Pyrolytic synthesis method for water-soluble fluorescent carbon nano-particles

A carbon nanoparticle and synthesis method technology, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems that are not suitable for large-scale preparation, complex post-processing, strong acid oxidation, etc., and achieve low price, simple process method, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: The specific preparation steps of this embodiment are as follows:

[0023] (1) First, weigh 1.0 g of EDTA-2Na with an electronic balance, and evenly spread it on the bottom of the quartz boat.

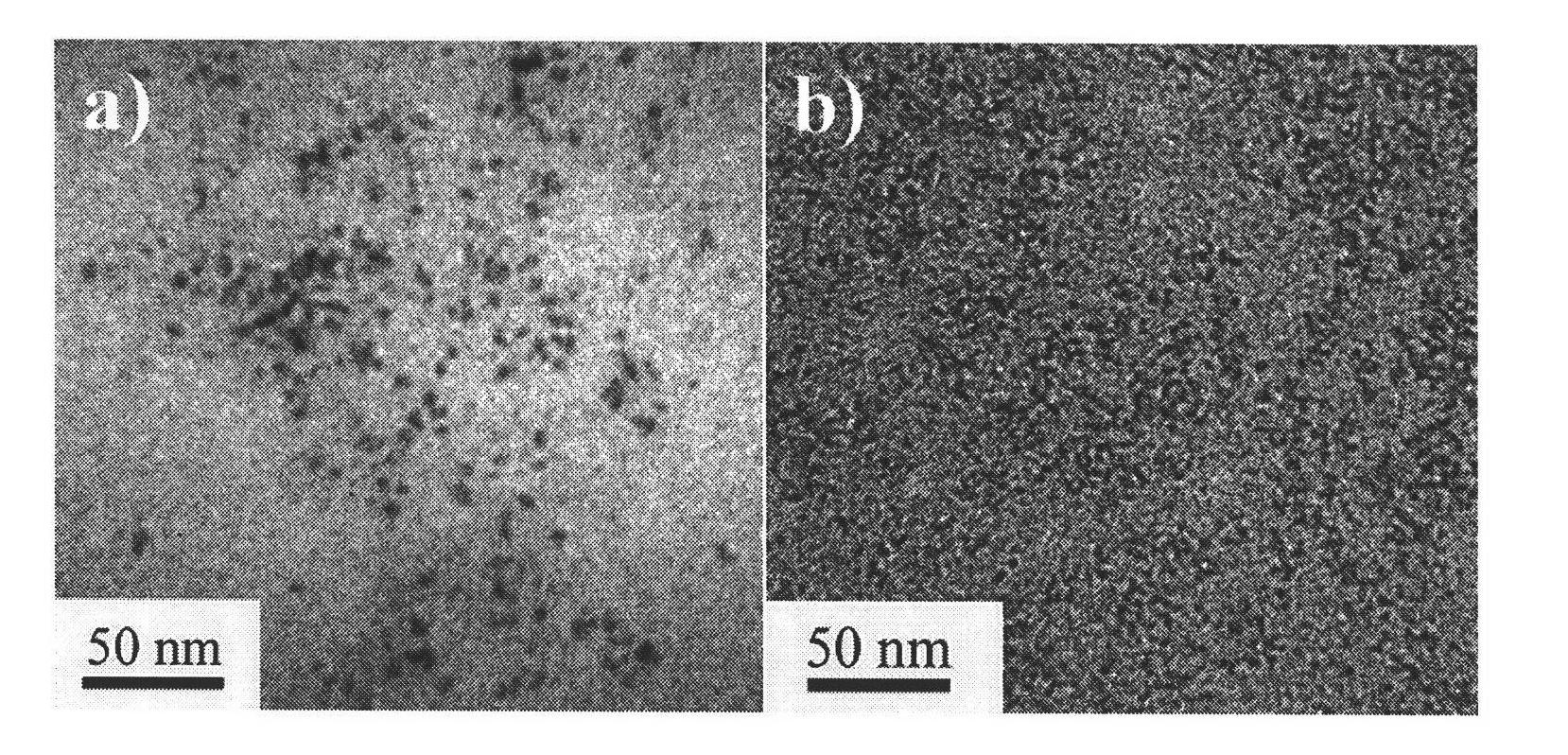

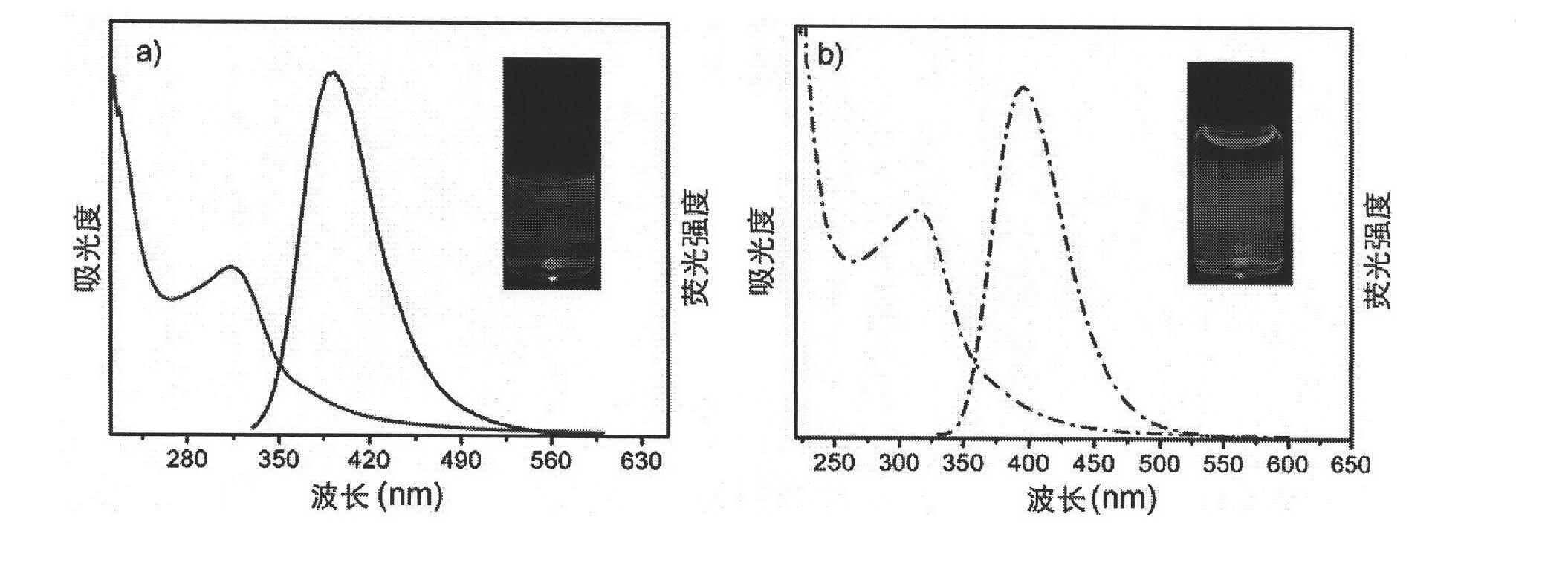

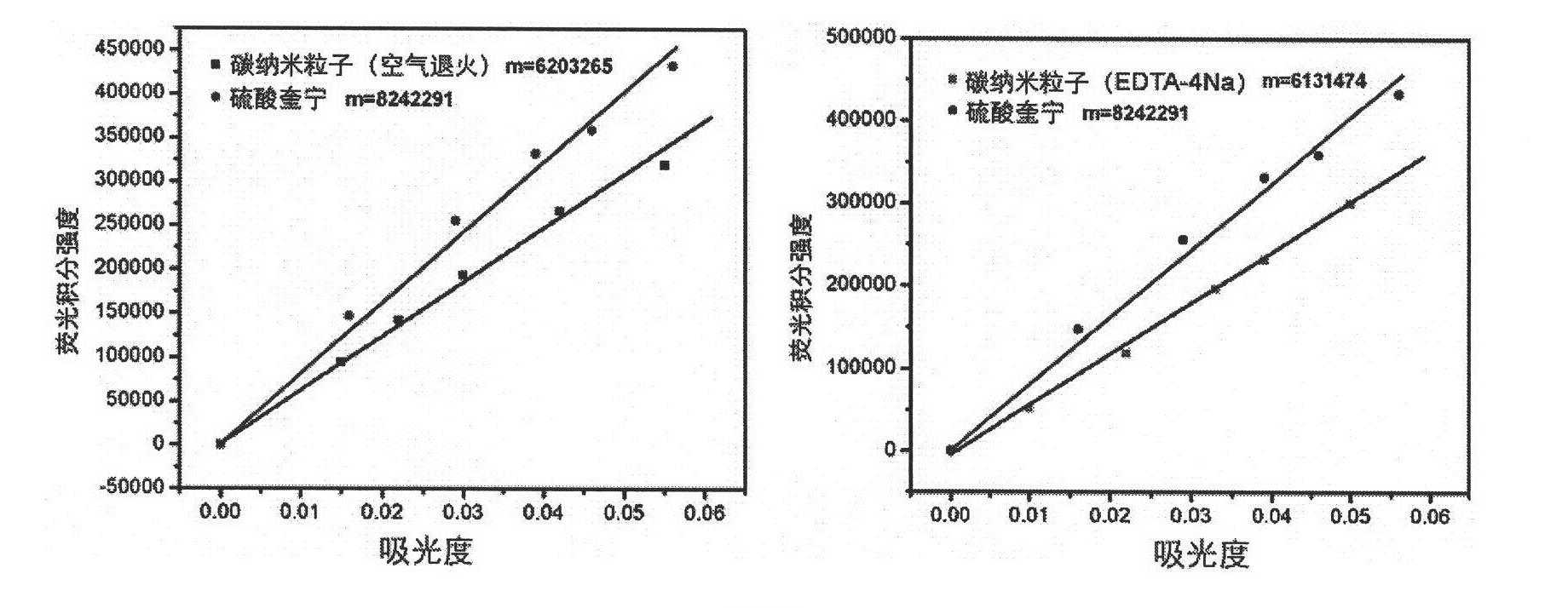

[0024] (2) Put the quartz boat into the tube furnace, N 2 It was calcined at 400°C for 2 hours under protection, and the heating rate was 10°C / min. After calcining, the sample was ground into powder.

