Zeolite membrane structures and methods of making zeolite membrane structures

A technology of zeolite and zeolite crystal, applied in the field of zeolite membrane structure, can solve the problems of difficult zeolite membrane, large zeolite crystal, too thick zeolite membrane, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Example 1 - Preparation of Silica Rock-1 and ZSM-5 Seed Layer Particles

[0082] Silicaite and ZSM-5 are MFI type zeolites. In this example, silicalite-1 and ZSM-5 seed particles were grown using the reflow method.

[0083] In the synthesis of silicalite-1 seed crystals, tetraethylorthosilicate (TEOS, 98%, Alfa Aesar), tetrapropylammonium (TPAOH, 40%, Alfa Aesar), pure H 2 O and NaOH to prepare the synthesis solution. TEOS / TPAOH / H 2 The molar ratio of O / NaOH is 1 / 0.15 / 18.8 / 0.008. Synthesis solutions were prepared at room temperature. In this preparation process, first make H 2 O and NaOH were mixed, then TPAOH was added with stirring at room temperature. Then TEOS was added dropwise while stirring. The synthesis solution was continuously stirred for 24 hours, and the color of the final synthesis solution was clear.

[0084] Reflux seeded synthesis was performed at 85°C for 72 hours. The final synthesis solution was filtered through No. 40 filter paper to remove...

Embodiment 2

[0089] Example 2 Coating Zeolite Seed Crystals on α-Alumina Inorganic Porous Carrier

