Nitrogen closed cycle drying and solvent recovery system

A closed-circuit circulation and recovery system technology, applied in the direction of drying solid materials, drying gas arrangement, heating to dry solid materials, etc., can solve the problem of limited solvent collection, etc., and achieve environmental protection, stable air pressure, and good fluidized drying effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

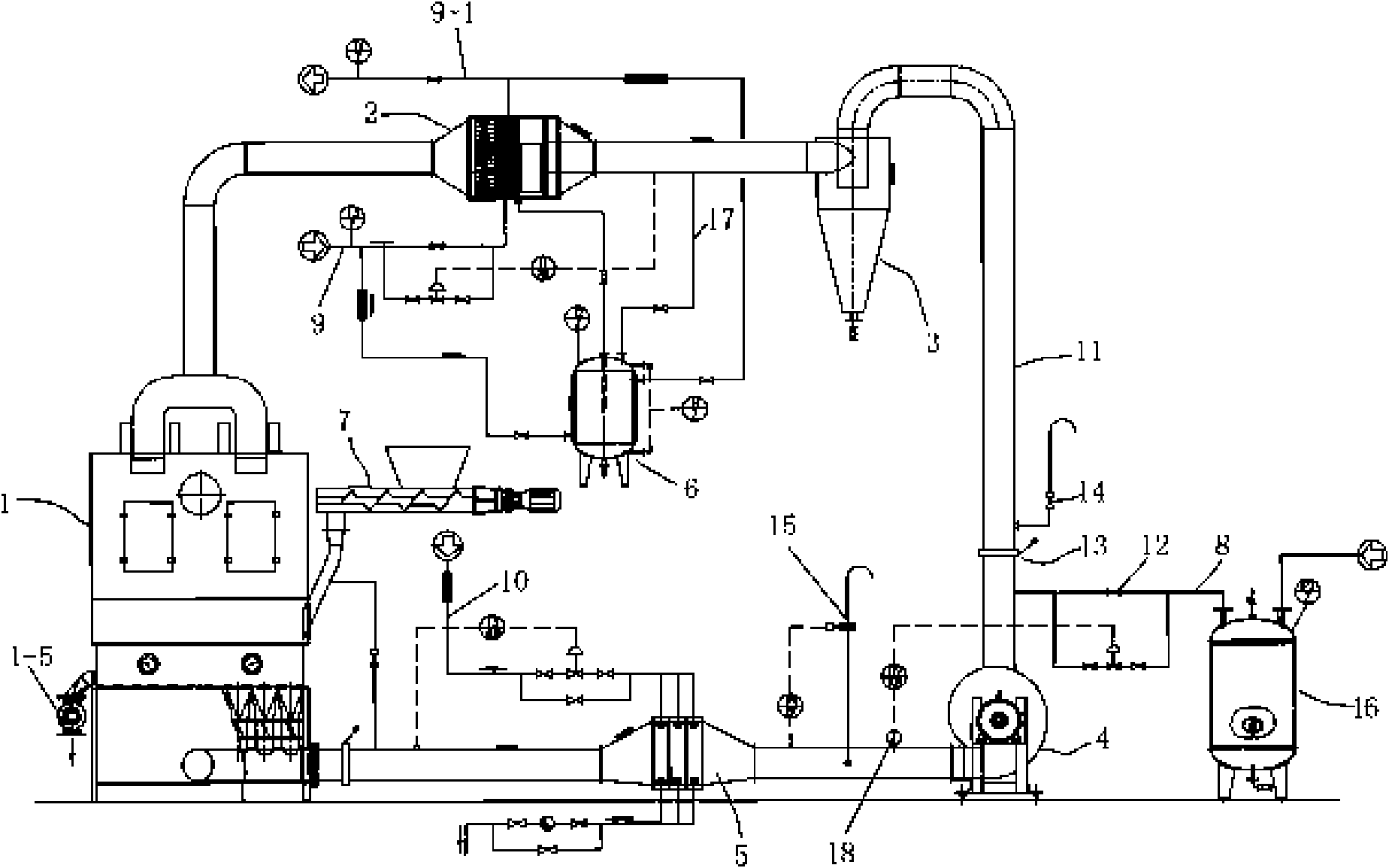

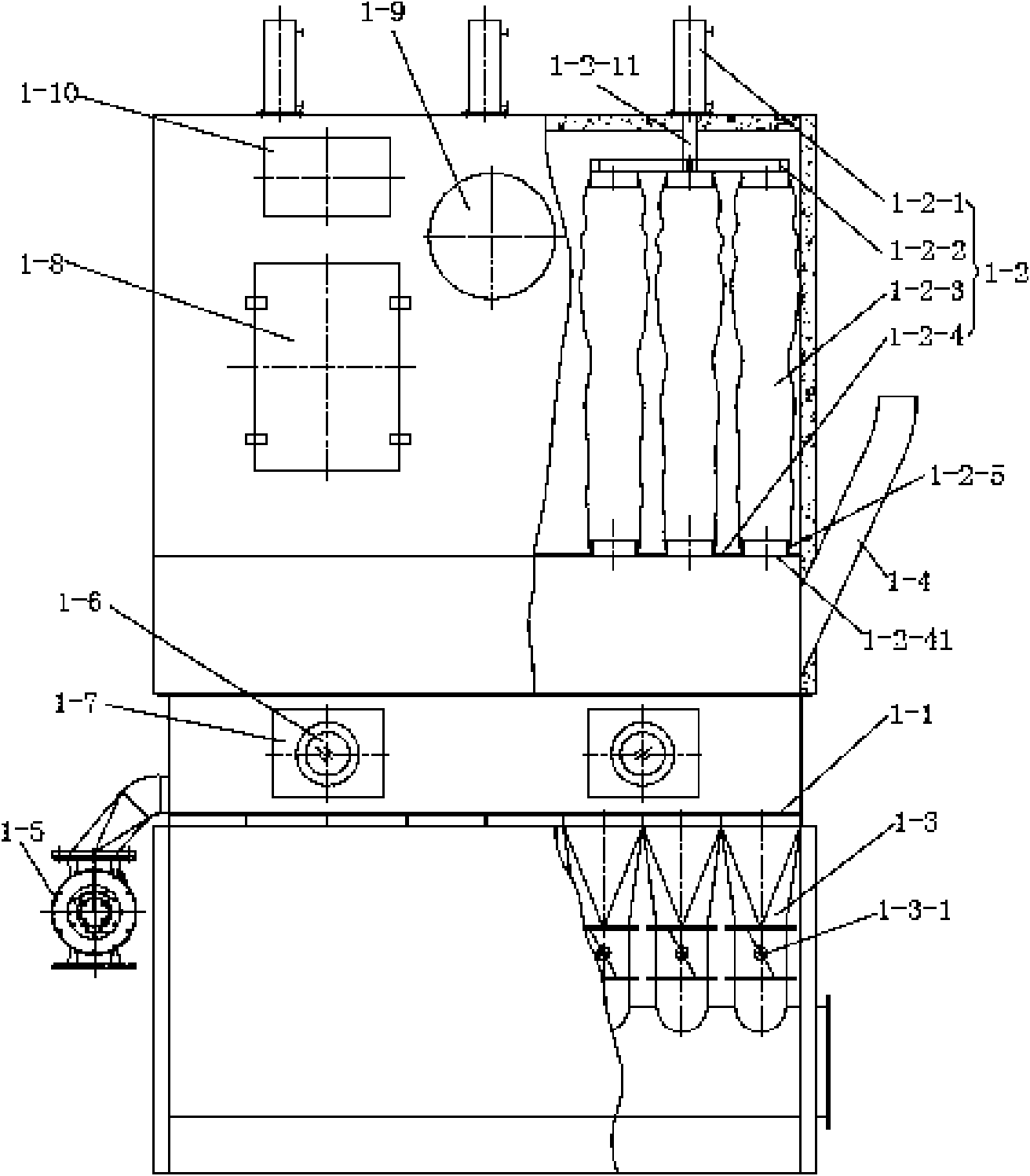

