Method for manufacturing back contact solar energy batteries

A technology for solar cells and manufacturing methods, applied in final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve problems such as high technical cost and difficulty in implementing P-type diffusion technology, and achieve process simplification, easy implementation, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

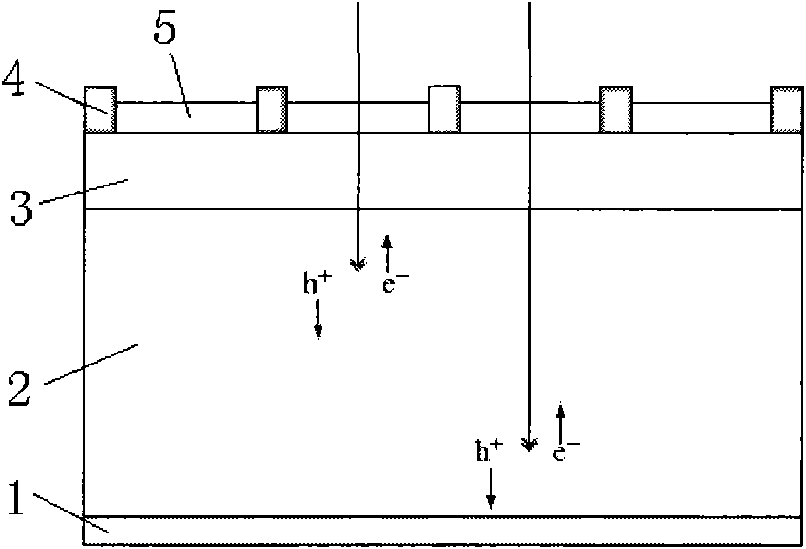

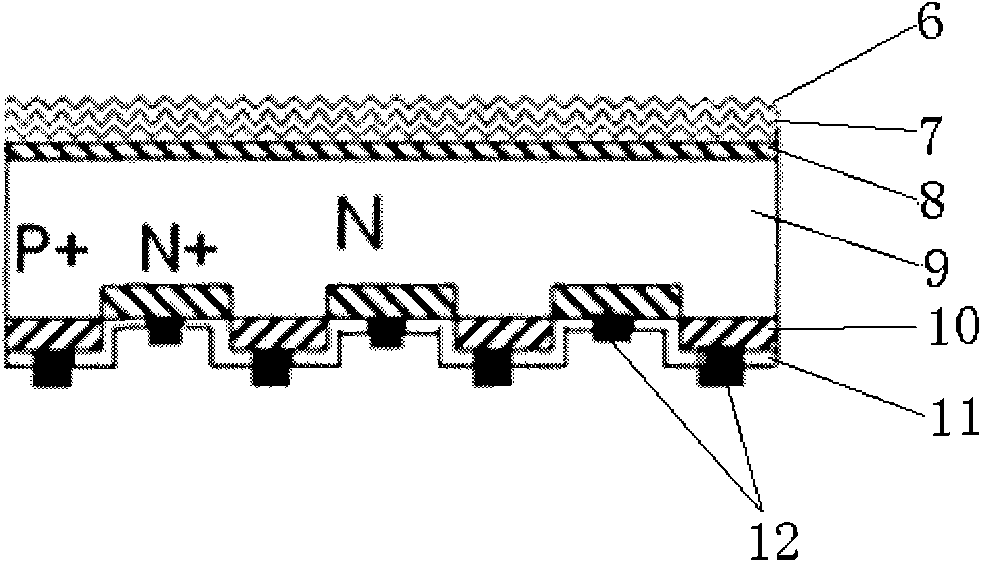

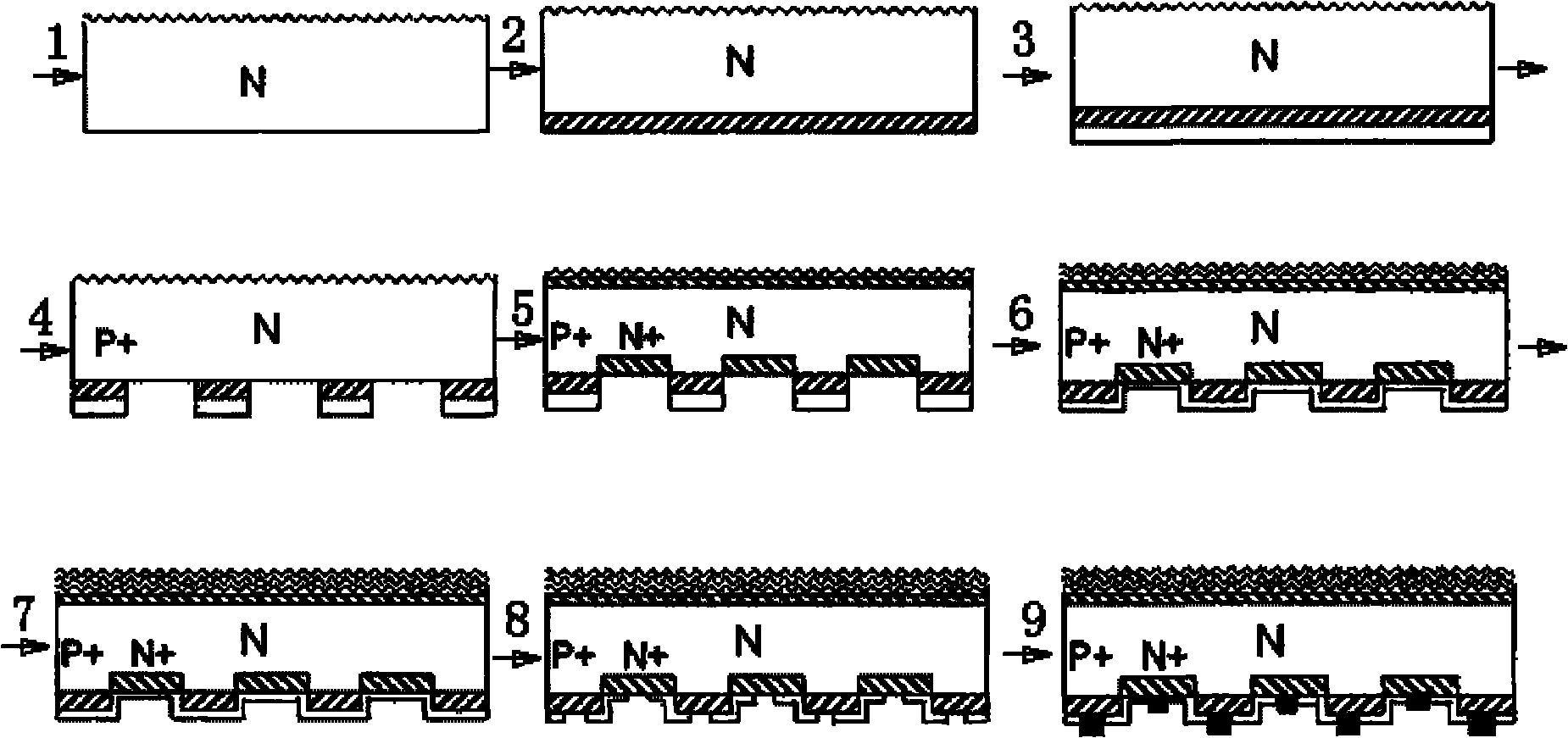

[0029] Specific examples, such as image 3 As shown, the process flow includes steps:

[0030] Step 1, silicon wafer cleaning, surface texture:

[0031] Zone-melting N-type monocrystalline silicon wafers with a thickness of 220-280um are selected as the base material, and the silicon wafers are cleaned with a NaOH solution with a mass fraction of 2%-15% and a temperature between 60°C and 90°C to remove the silicon wafers. The surface is damaged, and the front side of the silicon wafer is made into an inverted pyramid suede with a mixed solution of KOH and IPA (isopropanol).

[0032] Step 2, growing a P-type doped silicon dioxide layer:

[0033] A P-type doped layer is grown on the back of the substrate. The doping source can be boron or other P-type dopants. The P-type doped layer can be deposited by conventional techniques such as atmospheric pressure chemical vapor deposition and plasma enhanced chemical vapor deposition. Deposited by various deposition methods, the thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com