Sewage treatment device for synchronically removing sulfur, nitrogen and carbon and for recycling elemental sulfur

A sewage treatment equipment, elemental sulfur technology, applied in water/sludge/sewage treatment, sulfur preparation/purification, anaerobic digestion treatment, etc., can solve the problems of difficult recovery of elemental sulfur and low recovery rate, and achieve recovery efficiency High, low energy consumption, efficient recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

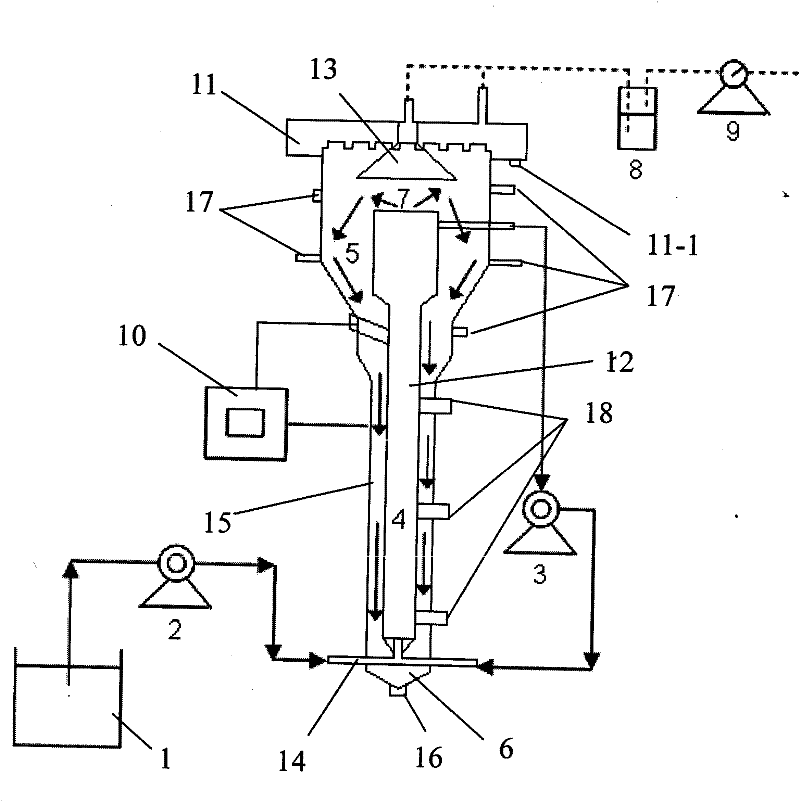

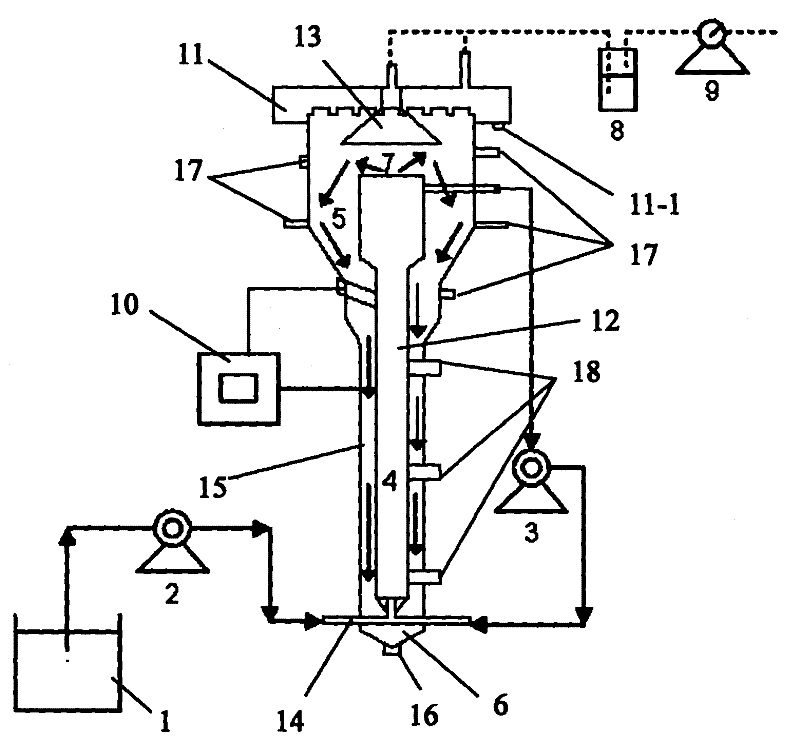

[0010] Specific implementation mode one: as figure 1 As shown, the sewage treatment equipment for synchronously removing sulfur, nitrogen and carbon and recovering elemental sulfur described in this embodiment includes a water inlet pump 2, a return pump 3, an overflow weir 11, a reactor 12, a gas collecting hood 13, and a gas washing bottle 8. The sewage treatment equipment also includes a tee 14, an elemental sulfur collection container 15 and an elemental sulfur discharge pipe 16, the reactor 12 is arranged in the elemental sulfur collection container 15, the gas collection hood 13 is located above the reactor 12 and The gas collection hood 13 is arranged in the upper end of the reactor 12, and the overflow weir 11 is arranged on the upper end surface of the reactor 12, and the upper end of the gas collection hood 13 and the upper end of the overflow weir 11 are all communicated with the gas washing bottle 8, and the overflow The lower end of the weir 11 is provided with a ...

specific Embodiment approach 2

[0012] Specific implementation mode two: as figure 1 As shown, the outer diameter of the upper end of the reactor 12 in this embodiment is larger than the outer diameter of the lower end, and the outer diameter of the upper end of the elemental sulfur collection container 15 is larger than the outer diameter of the lower end. The effective increase of the diameter of the upper end of the reactor 12 can slow down the rising velocity of the upper end of the reactor, on the one hand, the sludge in the upper end of the reactor 12 can be allowed to fall back to the lower end of the reactor 12, reducing the loss of reactor biomass, On the other hand, it can effectively prevent the sludge in the reactor from entering the return pipe. The elemental sulfur collection container 15 is a precipitation area for elemental sulfur. The elemental sulfur produced during the biochemical reaction begins to precipitate at the upper end of the elemental sulfur collection container 15, and is finall...

specific Embodiment approach 3

[0013] Specific implementation mode three: as figure 1 As shown, the sewage treatment equipment in this embodiment further includes a plurality of elemental sulfur collection container sampling pipes 17 , and the plurality of elemental sulfur collection container sampling pipes 17 communicate with the side walls of the elemental sulfur collection container 15 respectively. Other compositions and connections are the same as those in Embodiment 1 or 2.

[0014] Specific implementation mode four: as figure 1 As shown, the sewage treatment equipment in this embodiment further includes a plurality of reactor sampling pipes 18, and the plurality of reactor sampling pipes 18 communicate with the reactor 12 respectively. Other components and connections are the same as those in the third embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com