Epoxy modified silicon-contained waterborne acrylic resin and coating thereof

A technology of acrylic resin and epoxy modification, applied in the direction of coating, etc., can solve the problems of unfavorable wide application, unfavorable production, high temperature curing, etc., and achieve the effects of easy operation, enhanced retention and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Preparation of epoxy-modified silicon-containing water-based acrylic resin

[0030] a. Synthesis of epoxy resin monoacrylate:

[0031] Feed epoxy resin (E-44) and acrylic acid in a molar ratio of 1:1, add 5‰ hydroquinone as a polymerization inhibitor, react at 100°C for 2 hours, and discharge the acid value less than 5mgKOH / g to obtain epoxy resin monoacrylate.

[0032] b. Synthesis of epoxy-modified waterborne acrylic resin:

[0033] In a 1000mL four-necked flask equipped with a thermometer, a stirrer, a condenser and a dropping funnel, add 50g each of ethanol and butyl glycol ether, mix well, replace the air in the flask with nitrogen, and mix 80gMMA, 50gBA, 60.0 A mixture of gMAA, 9.0g HEMA, 125g epoxy resin monoacrylate, 20g vinyltriethoxysilane and 1.2g azobisisobutyronitrile was put into the dropping funnel, and the contents in the flask were kept at 80-90°C for 3h After dripping, keep it warm at this temperature for 1 hour, then drop 0.5g of azobisis...

Embodiment 2

[0034]Example 2 Preparation of epoxy-modified silicon-containing water-based acrylic resin

[0035] The synthesis method of epoxy resin monoacrylate is the same as in Example 1, using epoxy resins E-51 and E-20 as reactants. The synthesis of epoxy-modified water-based acrylic resin is also carried out with reference to the method of Example 1, but the vinyltriethoxysilane monomer therein is adjusted to methylvinyldichlorosilane 10g, vinyltrichlorosilane 15g, and the obtained The solid content of the resin is 55%-60%.

Embodiment 3

[0036] Example 3 Preparation of epoxy-modified silicon-containing water-based acrylic water-based coating

