Horticultural composite phase change pipe and preparation method thereof

A technology of composite phase change and inorganic phase change material, applied in the field of horticultural composite phase change pipe and its preparation, can solve the problems of supercooling humidity sensitivity, unfavorable application and the like, achieve low price, improve supercooling and phase change separation, The effect of avoiding the risk of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

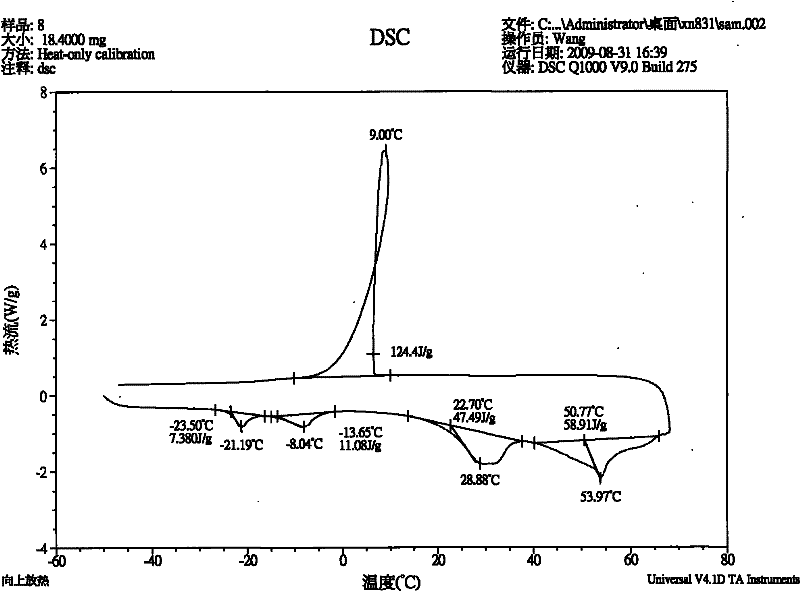

Embodiment 1

[0034] The horticultural composite phase change pipe prepared in this embodiment specifically includes the following steps:

[0035] Step 1: Inorganic phase change material formulation

[0036] Mix the following inorganic phase change materials by mass ratio:

[0037] Na 2 SO 4 : 8.8%, Na 2 HPO 4 12H 2 O: 74%, CaCl 2 : 2.5%, H 2 O: 13.6%, borax (Na 2 B 4 o 7 10H 2 O): 1%, CMC: 0.1%; hereinafter referred to as formula-1.

[0038] Step 2: Heat the inorganic phase change hybrid material to 70°C, and then let it become liquid; stir fully during the heating process to make it a saturated solution;

[0039] Step 3: Use liquid filling equipment to encapsulate the saturated solution with polyethylene pipes. During the encapsulation process, the actual pipe diameter and length of the encapsulation need to be adjusted according to the different building wall bearing capacity and the required heat load. Generally, 0.3m each 3 Left and right, get horticultural composite phase ...

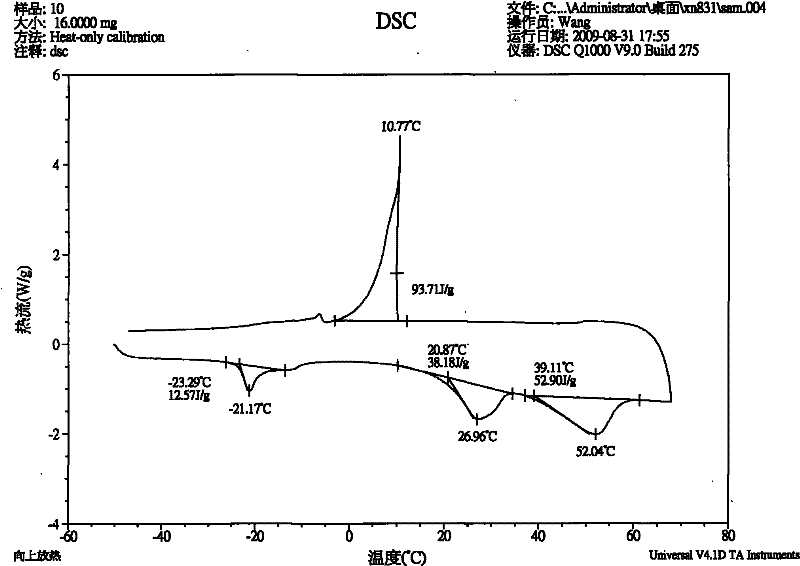

Embodiment 2

[0046] The horticultural composite phase change pipe prepared in this embodiment comprises the following steps:

