Preparation method of CdSe/CdS core-shell structure quantum dots

A quantum dot and shell structure technology, applied in the field of quantum dots, can solve problems such as high toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a preparation method of CdSe / CdS core-shell structure quantum dots, comprising:

[0027] Take the selenourea aqueous solution and the n-heptane solution of cadmium alkyl carboxylate and mix to obtain the first mixed solution, heat the first mixed solution to 40°C-70°C, stir the first mixed solution to react, from the reaction CdSe quantum dots are separated from the organic phase solution;

[0028] Get the CdSe quantum dots and join in the n-heptane solution of cadmium alkyl carboxylate;

[0029] Mix the thiourea aqueous solution with the n-heptane solution of cadmium alkyl carboxylate containing CdSe quantum dots to obtain a second mixed solution, heat the second mixed solution to 40°C to 70°C, and stir the second mixed solution Liquid reaction to obtain quantum dots with CdSe / CdS core-shell structure;

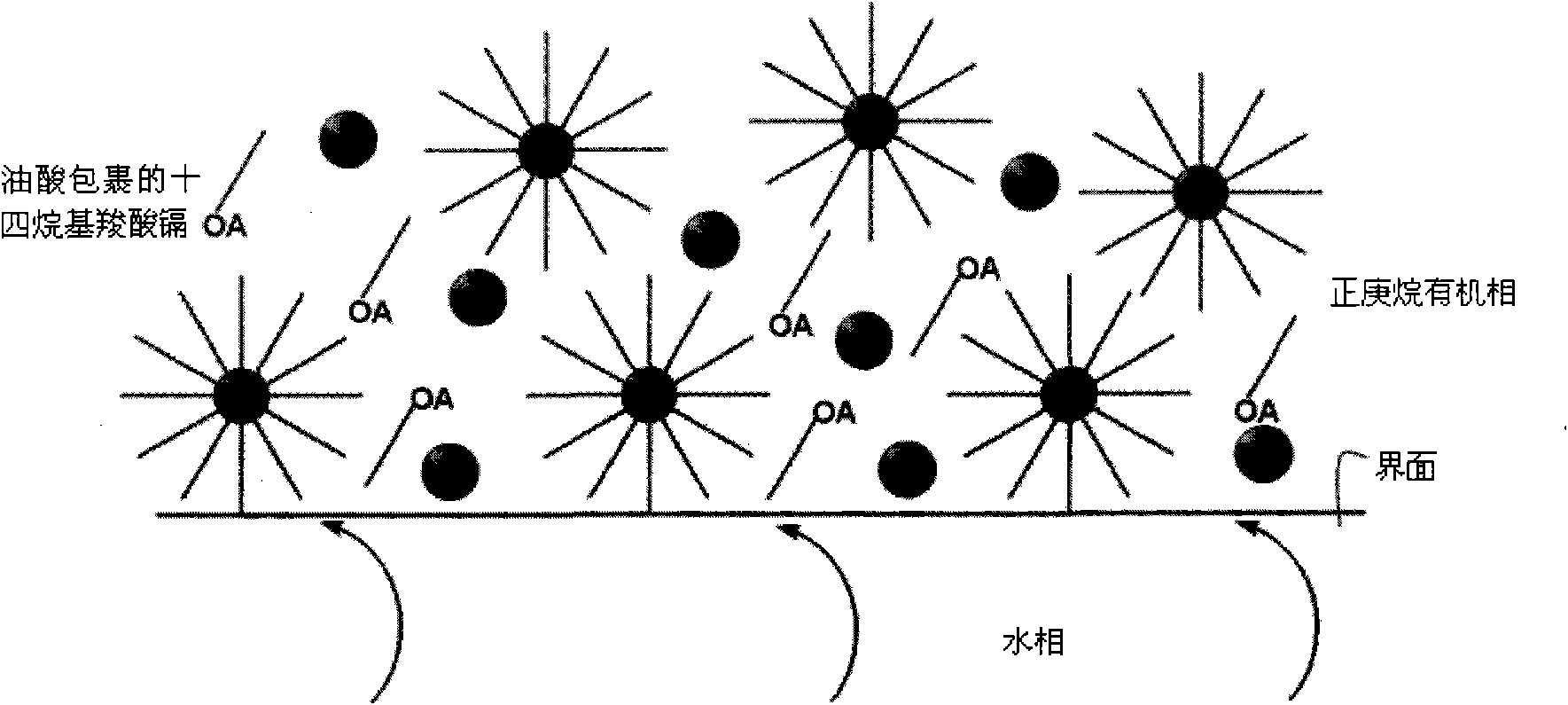

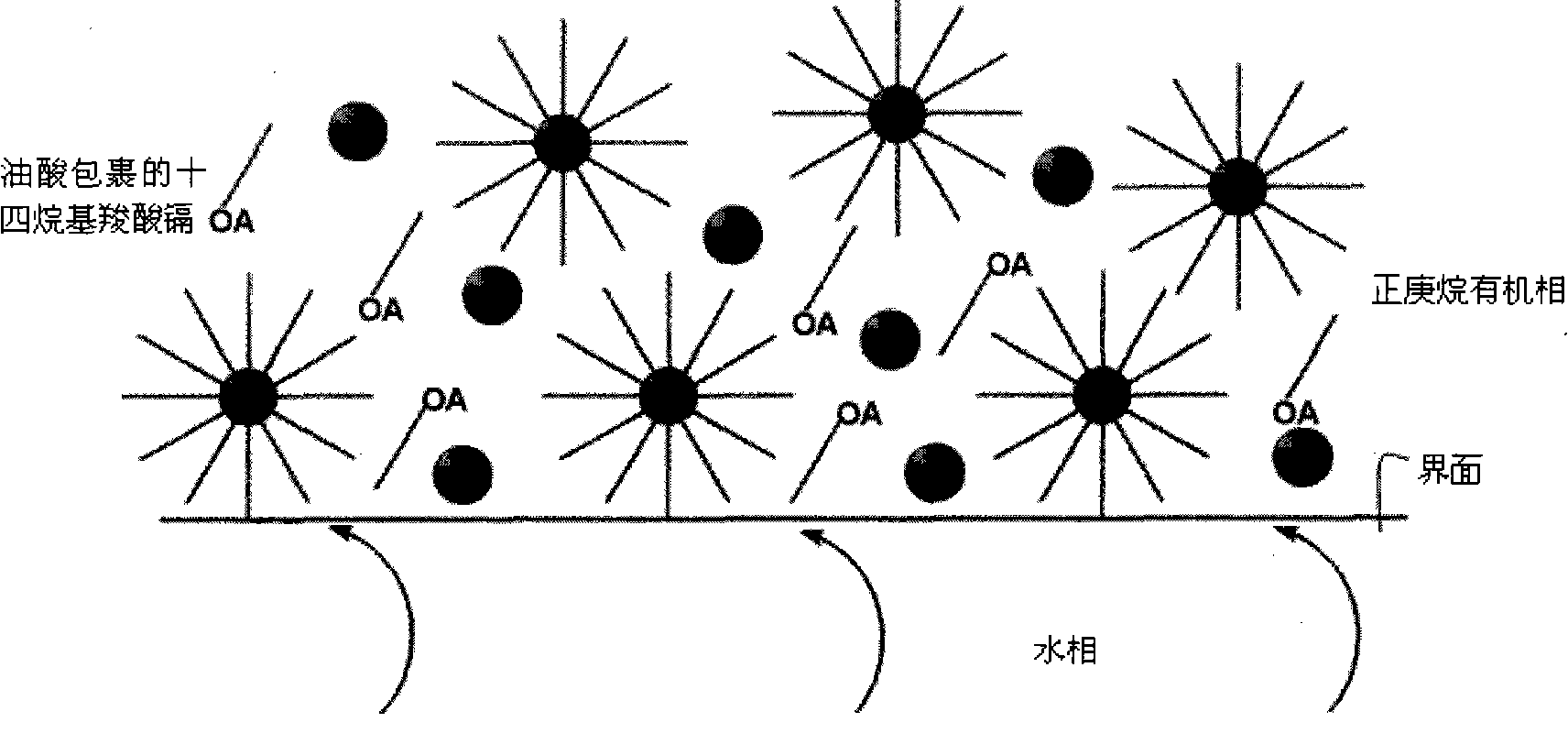

[0030] The n-heptane solution of the cadmium alkyl carboxylate is composed of the cadmium alkyl carboxylate, an organic coating agent and n-he...

Embodiment 1

[0043] Preparation of n-heptane solution of cadmium tetradecyl carboxylate;

[0044] Add 0.1134g of cadmium tetradecyl carboxylate, 1.0ml of oleic acid and 10ml of n-heptane into a 50ml round bottom flask, stir at a constant speed, heat to 80℃~100℃ until a colorless and transparent solution is formed, then cool At room temperature, a n-heptane solution of cadmium tetradecyl carboxylate was obtained.

Embodiment 2

[0047] Preparation of CdSe quantum dots:

[0048] Get 0.0125g selenourea solution and be dissolved in 10ml nitrogen saturated water to obtain selenourea aqueous solution, the n-heptane solution of described selenourea aqueous solution and the cadmium tetradecyl carboxylate prepared in 10ml embodiment 1 in the round bottom flask of 50ml nitrogen gas Mix under protection, seal the round-bottom flask, put it in a 40°C oil bath, stir the mixed liquid in the round-bottom flask at a constant speed, the reaction time is 20min, take out the round-bottom flask and cool to room temperature. Taking out the upper organic phase of the reaction solution, using acetone as a precipitating agent to purify the CdSe quantum dots in the organic phase, and centrifuging to obtain the CdSe quantum dots. Its fluorescence emission peak is at 467nm, and its emission peak shape is symmetrical, but there is tailing, which is caused by defect emission.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com