Wave-soldering brazing filler metal active agent

An active agent and wave soldering technology, applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., to achieve uniform heat distribution, improve welding process, and improve wettability and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

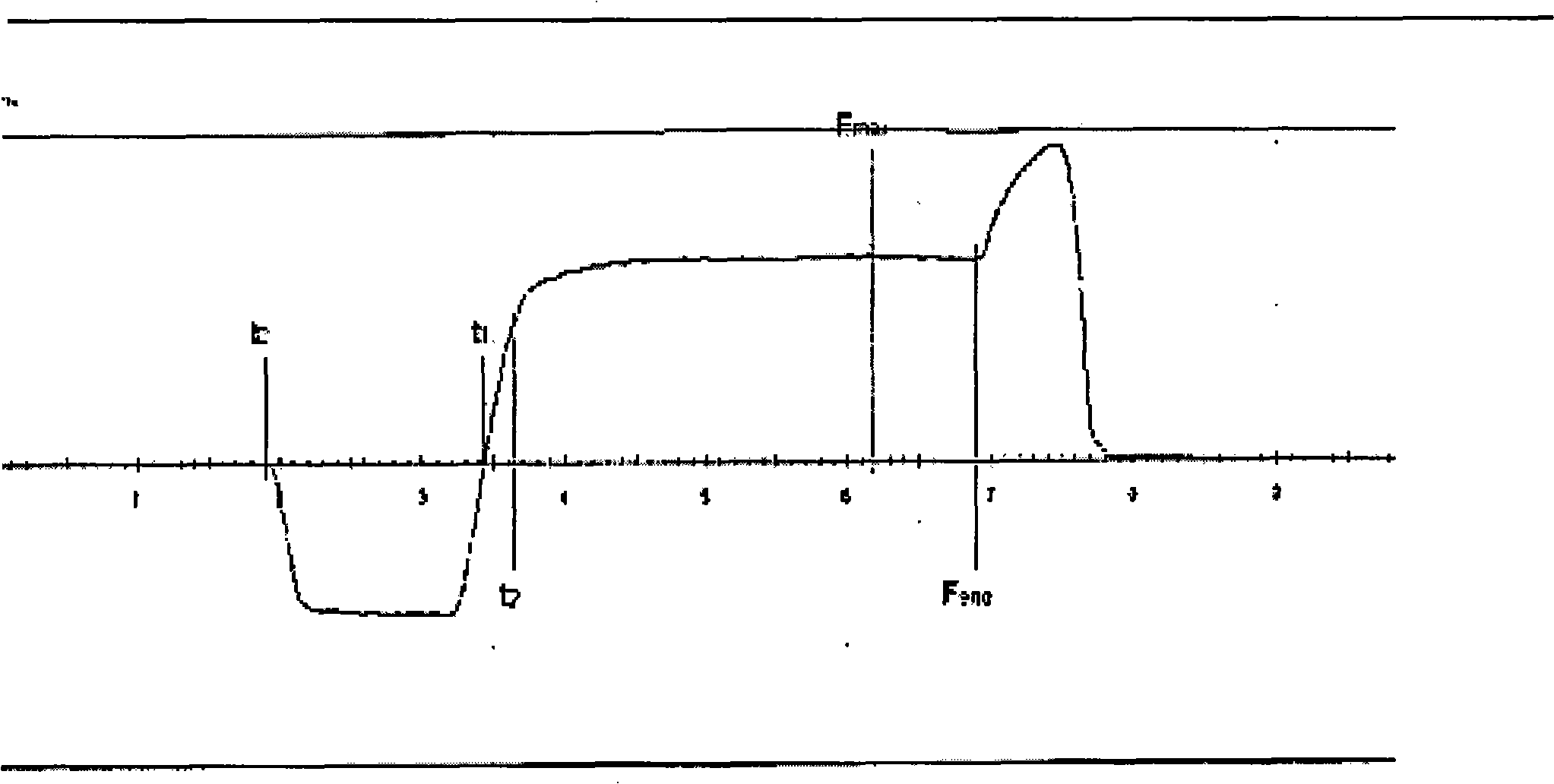

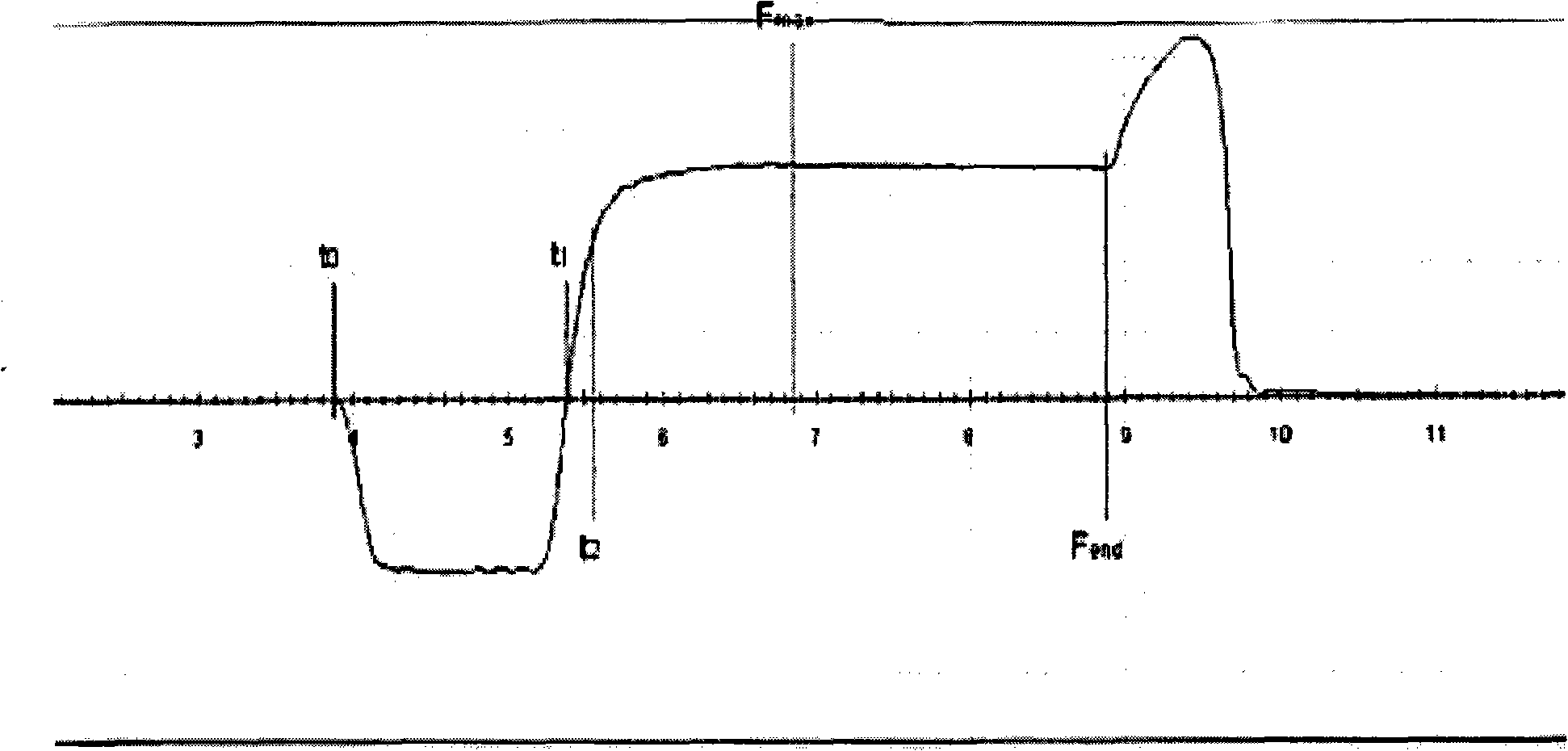

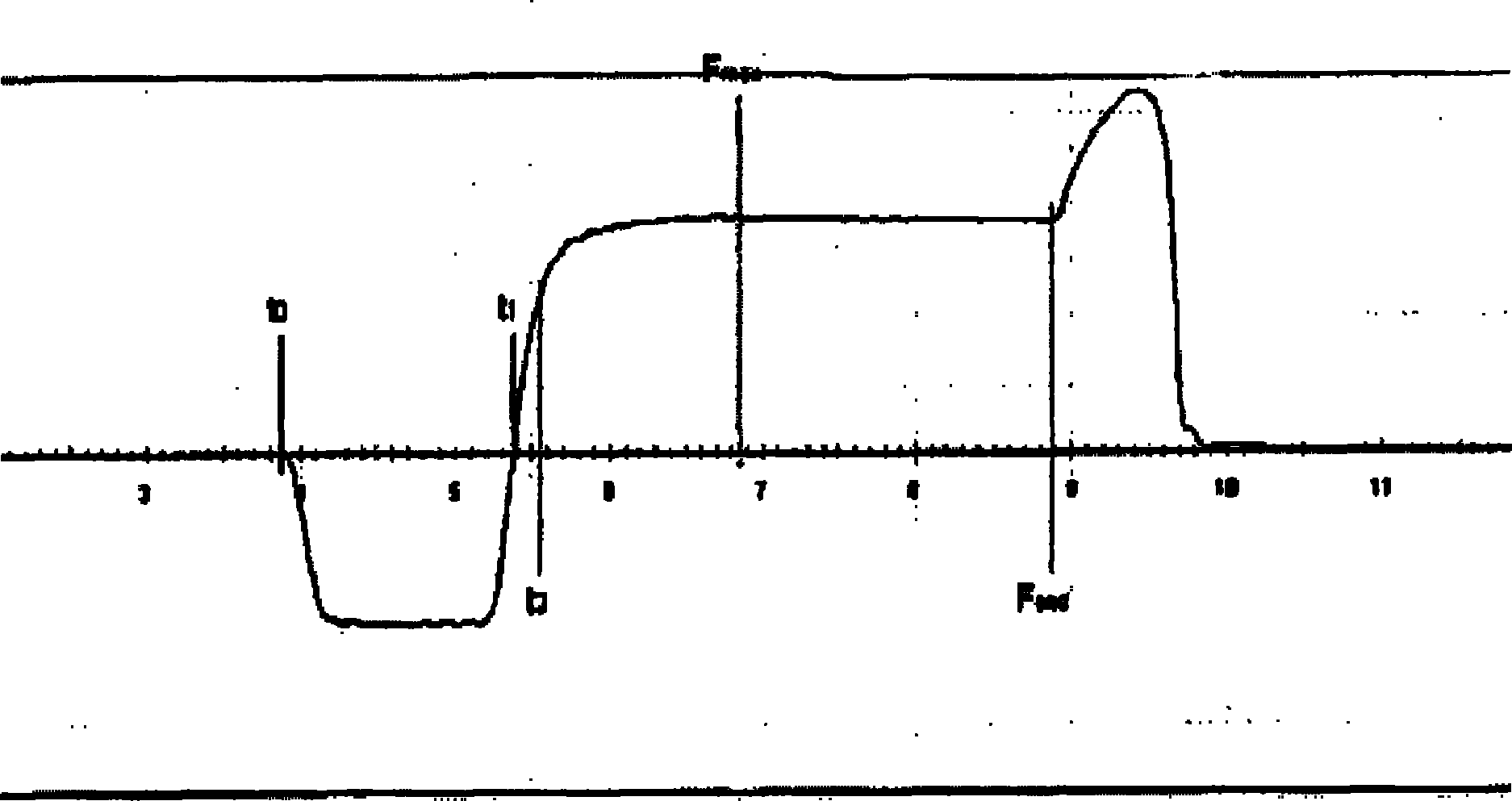

Image

Examples

Embodiment Construction

[0039] The wave soldering solder activator used in the present invention can be a dimer acid, a trimer acid or a mixture of the above two acids. In one embodiment of the present invention, take commercially available dimer acid and trimer acid as active agent, in fact, dimer acid or trimer acid or the mixture of both can be used as active agent, and as required, also Alcohols such as nonylphenol ethoxylate or isopropanol can be added to reduce the concentration of the active agent. The specific operating steps of using the wave soldering solder activator of the present invention are as follows:

[0040] 1. When the wave crest is normally opened for melting tin, clean up the tin slag, and leave about 2-3 kg of tin slag on the tin surface;

[0041] 2. In the tin furnace, use ROHS-compliant metal sheets to control the direction of tin flow, so that tin liquid and tin slag flow out to one end of the tin furnace that is convenient to operate, and then make a reduction area at this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com