MEMS atom cavity chip and preparation method thereof

An atomic cavity and chip technology, which is applied in the field of integrated atomic cavity chips and its preparation, can solve the problems of low integration, complex processing technology of thermally isolated atomic cavity, etc., and achieve the effects of improved isolation effect, shortened heating time, and high integration degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

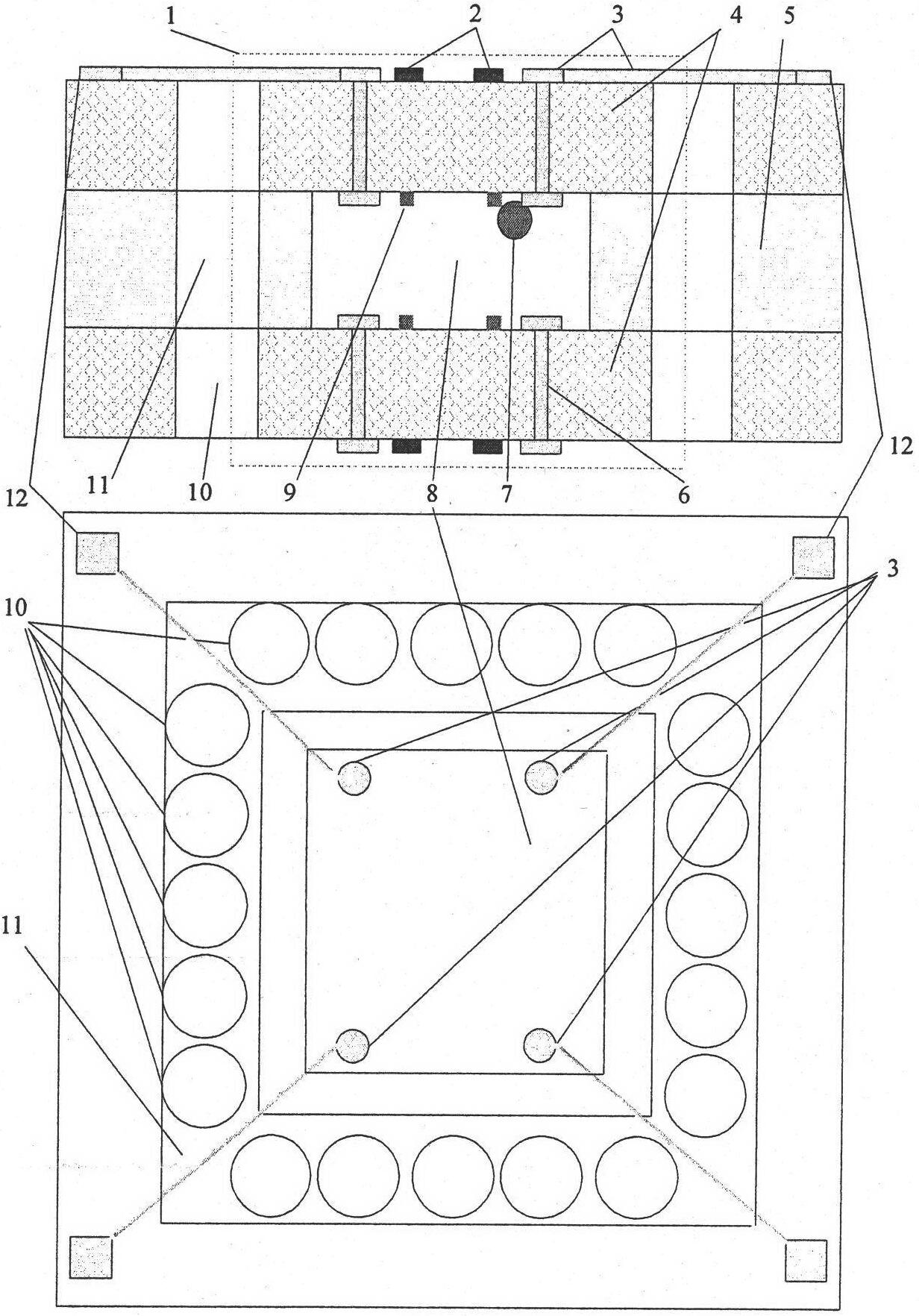

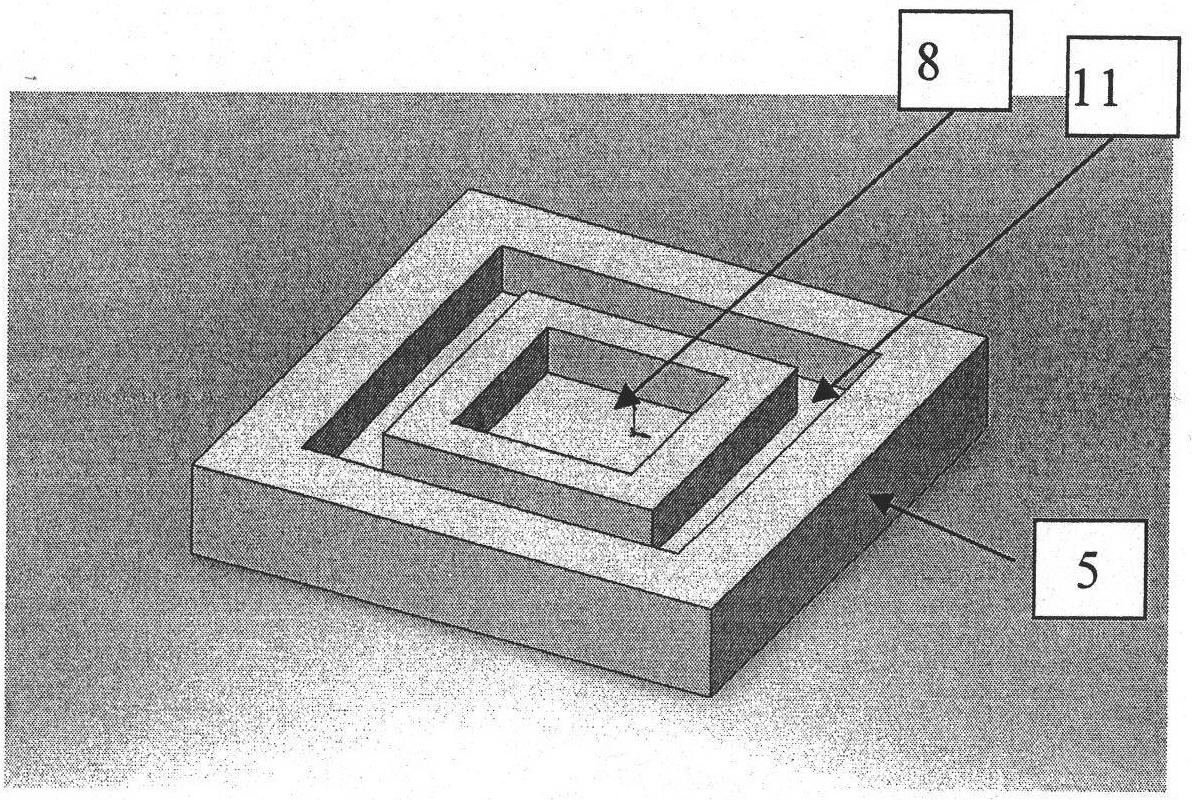

