Nanosecond pulse optical fiber laser and control method thereof

A fiber laser and nanosecond pulse technology, applied in the field of lasers, can solve the problems of uneven pulse, low pulse peak power, high noise, etc., and achieve the effect of suppressing ASE background noise, improving service life, and flat waveform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

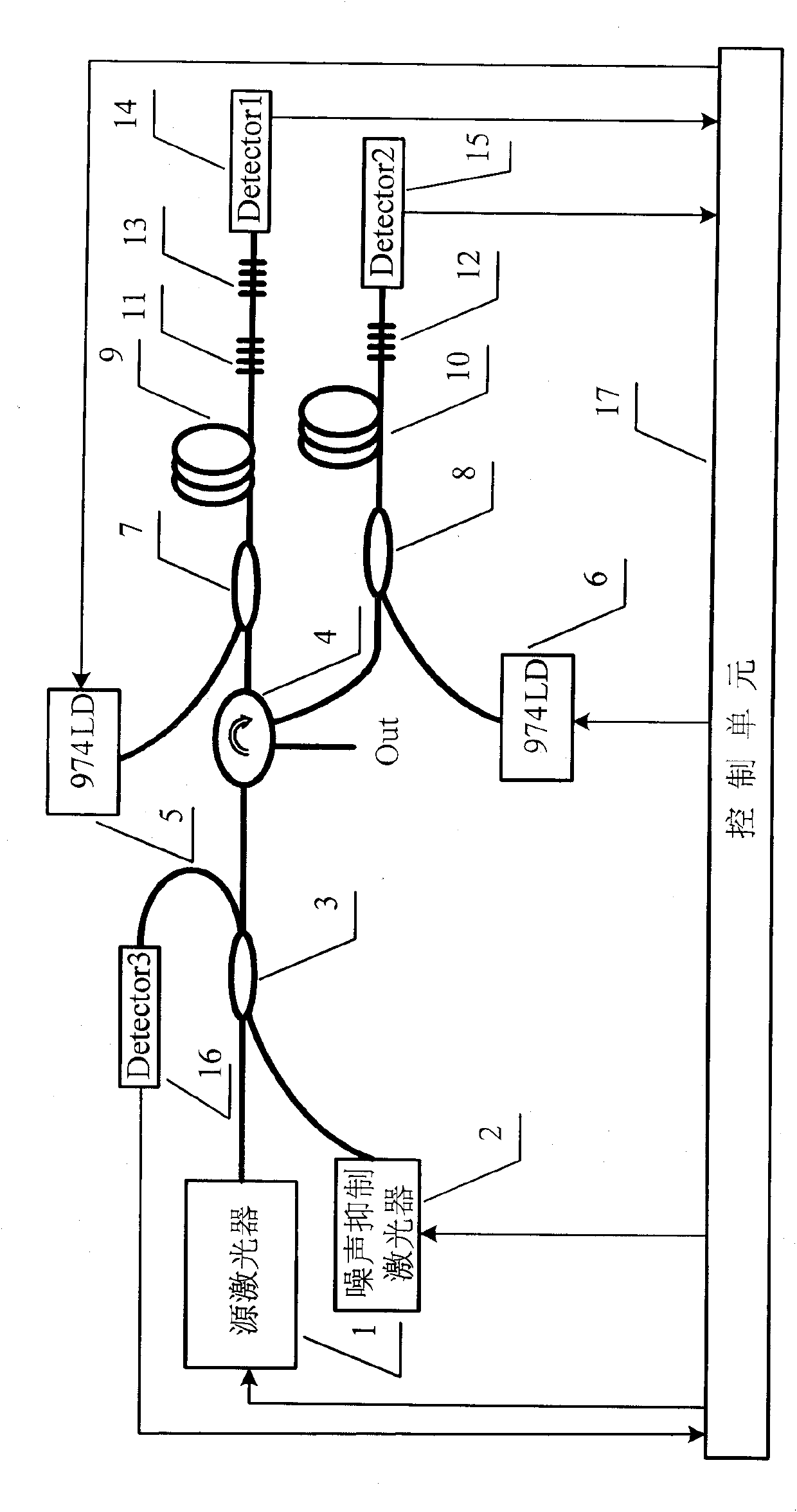

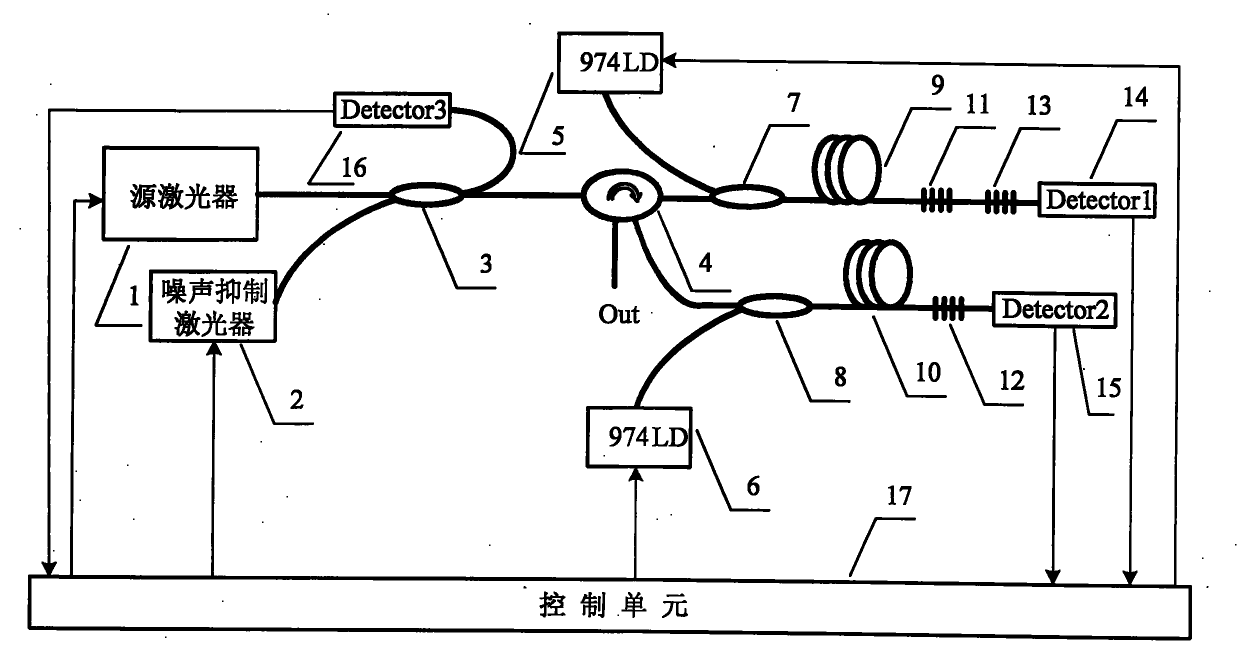

[0023] Such as figure 1 As shown, the nanosecond pulsed fiber laser of this embodiment includes a control unit 17, a source laser 1, a noise suppression laser 2, a fiber coupler 3, a first wavelength division multiplexer 7, a second wavelength division multiplexer 8, a second wavelength division multiplexer 8, a A pump laser diode 5, a second pump laser diode 6, a first doped fiber 9, a second doped fiber 10, a first fiber grating 11, a second fiber grating 12, and a third fiber grating 13 , the first photodetector 14, the second photodetector 15, the third photodetector 16 and the four-port optical fiber circulator 4; the four-port optical fiber circulator 4 has an input port, an output port, a second port, and a third port; The laser center wavelength of the source laser 1 is in the reflection band of the first fiber grating 11 and the second fiber grating 12, and the laser center wavelength of the noise suppression laser 2 is in the reflection band of the third fiber gratin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com