[0047] Step 1: Inorganic phase change material formulation

[0048] Mix the following inorganic phase change materials by mass ratio: Na 2 SO 4 : 8.8%, Na 2 HPO 4 12H 2 O: 72%, CaCl 2 : 3.5%, H 2 O: 14.6%, borax (Na 2 B 4 o 7 10H 2 O): 1%, CMC: 0.1%; hereinafter referred to as blend-2.

[0049] Step 2: Heat the inorganic phase change hybrid material to 70 degrees Celsius, and then let it become liquid; stir fully during the heating process to make it a saturated solution;

[0050] Step 3: Use liquid filling equipment to encapsulate the saturated solution with polyethylene pipes. During the encapsulation process, the actual pipe diameter and length of the encapsulation need to be adjusted according to the different building wall bearing capacity and the required heat load. Generally, 0.3m each 3 Left and right, get horticultural composite phase change p...

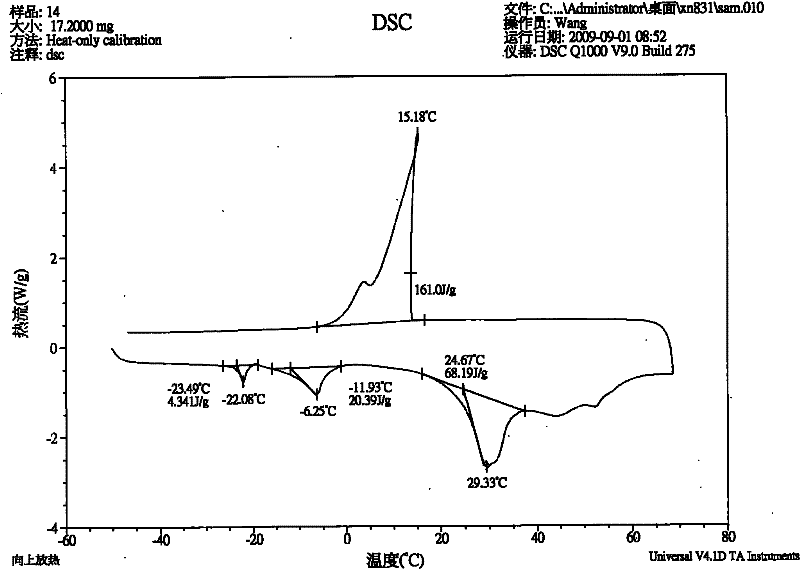

Embodiment 3

[0057] The horticultural composite phase change pipe prepared in this embodiment comprises the following steps:

[0058] Step 1: Inorganic phase change material formulation

[0059] Mix the following inorganic phase change materials by mass ratio: Na 2 SO 4 : 10.6%, Na 2 HPO 4 12H 2 O: 72%, CaCl 2 : 1.5%, H 2 O: 14.9%, borax (Na 2 B 4 o 7 10H 2 O): 1%; hereinafter referred to as blend-3.

[0060] Step 2: Heat the inorganic phase change hybrid material to 70 degrees Celsius, and then let it become liquid; stir fully during the heating process to make it a saturated solution;

[0061] Step 3: Use liquid filling equipment to encapsulate the saturated solution with polyethylene pipes. During the encapsulation process, the actual pipe diameter and length of the encapsulation need to be adjusted according to the different building wall bearing capacity and the required heat load. Generally, 0.3m each 3 Left and right, a horticultural composite phase change pipe is obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| melt | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com