Purification method for organic waste gas

A technology of organic waste gas and purifier, applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc., can solve the problems of reduced purification efficiency, complex treatment process, low concentration, etc., and achieve reduced load impact, simple treatment process, The effect of high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

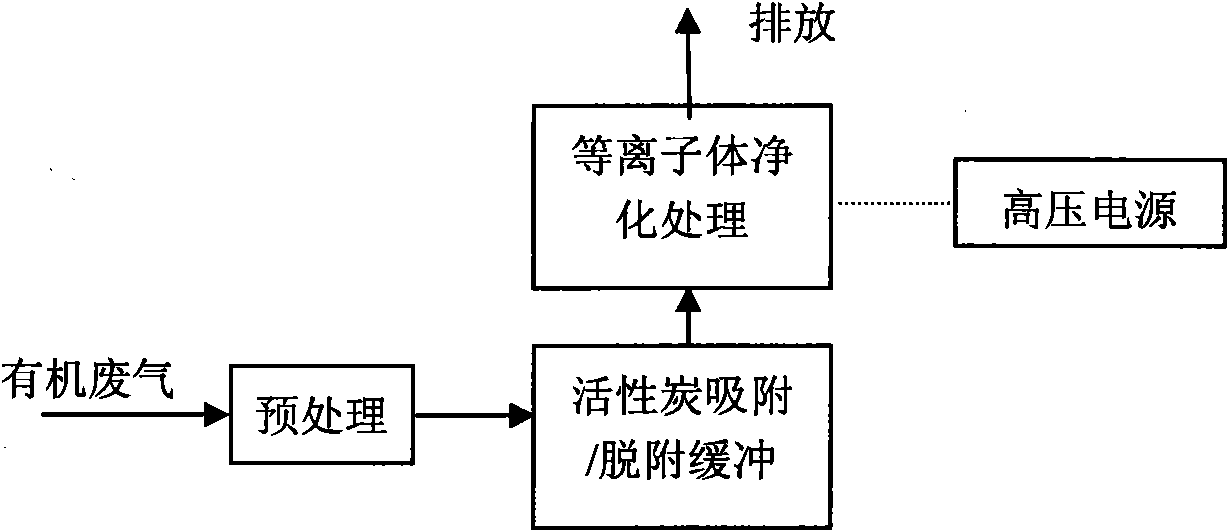

[0019] Such as figure 1 As shown, the concentration is 10-1000mg / m 3 The organic waste gas passes through the filter to remove particulate matter, and the organic waste gas after the removal of particulate matter passes through the granular activated carbon adsorption bed to absorb part of the organic waste gas, and then passes through a high-voltage power supply with a voltage of 10kV and a frequency of 1kHz to perform plasma purification on the organic waste gas. The bulk purification treatment is carried out in a flat-plate plasma purification processor, using the O produced by dielectric barrier discharge 3 、H 2 o 2 ,OH·,H·,O· - High-energy electrons and ultraviolet light interact with pollutants in organic waste gas, and organic pollutants are oxidized and decomposed to obtain carbon dioxide and water, which are directly discharged into the atmosphere.

[0020] When the emission of organic waste gas stops or the concentration of organic waste gas is very low, the acti...