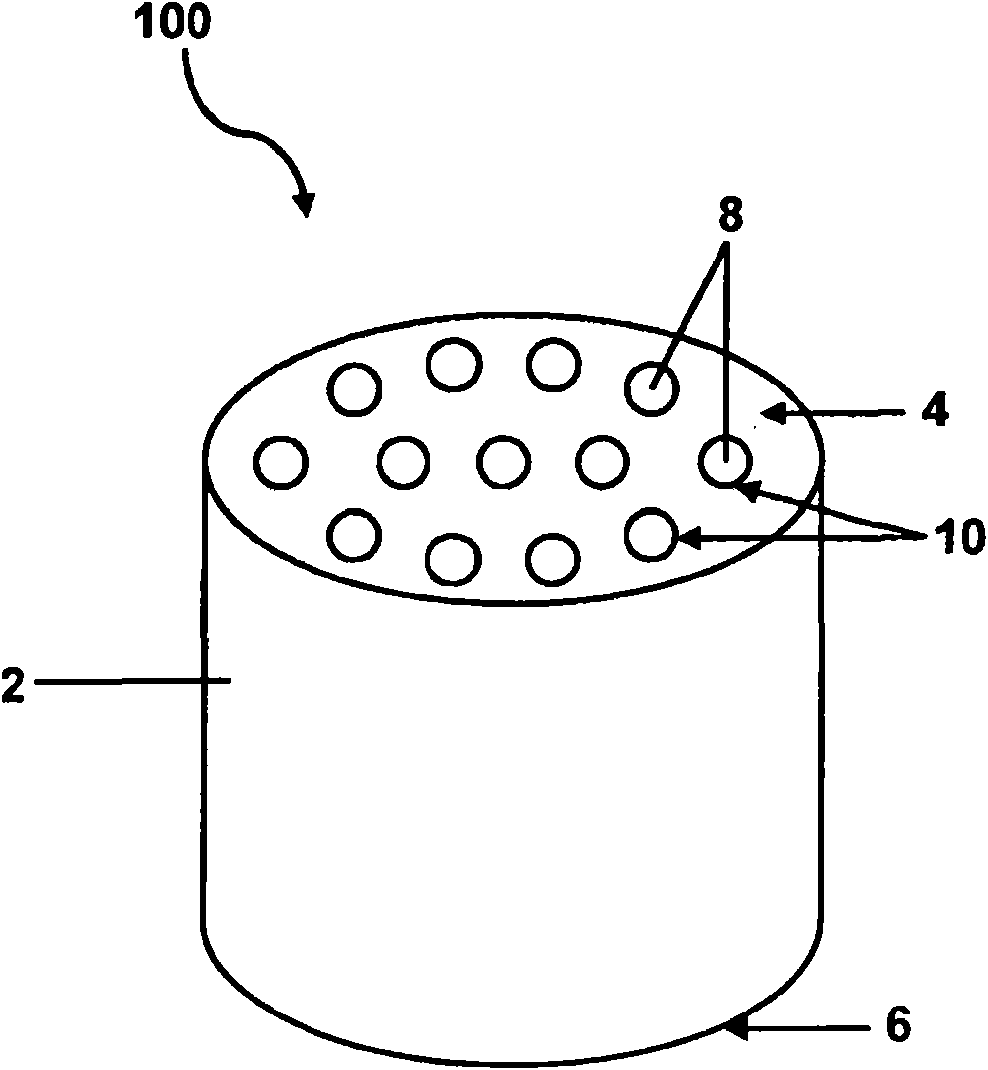

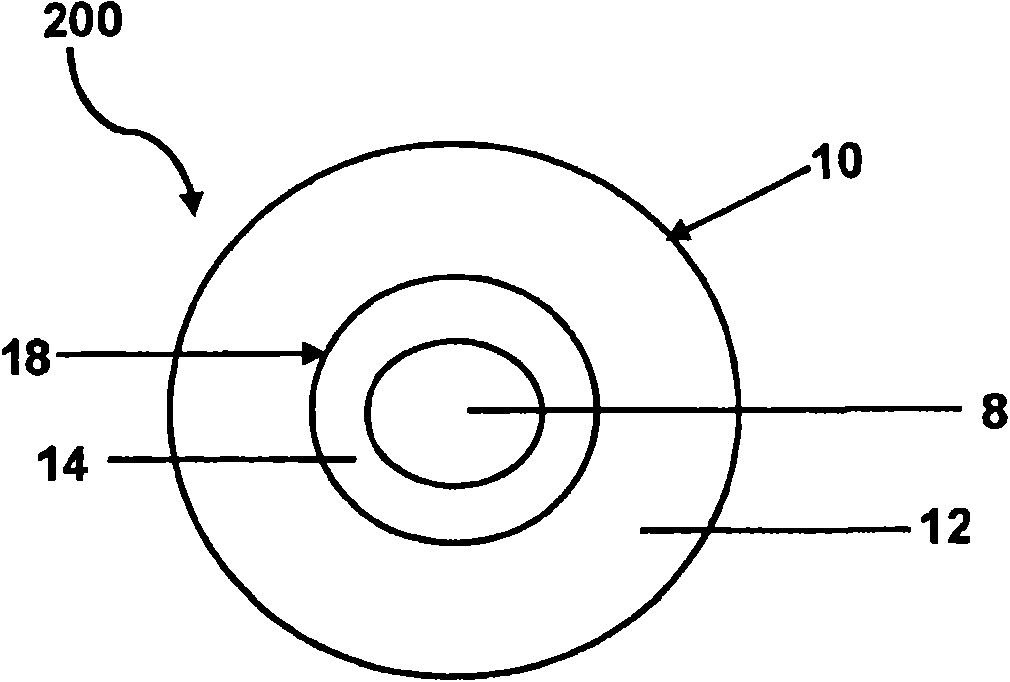

[0090] In this example, 2 pure α-Al with two different pore sizes on the top intermediate layer 2 o 3 Flow coating and Figure 4 Similar silicalite-1 seeds are shown; one has a median pore diameter of about 200 nm and the other has a median pore diameter of about 800 nm. The honeycomb monolithic inorganic porous carrier has an outer diameter of about 9.7mm, and there are 19 circular internal channels of 0.8mm in it, which are uniformly dispersed on the entire cross-section of the honeycomb monolithic inorganic porous carrier. The honeycomb monolithic inorganic porous support was fabricated from alpha-alumina with a median pore diameter of about 10 μm and a median porosity of about 45%. The internal channel surfaces of the honeycomb monolithic inorganic porous support are modified with an intermediate layer of alpha-alumina material.

[0091] The coating mixture for the zeolite seed layer...

