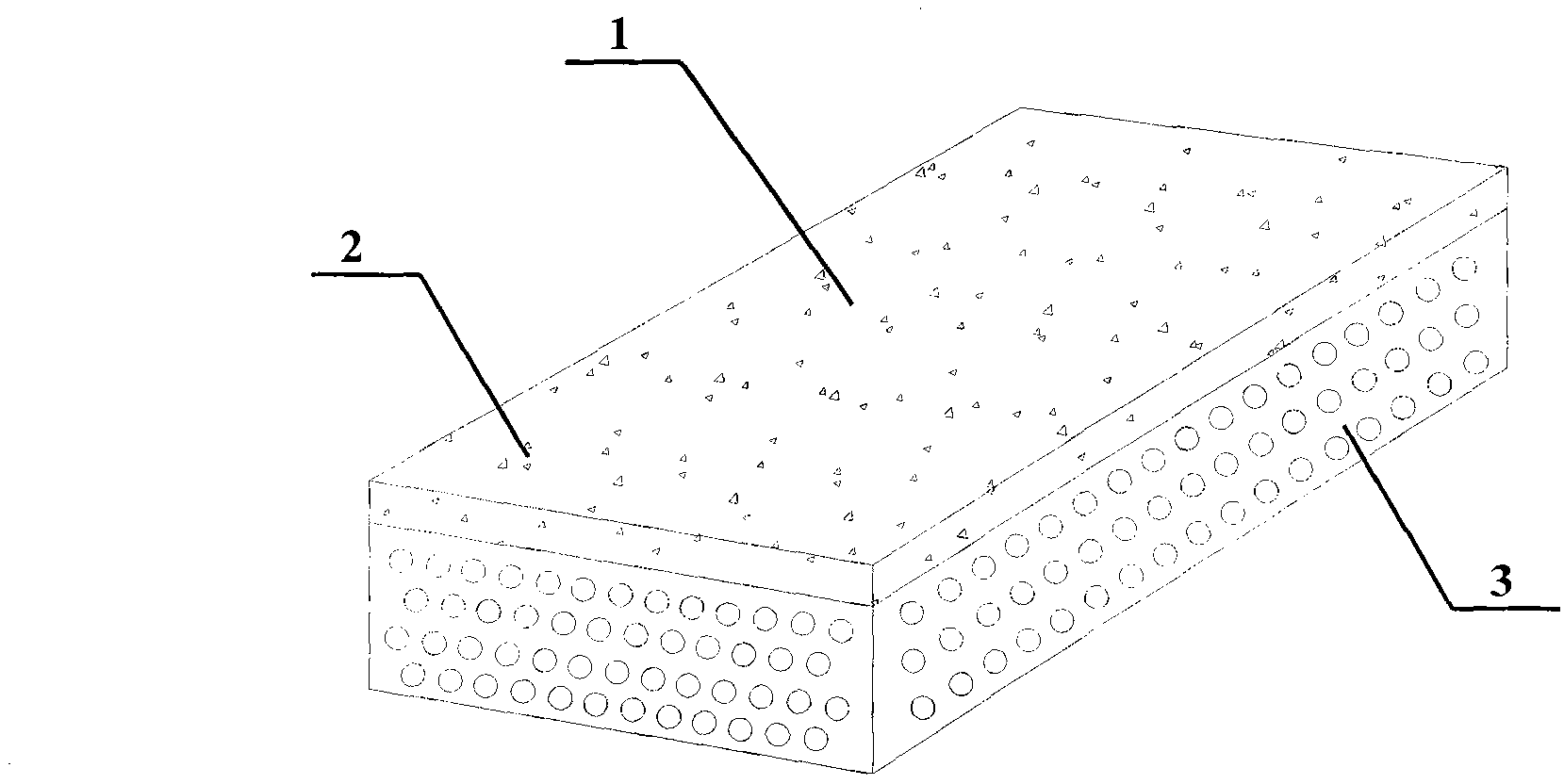

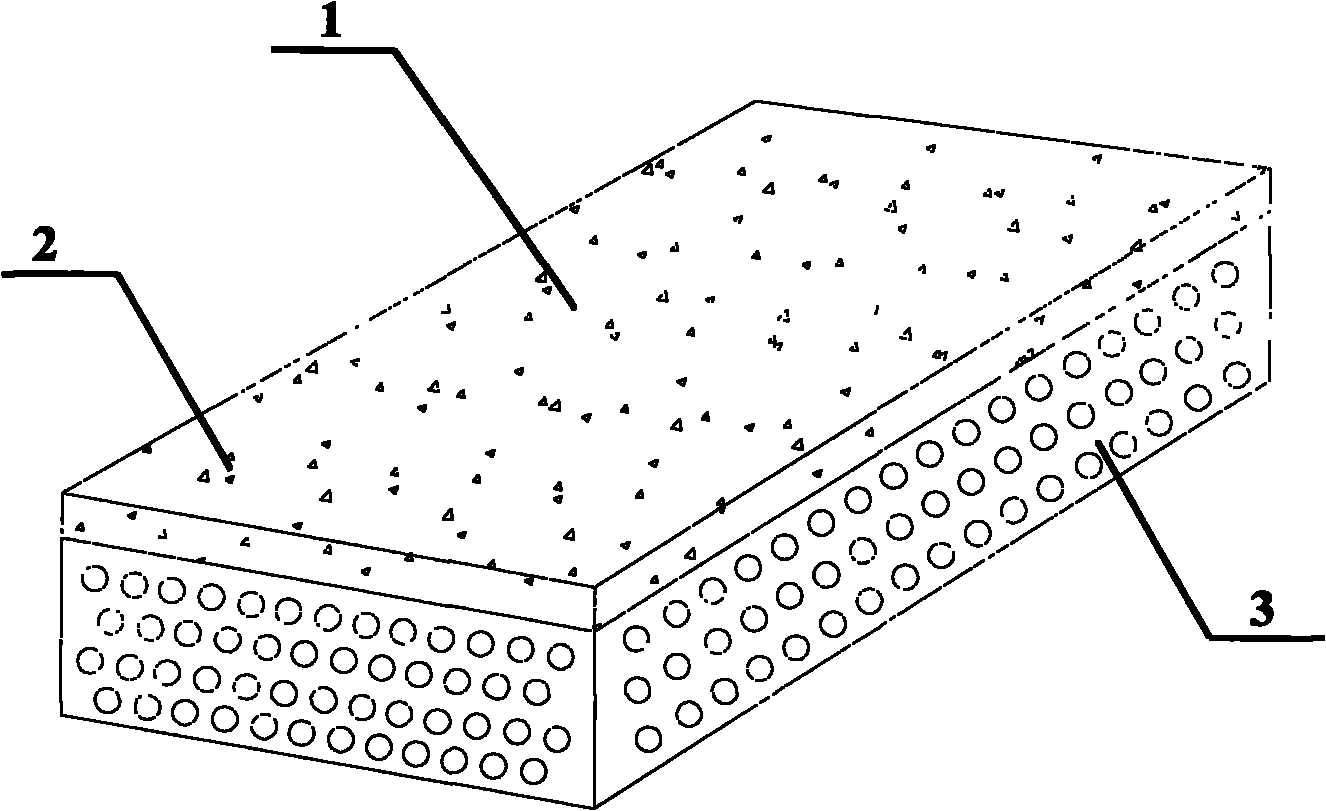

External heat insulation board of flameproof external wall made of cement and polystyrene particle

A technology of external wall insulation and polystyrene particles, applied in thermal insulation, building components, sustainable waste treatment, etc., can solve problems such as falling off, poisoning coma, death, etc., and achieve the effect of convenient building construction, light weight and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