[0025] (3) Spread the obtained powder evenly on the bottom of the quartz boat, put it into a tube furnace, and anneal at 400° C. for 15 minutes in air, then take out the quartz boat, and collect the sample powder after cooling.

[0026] (4) Dissolve the obtained powder in 10 mL of ethanol, place it in an ultrasonic oscillator for 5 to 10 minutes, and centrifuge at a high speed (15,000 rpm) to obtain the supernatant, repeat 2-3 times, and concentrate the supernatant by rotary evaporation ( Contains a small amount of ethanol).

[0027] (5) Pour the concentrated solu...

Embodiment 2

[0028] Embodiment 2: The specific preparation steps of this embodiment are as follows:

[0029] (1) First, weigh 1.0 g of EDTA-4Na with an electronic balance, and evenly spread it on the bottom of the quartz boat.

[0030] (2) Put the quartz boat into the tube furnace, N 2 It was calcined at 400°C for 2 hours under protection, and the heating rate was 10°C / min. After calcining, the sample was ground into powder.

[0031] (3) Dissolve the obtained powder in 10 mL of ethanol, place it in an ultrasonic oscillator for 5 to 10 minutes, and centrifuge at a high speed (15,000 rpm) to obtain the supernatant, repeat 2-3 times, collect the supernatant, and rotavap It is concentrated (contains a small amount of ethanol).

[0032] (4) Pour the concentrated solution into a 50mL beaker and dry in an oven at a temperature of 60-80°C for 7-16 hours to finally obtain water-soluble fluorescent carbon nanoparticles.

[0033] The raw materials EDTA-2Na and EDTA-4Na used in the above examples w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| full width at half maximum | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com