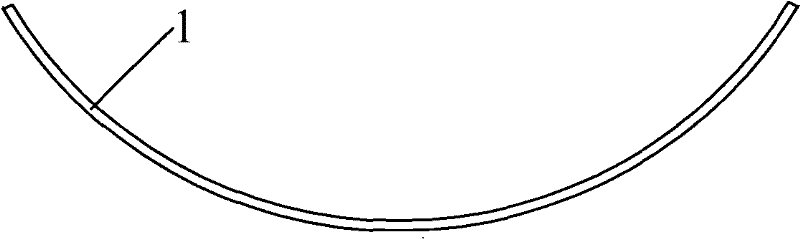

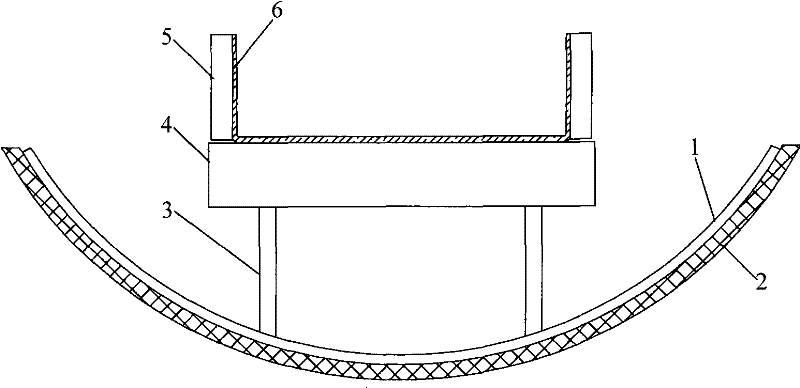

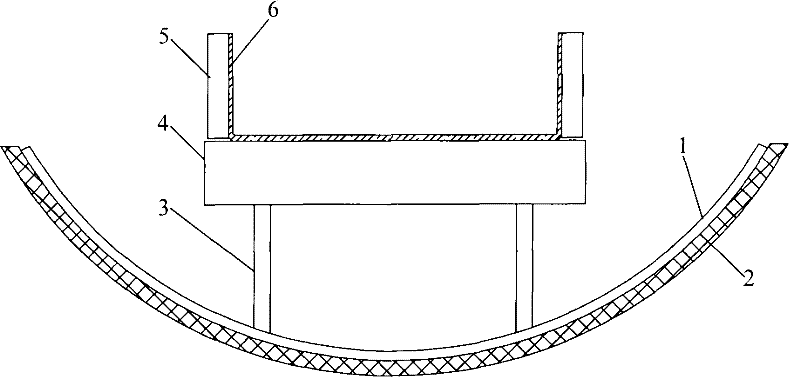

Lining for polysilicon crystal oven wall protection and manufacturing method thereof

A manufacturing method and technology of polysilicon, which are applied in the growth of polycrystalline materials, chemical instruments and methods, furnaces, etc., can solve problems such as threats to the life safety of operators, economic losses, and influences, and achieve damage avoidance, excellent thermal shock resistance, and thermal shock resistance. Significant economic and social effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] First, 45 parts of massive high-purity quartz and 55 parts of powdered high-purity quartz are put into granulation equipment for wet granulation, and after adding water and grinding, the particle size is controlled at 85 μm to 95 μm; after the slurry is taken out, it is fully stirred, and placed After 48 hours, the physical and chemical indicators will be tested, and the next process can be carried out after passing the test; the slurry is poured into the pressure device, and the slurry is injected into the plaster mold with 2 bar pressure. The distribution is uniform, the vibration frequency is 30-40 times / min, and the amplitude is 2-3 mm; put it in the mold for 5 hours, make it fully dehydrated, and then demould, the demoulding must be very careful; put it in the dryer after demoulding Drying in the furnace, the drying temperature is 180°C, and it has a certain strength after drying; put the dried body into the kiln for sintering, and use a reducing atmosphere to prote...

Embodiment 2

[0036] First, put 48 parts of massive high-purity quartz and 52 parts of powdered high-purity quartz into the granulation equipment for wet granulation. The geometric size of the block material is less than 50 mm, and the particle diameter of the powder material is less than 5 mm. Add water After grinding, the particle size is controlled at 80 μm to 120 μm; the slurry is taken out and fully stirred, and the physical and chemical indicators are tested after being placed for 30 hours. Inject the slurry into the gypsum mold with a pressure of 2.5bar. The grouting in the early stage is supplemented by slight vibration to make the material evenly distributed. The vibration frequency is 30-35 times / min, and the amplitude is 1-3mm; After it is fully dehydrated, it will be demoulded, and the demoulding must be very careful; after demoulding, put it in a dryer for drying, the drying temperature is 210 ° C, and it has a certain strength after drying; put the dried embryo body into the ki...

Embodiment 3

[0039] First, put 50 parts of massive high-purity quartz and 50 parts of powdered high-purity quartz into the granulation equipment for wet granulation. The geometric size of the block material is less than 50 mm, and the particle diameter of the powder material is less than 5 mm. Add water After grinding, the particle size should be controlled at 90 μm to 110 μm; after taking out the slurry, fully stir it, place it for 36 hours, pour it into the pressure device, and inject the slurry into the plaster mold with a pressure of 3 bar. The frequency is 35-40 times per minute, and the amplitude is 1-3mm; put it in the mold for 8 hours, make it fully dehydrated, and then demould; after demoulding, put it in a dryer for drying, and the drying temperature is 185°C; Put the dried body into a kiln for sintering. During the sintering process, a reducing atmosphere is used for protection. The sintering temperature is 950°C to 1450°C, and the sintering time is 50 hours to obtain an opaque q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com