Sulfydryl functionalized ordered mesoporous silicon-immobilized Au heterogeneous catalyst and preparation method and application thereof

A heterogeneous catalyst and functionalization technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve heavy metal pollution, and homogeneous catalysts are difficult to reuse , Improve the reaction cost and other issues, to achieve the effect of smooth channels, uniform distribution of active sites, and realization of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of Au heterogeneous catalyst supported by ordered mesoporous silicon with thiol functionalization, comprising the following steps:

[0036] 1) 1.0g P123 (EO 20 PO 70 EO 20 ) (0.17mmol), 8.0g H 2 O and 31mL 2M HCl solution were mixed, stirred at 40°C for 3h in the jacket, and then 9.5mmol tetraethyl orthosilicate (TEOS) was added. Base mercaptan (0.5mmol), continue to stir for 24h, age at 100°C for 24h, filter, wash, and vacuum dry to obtain a white solid powder;

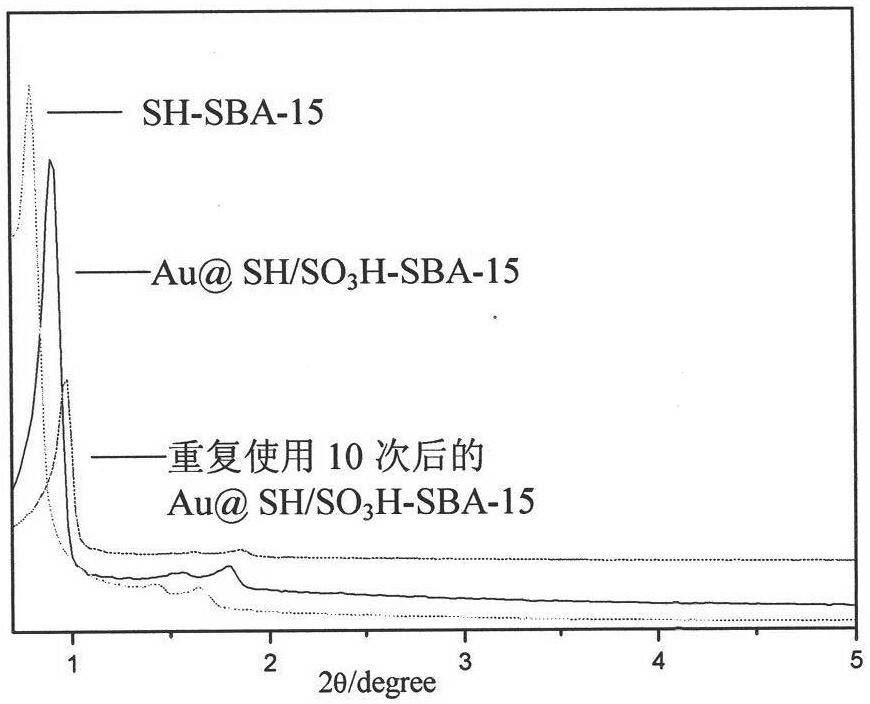

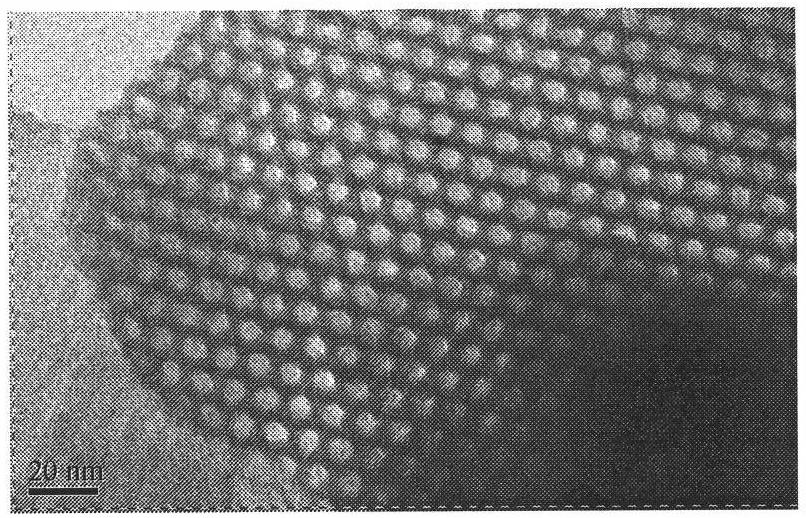

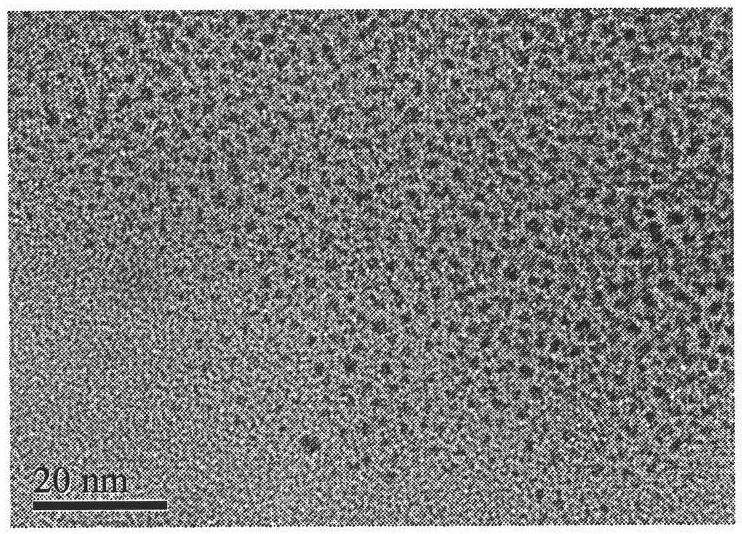

[0037] 2) Grind the above materials with an agate mortar, and finally mix them with HCl / C 2 h 5 OH is extracted, and the mass volume ratio of solid and liquid is 1g: 1000mL; In the described mixed solution of hydrochloric acid and ethanol, the content of hydrochloric acid is 1.0mol / L, and the content of ethanol is 750g / L. The obtained product is ordered mesoporous silicon functionalized with mercapto groups, represented by SH-SBA-15. The small angle XRD picture is as follows figure...

Embodiment 2

[0044] A preparation method of Au heterogeneous catalyst supported by ordered mesoporous silicon with thiol functionalization, comprising the following steps:

