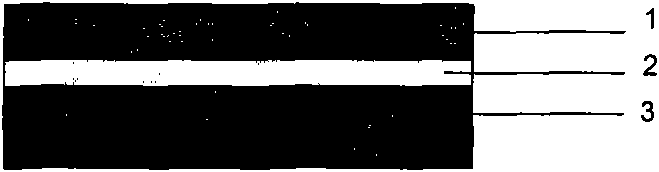

[0024] 2. Next, cover a layer of aluminum on the surface of the titanium layer by evaporation, with a thickness of 10 μm. Made into a hard material base ( figure 1 ).

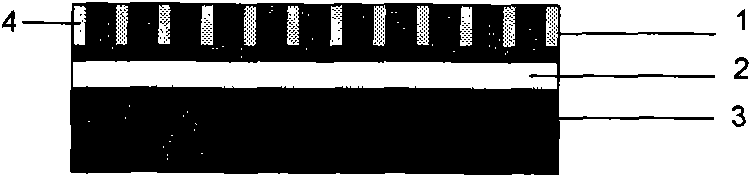

[0025] 3. Using the hard material substrate as the anode, the porous template ( figure 2 ), control the anodic oxidation reaction to terminate at the aluminum / titanium interface, soak in 5% (volume fraction) phosphoric acid to remove the barrier layer, and then use RIE to etch under the conditions of CF4 (15sccm) / AR (75sccm) mixed gas and power 210W 100s, remove the titanium layer at the bottom of the alumina hole.

[0026] 4. Carry out modification treatment by vapor deposition method, the modifier is CF3-(CF2)7-(CH2)2-SiCl3.

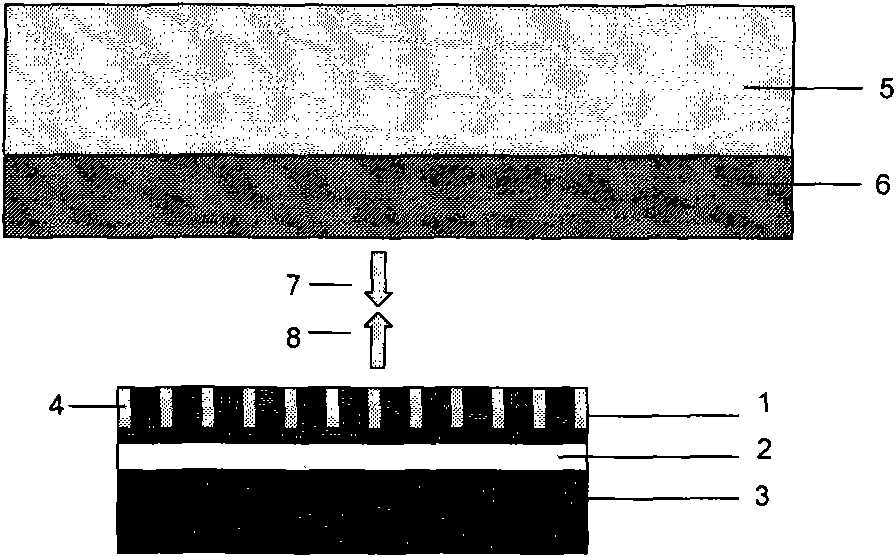

[0027] 5. The nanoscale high-density array structure was replicated on the surface of the silicon substrate by the cold imprinting process ( ima...

Embodiment 2

[0029] 1. First, a layer of chromium is deposited by sputtering on the surface of 0.5 mm thick 2-inch quartz glass, with a thickness of 2 μm.

[0030] 2. Then cover a layer of aluminum on the surface of the chromium layer by evaporation method, with a thickness of 100 μm. Made into a hard material base ( figure 1 ).

[0031] 3. Using the hard material substrate as the anode, the porous template ( figure 2 ), the thickness of the aluminum layer left at the bottom of the alumina hole is controlled at 10 μm.

[0032] 4. Use low-pressure spraying method for modification treatment to form a layer of modification film to reduce its surface energy. The modifier is CF3-(CF2)7-(CH2)2-SiCl3.

[0033] 5. Replicate a high-density structure on the surface of the silicon substrate using a hot embossing process ( image 3 , Figure 4 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com