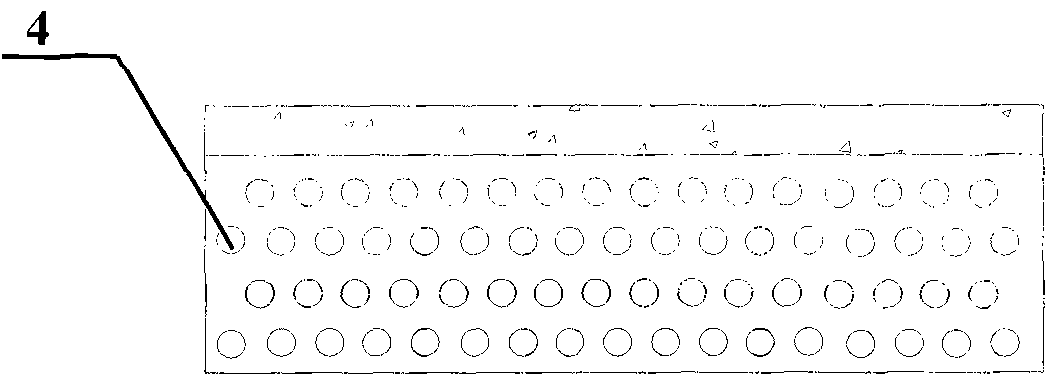

[0026] After mixing fast-hardening sulfoaluminate cement, polyphenylene particles, vitrified microbeads, sawdust, and naphthalene-based water reducer, add water and VAE emulsion to stir to form a slurry, inject it into a molding mold, and release the slurry after hardening to form Insulation layer for exterior insulation boards. After mixing the rapid-hardening sulfoaluminate cement, quartz sand and glass fiber, add water, polycarboxylate superplasticizer, and VAE emulsion to stir to form a slurry, inject it into a mold, and release the slurry after hardening to form an external wall insulation The protective layer of the board. Use cement mortar to bond the protective layer on the upper surface of the insulation layer, pressurize and shape, dry and cure, and after the cement mortar hardens, a cement polystyrene particle fireproof external wall insulation board is formed. The thermal insulation layer of the cement polystyrene particle fire-proof external wall insulation board...

Embodiment 2

[0045] The external wall thermal insulation board of this embodiment is basically the same as that of Embodiment 1, and the raw material ratio of its thermal insulation layer is:

[0046] Rapid hardening sulfoaluminate cement 100 parts

[0047] 3 parts polystyrene particles

[0048] Vitrified microbeads 5 parts

[0049] Sawdust 0.8 parts

[0050] Naphthalene superplasticizer 1 part

[0051] 7.5 parts of VAE emulsion;

[0052] The mass ratio of water to material is 0.55.

[0053] Its protective layer raw material proportioning, with embodiment one.

[0054] The board size (length×width, mm) of the cement polystyrene particle fireproof exterior wall insulation board is 1200×600, the thickness is 60mm, and the thickness of the protective layer is 7mm. The technical performance test results are shown in Table 2.

[0055] Table 2

[0056]

Embodiment 3

[0058] The external wall thermal insulation board of this embodiment is basically the same as that of Embodiment 1, and the raw material ratio of its thermal insulation layer is:

[0059] Rapid hardening sulfoaluminate cement 100 parts

[0060] 4 parts polystyrene pellets

[0061] Vitrified microbeads 4 parts

[0062] Sawdust 0.9 parts

[0063] Naphthalene-based water reducer 1.2 parts

[0064] 9 parts of VAE emulsion;

[0065] The mass ratio of water to material is 0.47.

[0066] Its protective layer raw material proportioning is, with embodiment one.

[0067] The board size (length×width, mm) of the cement polystyrene particle fireproof exterior wall insulation board is 1200×600, the thickness is 80mm, and the thickness of the protective layer is 10mm. The technical performance test results are shown in Table 3.

[0068] table 3

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com