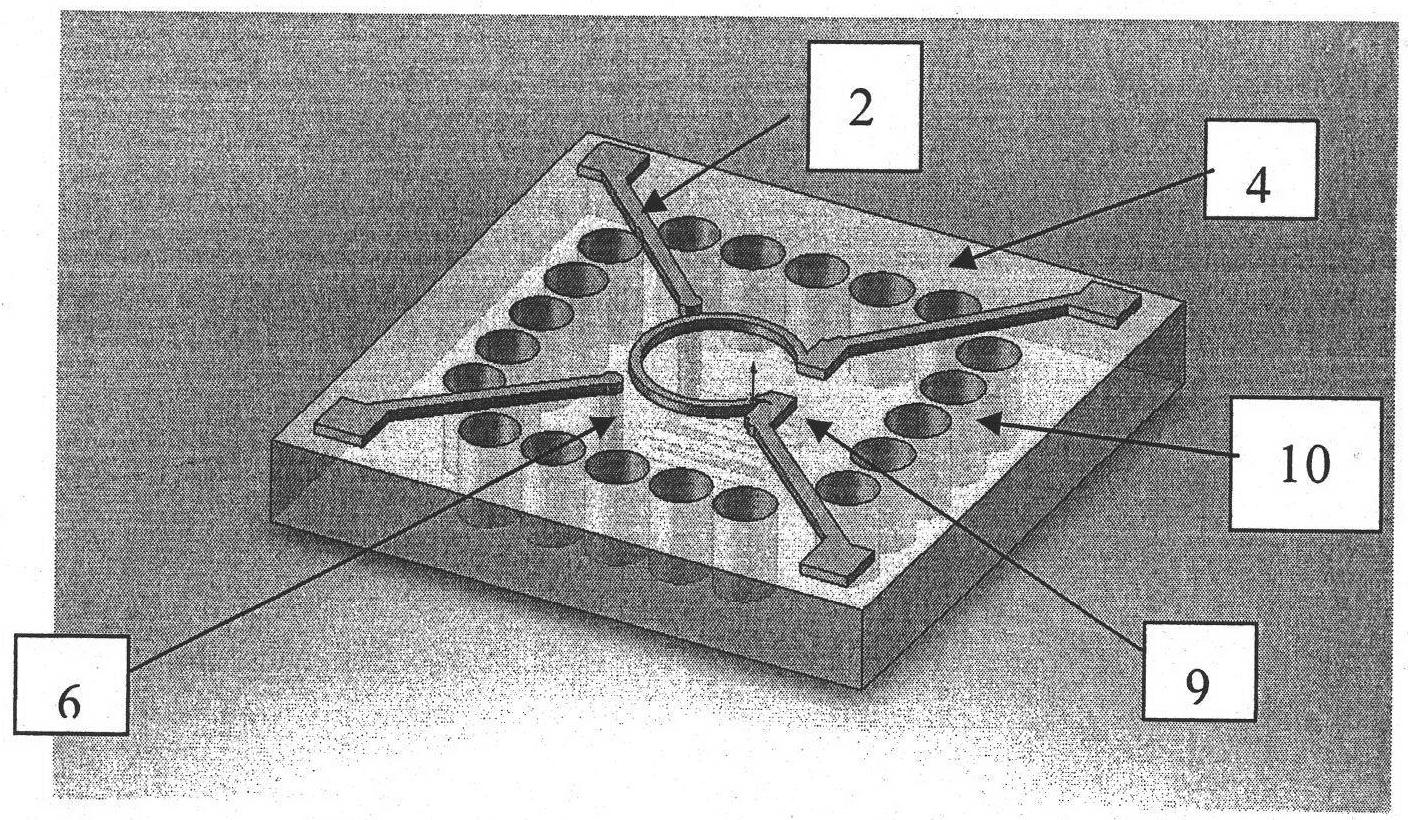

[0038] like figure 1 As shown, it is a structural schematic diagram of the MEMS atomic cavity chip of the present invention, including a radio frequency coil 2, an electrical connection lead 3, two glass substrates 4, a silicon substrate 5, an electrical connection through hole 6, an alkali metal 7, and a cavity space 8. Resistance heating wire 9, thermal isolation through hole 10, thermal isolation ring 11, pad 12, two glass substrates 4 and one silicon substrate 5 are bonded together to form a thermal isolation atomic cavity 1, namely figure 1 The box part indicated in is thermally isolated atomic cavity 1;

[0039] The two glass substrates 4 are identical in structure and symmetrical up and down. There are thermal isolation through holes 10 and electrical connection through holes 6 on the glass substrate 4. The electrical connection through holes 6 are filled with metal nickel, or other electroplatable metals. , such as copper, silver, etc. There are Cr / Au radio frequency...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com