[0045] 1) 0.9g P123 (EO 20 PO 70 EO20 ) (0.16mmol), 8.0g H 2 O and 31mL of 2M HCl solution were mixed, stirred at 40°C for 3h in the jacket, and then added (9.6mmol) orthoethyl silicate (TEOS). After 90min of prepolymerization of TEOS, 3-trimethoxysilane Propyl mercaptan (0.4mmol), continued to stir for 22h, aged at 100°C for 24h, filtered, washed, and vacuum dried to obtain a white solid powder;

[0046] 2) Grind the above materials with an agate mortar, and finally mix them with HCl / C 2 h 5 OH for extraction to obtain ordered mesoporous silicon functionalized with mercapto groups; represented by SH-SBA-15. The mass volume ratio of solid and liquid is 1g:900mL; in the mixed solution of hydrochloric acid and ethanol, the content of hydrochloric acid is 1.1mol / L, and the content of ethanol is 750g / L.

[0047] 3) A...

Embodiment 3

[0049] A preparation method of Au heterogeneous catalyst supported by ordered mesoporous silicon with thiol functionalization, comprising the following steps:

[0050] 1) 1.1g P123 (EO 20 PO 70 EO 20 ) (0.19mmol), 9.0g H 2 O and 31mL of 2M HCl solution were mixed, stirred at 40°C for 3h in a jacketed jacket, and then (9.7mmol) tetraethyl orthosilicate (TEOS) was added. After TEOS was prepolymerized for 90min, 3-trimethoxysilane was added n-Propylmercaptan (0.3mmol), continue to stir for 26h, age at 100°C for 24h, filter, wash, and vacuum dry to obtain a white solid powder;

[0051] 2) Grind the above materials with an agate mortar, and finally mix them with HCl / C 2 h 5 OH for extraction to obtain ordered mesoporous silicon functionalized with mercapto groups; represented by SH-SBA-15. The mass volume ratio of solid and liquid is 1g:800mL; in the mixed solution of hydrochloric acid and ethanol, the content of hydrochloric acid is 0.8mol / L, and the content of ethanol is 65...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com