Embodiment 3

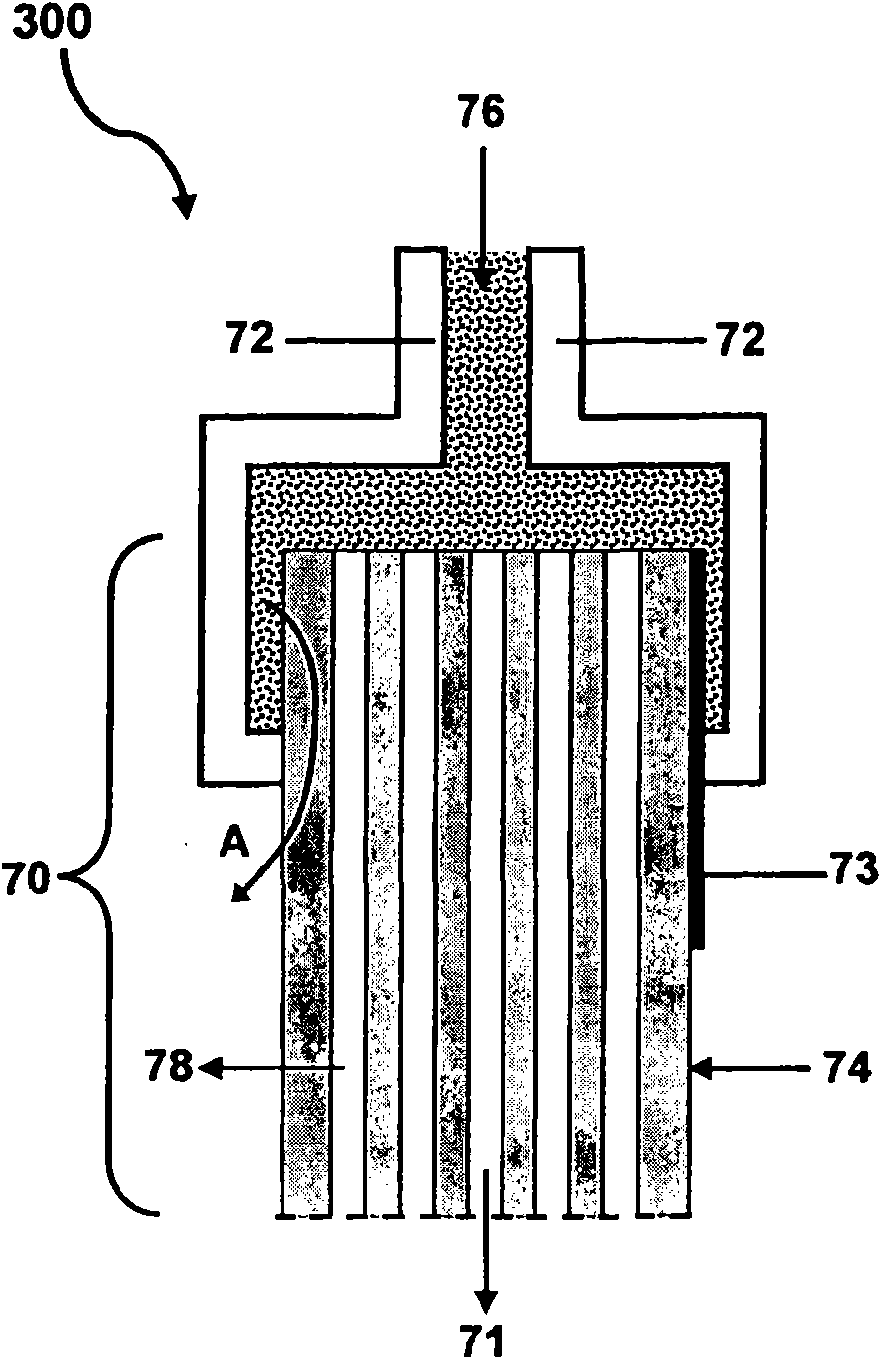

[0094] Example 3 Preparation of symbiotic compact siliceous rock-1 layer by microwave-assisted hydrothermal reaction method

[0095] A silicalite-1 seed-coated support sample was treated by secondary growth using a microwave-assisted hydrothermal reaction method, resulting in symbiosis of the zeolite seed layer to form a dense silicalite-1 film. A synthetic solution for secondary growth was prepared using the same materials used for seed growth as described in Example 1, but with a molar ratio of TEOS / TPAOH / H 2O=1 / 0.12 / 5.8. Microwave Assisted Secondary Growth with Milestone 1600 Microwave Reactor and 100ml pressure cooker.

[0096] A 21 / 2 inch long honeycomb monolithic inorganic porous support (with internal channel surfaces modified with an intermediate layer of α-alumina material, coated with a silicalite-1 seed layer, dried and calcined) was placed vertically on In a pressure cooker, immerse in the synthetic solution. The reaction conditions were set at 400 watts of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com