Positive type infrared light sensitive composition and positive heat-sensitive lithographic plate

A composition, infrared light technology, applied in printing plate preparation, photosensitive materials for opto-mechanical equipment, printing, etc., can solve the problems of poor thermal stability, poor sensitivity stability of plate materials, etc. Shortened thermal stability time and stable sensitivity performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Preparation of polymer infrared dye:

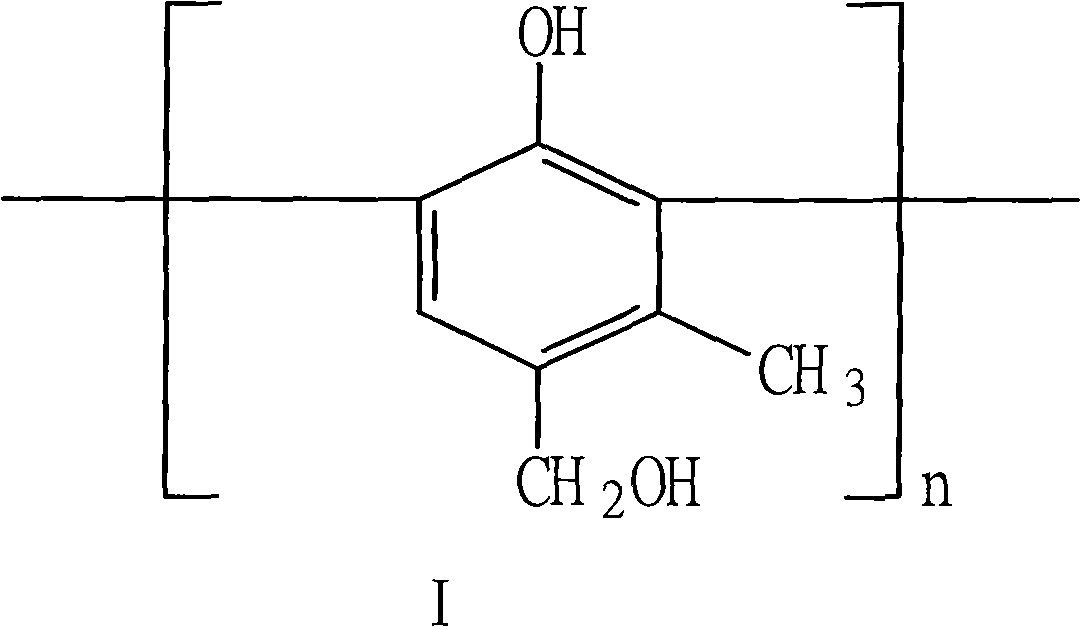

[0044] The alkali-soluble resin used in the preparation of the polymer infrared dye is the methylolation product R-32 of the m-cresol aldehyde resin produced by the second film factory of the Lucky Group shown in the structural formula II, and the molecular weight is between 8,000 and 10,000.

[0045] 100g of methylol phenolic resin R-32 was dissolved in 400ml of N,N-dimethylformamide to make a solution. At 40°C, 0.2 g of sodium halide was slowly added to the solution. The reaction was stirred for 30 minutes. Dissolve 20 g of 2-[2-[2-chloro-3-[2-(1,3-dihydro-1,1,3-trimethyl-2H- Phenylindole-2-ylidene)-acetal]-1-cyclopenten-1-yl]-ethylene]-1,1,3-trimethyl-1H-phenylindole tetramethylbenzenesulfonate Salt solution, slowly added to the solution containing R-32 resin. The reaction was carried out for 10 hours. The solution was then cooled at room temperature and the product was isolated by settling in water. The product was co...

Embodiment 2

[0053] (1) Preparation of polymer infrared dye:

[0054] The alkali-soluble resin used in the preparation of the polymer infrared dye is the methylolation product RM-1 of the m-cresol aldehyde resin produced by the second film factory of the Lucky Group shown in the structural formula II.

[0055] 100g of methylol phenolic resin RM-1 was dissolved in 400ml of N,N-dimethylformamide to make a solution. At 40°C, 0.2 g of sodium halide was slowly added to the solution. The reaction was stirred for 30 minutes. Dissolve 20 g of 2-[2-[2-chloro-3-[2-(1,3-dihydro-1,1,3-trimethyl-2H- Phenylindole-2-ylidene)-acetal]-1-cyclopenten-1-yl]-ethylene]-1,1,3-trimethyl-1H-phenylindole tetramethylbenzenesulfonate Acid solution, slowly added to the solution containing RM-1 resin. The reaction was carried out for 10 hours. The solution was then cooled at room temperature and the product was isolated by settling in water. The product was collected by vacuum filtration, rinsed with water and ai...

Embodiment 3

[0063] (1) Preparation of polymer infrared dye:

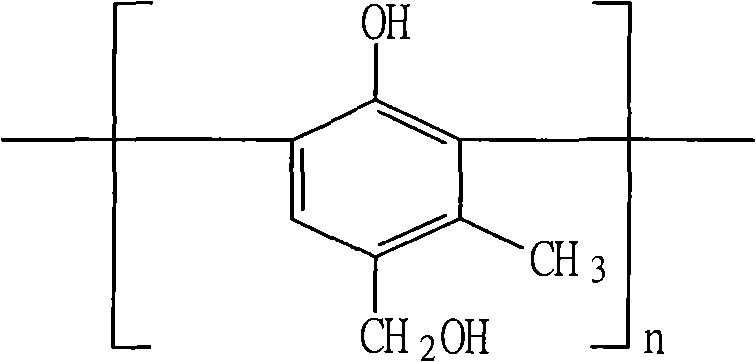

[0064] The alkali-soluble resin used in the preparation of the polymer infrared dye is the methylolation product BTB-29 of the m-cresol aldehyde resin produced by Weihai Tiancheng Chemical Industry shown in structural formula I.

[0065] 100g of methylol phenolic resin BTB-29 was dissolved in 400ml of N,N-dimethylformamide to make a solution. At 40°C, 0.2 g of sodium halide was slowly added to the solution. The reaction was stirred for 30 minutes. Dissolve 20 g of 2-[2-[2-chloro-3-[2-(1,3-dihydro-1,1,3-trimethyl-2H- Phenylindole-2-ylidene)-acetal]-1-cyclopenten-1-yl]-ethylene]-1,1,3-trimethyl-1H-phenylindole tetramethylbenzenesulfonate Add salt solution slowly to the solution containing BTB-29 resin. The reaction was carried out for 10 hours. The solution was then cooled at room temperature and the product was isolated by settling in water. The product was collected by vacuum filtration, rinsed with water and air dried. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com