Embodiment 2

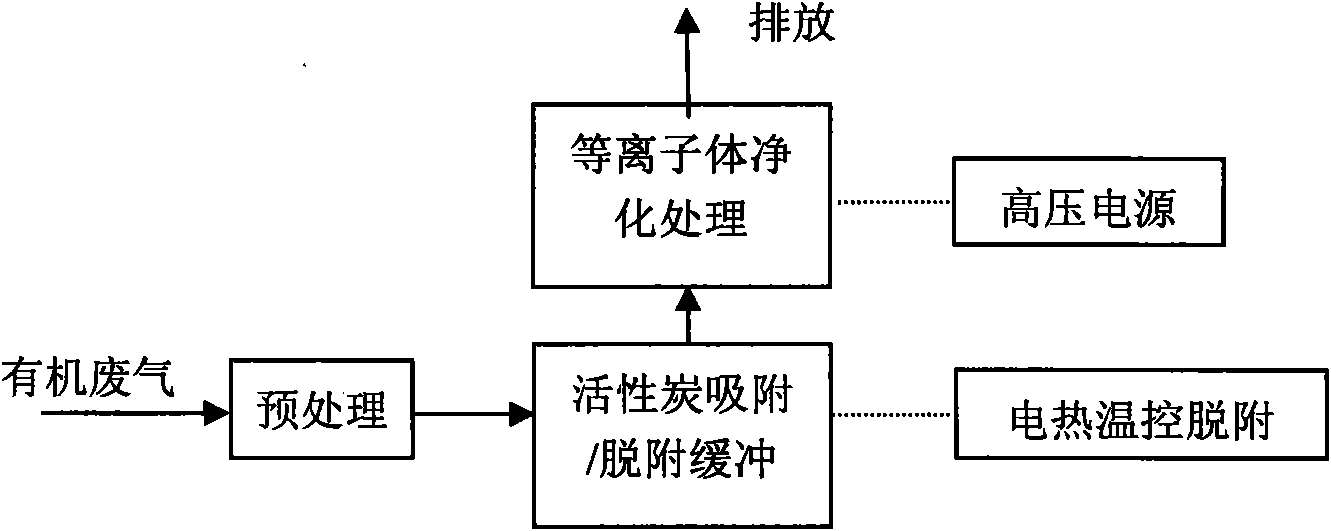

[0022] Such as figure 2 As shown, the concentration is 10-1000mg / m 3 The organic waste gas passes through the filter to remove particulate matter, passes the organic waste gas after removing particulate matter through the honeycomb activated carbon adsorption bed, absorbs part of the organic waste gas, and then performs plasma purification treatment on the organic waste gas through a high-voltage power supply with a voltage of 100kV and a frequency of 10kHz. The body purification treatment is carried out in a flat-plate plasma purification processor, using the O produced by pulsed corona discharge 3 、H 2 o 2 ,OH·,H·,O· - High-energy electrons and ultraviolet light interact with pollutants in organic waste gas, and organic pollutants are oxidized and decomposed to obtain carbon dioxide and water, which are directly discharged into the atmosphere.

[0023] When the emission of organic waste gas stops or the concentration of organic waste gas is very low, the temperature of ...

Embodiment 3

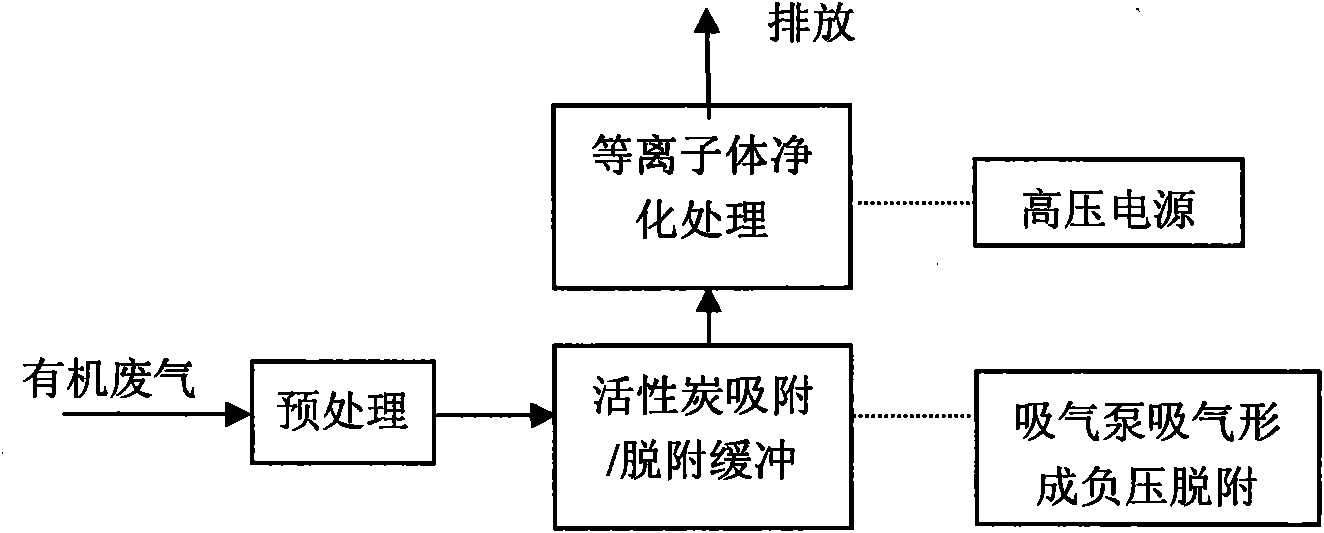

[0025] Such as image 3 As shown, the concentration is 10-1000mg / m 3 The organic waste gas passes through the filter to remove particulate matter, passes the organic waste gas after removing particulate matter through the activated carbon fiber adsorption bed, absorbs part of the organic waste gas, and then performs plasma purification treatment on the organic waste gas through a high-voltage power supply with a voltage of 200kV and a frequency of 20kHz. The purification treatment is carried out in a cylindrical plasma purification processor, using O 3 、H 2 o 2 ,OH·,H·,O· - High-energy electrons and ultraviolet light interact with pollutants in organic waste gas, and organic pollutants are oxidized and decomposed to obtain carbon dioxide and water, which are directly discharged into the atmosphere.

[0026] When the emission of organic waste gas stops or the concentration of organic waste gas is very low, turn on the suction pump to form a negative pressure inside the acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com