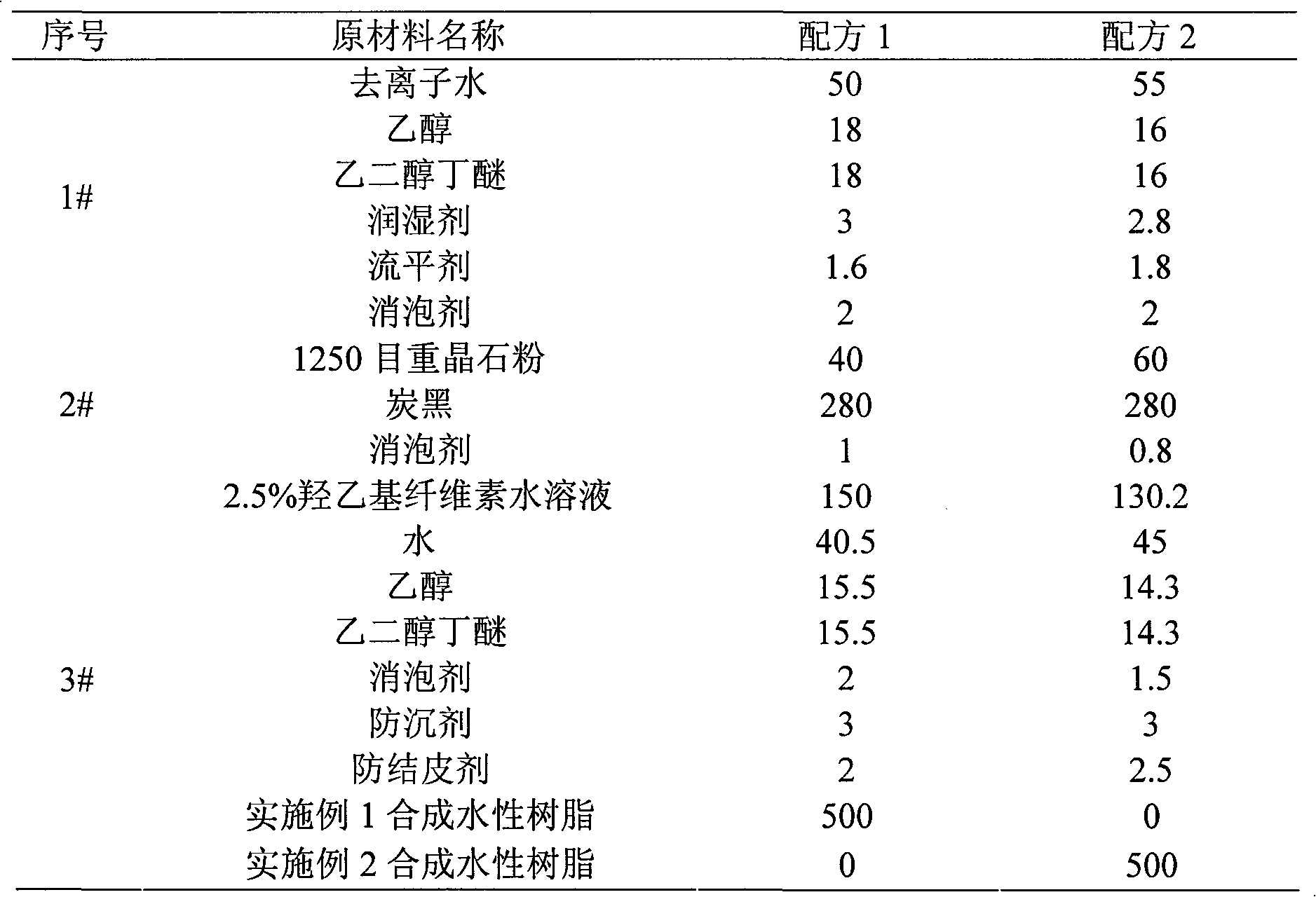

[0037] Feed according to the order of 1#, 2# and 3# listed in Table 1, that is, after mixing the raw materials in 1# evenly, add 2# component, disperse evenly at a high speed, then add 3# component, sand mill until the fineness reaches Below 25μm, it can be discharged. The solid content of the prepared water-based paint is about 49-55%, and the viscosity is 80-100KU (Stormer viscosity).

[0038] Table 1 Raw materials for water-based coatings (both parts by weight)

[0039]

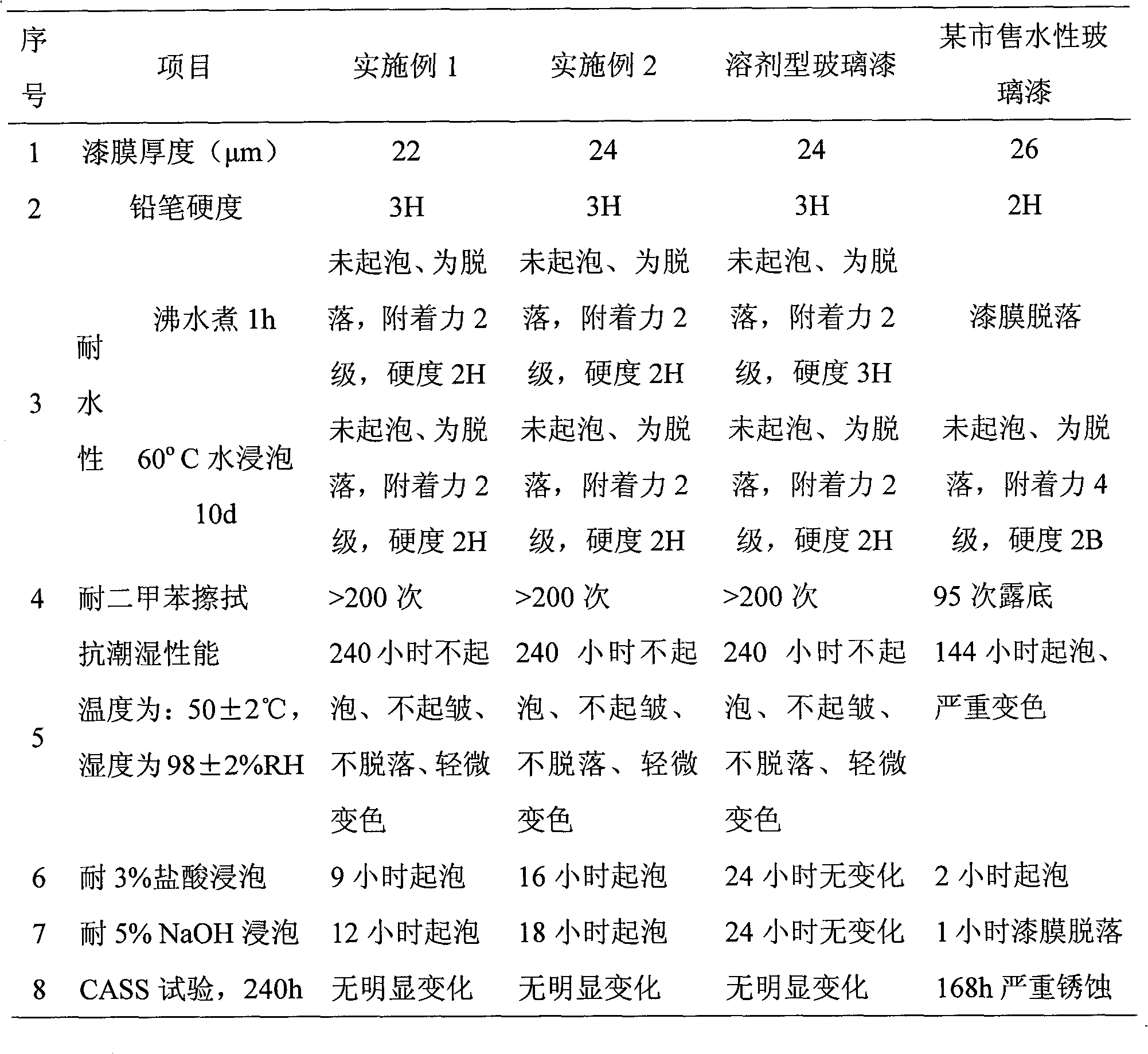

[0040] The water-based coating was diluted with deionized water to a viscosity suitable for spraying, sprayed onto a glass substrate, and baked at 80°C for 20 minutes. The performance of the coating film was tested as shown in Table 2.

[0041] According to the comparison of the test results in Table 2 with our company's solvent-based glass paint and a certain commercially available water-based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com