Method for preparing counter electrode of dye-sensitized solar cell

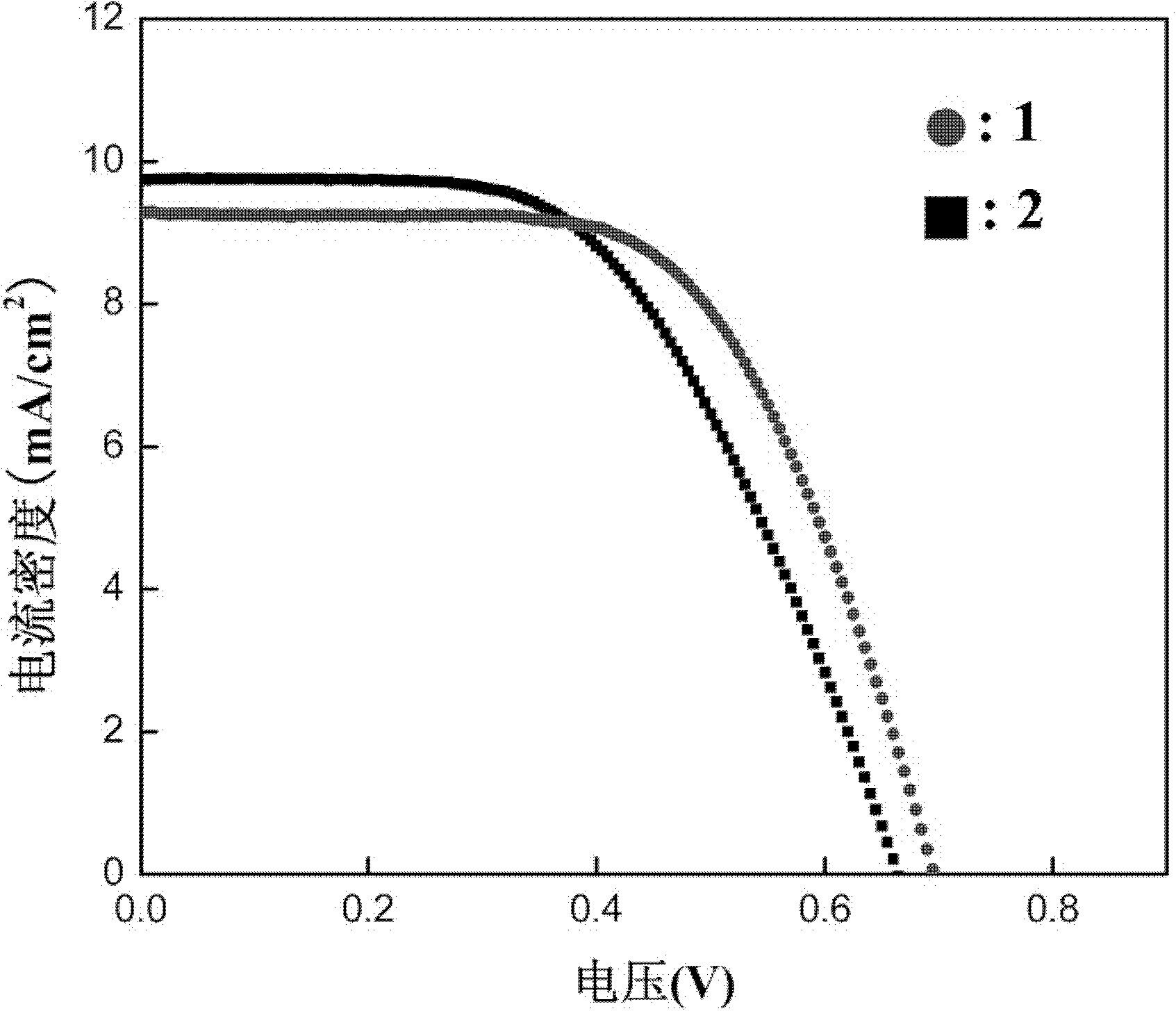

A technology of solar cells and dye sensitization, applied in the field of solar cells, can solve problems such as inability to improve cell conversion efficiency, influence of electrode resistance, uneven loading of platinum, etc., achieve low cost, increase conversion efficiency, and increase specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Step 1: Weigh 3 grams of chloroplatinic acid, slowly pour it into a volumetric flask containing 100 grams of isopropanol, ultrasonically disperse it for 15 minutes, and then stir it with a magnet for 15 minutes, until there are no solid particles, disperse evenly and seal it for storage , that is, the solution A1 is prepared and set aside;

[0019] The second step: In a water bath at 80°C, slowly pour 10 grams of ethyl cellulose into a container containing 50 grams of terpineol, and stir thoroughly until translucent white particles appear, which is the carrier B1. spare;

[0020] Step 3: Mix 10 grams of the solution A1 obtained in the first step with 20 grams of the carrier B1 obtained in the second step, heat and stir in a water bath for 15 minutes, and configure it as a screen printing platinum slurry for later use;

[0021] Step 4: Take the FTO conductive glass, and clean it sequentially with deionized water containing detergent, acetone or ethanol, then rinse it wi...

Embodiment 2

[0025] Step 1: Weigh 0.2 grams of chloroplatinic acid, and slowly pour it into a volumetric flask containing 100 grams of isopropanol, ultrasonically disperse it for 15 minutes, and then carry out magnetic stirring for 15 minutes until there are no solid particles and the dispersion is uniform Afterwards, it was sealed and stored, and the solution A2 was prepared immediately.

[0026] Step 2: Weigh 10 grams of ethyl cellulose and slowly pour it into a container containing 150 grams of terpineol, and stir it fully in a water bath at 80°C until it appears translucent without white particles, which is the carrier B2 ;

[0027] Step 3: Mix 10 grams of the solution A2 obtained in the first step with 40 grams of the carrier B2 obtained in the second step, heat and stir for 15 minutes, and configure it into a platinum slurry for screen printing;

[0028] Step 4: Take the FTO conductive glass, and clean it sequentially with deionized water containing detergent, acetone or ethanol, th...

Embodiment 3

[0032] Step 1: Weigh 1 gram of chloroplatinic acid, and slowly pour it into a volumetric flask containing 100 grams of isopropanol, ultrasonically disperse it for 15 minutes, and then stir it with a magnet for 15 minutes until there are no solid particles and the dispersion is uniform Afterwards, it was sealed and stored, and the solution A3 was prepared immediately.

[0033] Step 2: Weigh 10 grams of ethyl cellulose and slowly pour it into a container containing 100 grams of terpineol, and stir it fully in a water bath at 80°C until it appears translucent without white particles, which is the carrier B3 ;

[0034] Step 3: Mix 10 grams of the solution A3 obtained in the first step with 30 grams of the carrier B3 obtained in the second step, heat and stir for 15 minutes, and configure it into a platinum slurry for screen printing;

[0035] Step 4: Take the FTO conductive glass, and clean it with deionized water containing detergent, acetone or ethanol in sequence, rinse it wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com