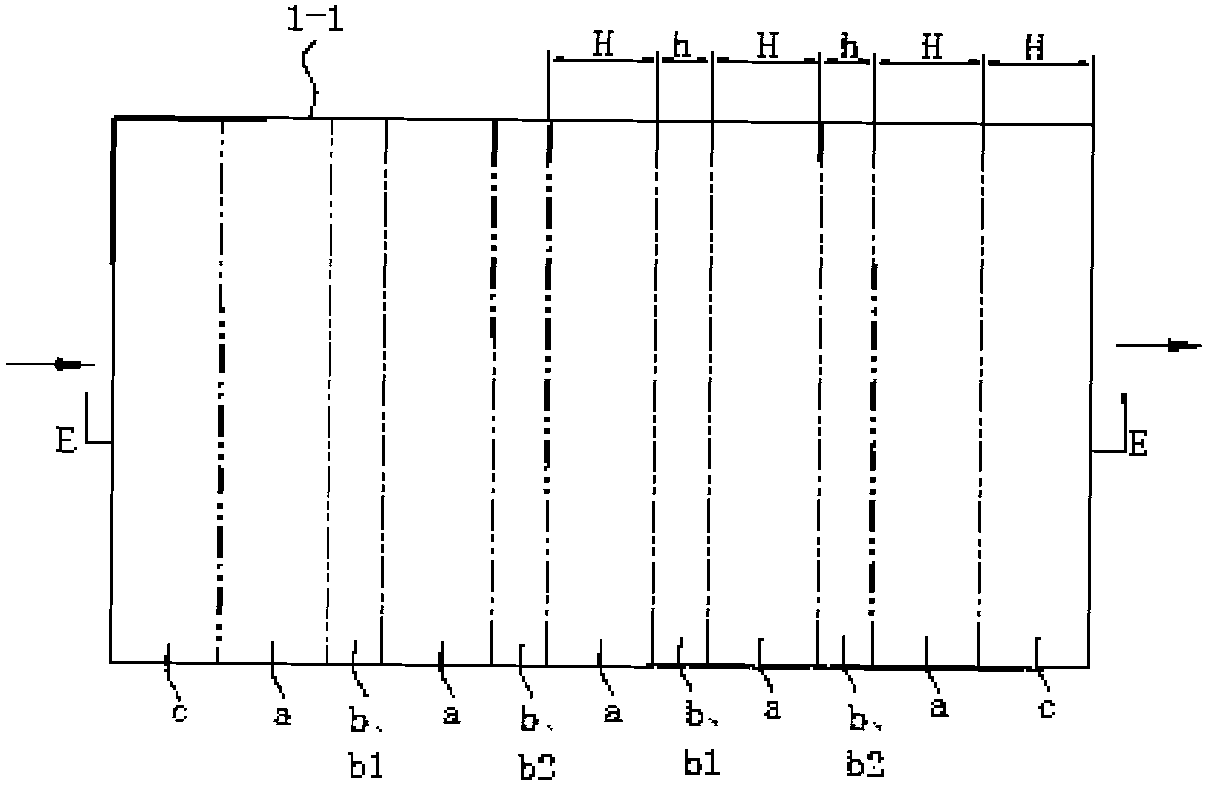

[0040] figure 1 As shown, this embodiment has a fluidized bed dryer 1, a condensing device 2, a solid-gas separator 3, a circulating fan 4, a nitrogen heater 5, a solvent recovery tank 6, a material-sealed screw feeder 7, and a nitrogen supply pipe 8 , coolant supply pipe 9, steam supply pipe 10.

[0041] The air outlet of the fluidized bed dryer 1 is connected to the air inlet of the condensing device 2 through a pipeline, the air outlet of the condensing device 2 is connected to the solid-gas separator 3 through a pipeline, and the outlet of the solid-gas separator 3 The tuyere is connected with the circulation fan 4 through the circulation pipe 11, the wind output by the circulation fan 4 is sent to the nitrogen heater 5 for heating through the pipe, and the heated nitrogen is sent into the dryer 1 through the pipe. The circulation pipeline 11 connecting the solid-gas separator 3 and the circulation fan 4 is provided with a manual butterfly valve 13 and a vent port, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com