Preparation method of biodegradable diaphragm for promoting regeneration of periodontal tissue

A periodontal tissue and biological technology, applied in the field of biodegradable periodontal tissue regeneration-promoting film preparation, can solve the problems of short half-life and inactivation of exogenous growth factors, and achieve good in vivo degradability and good biological phase. capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

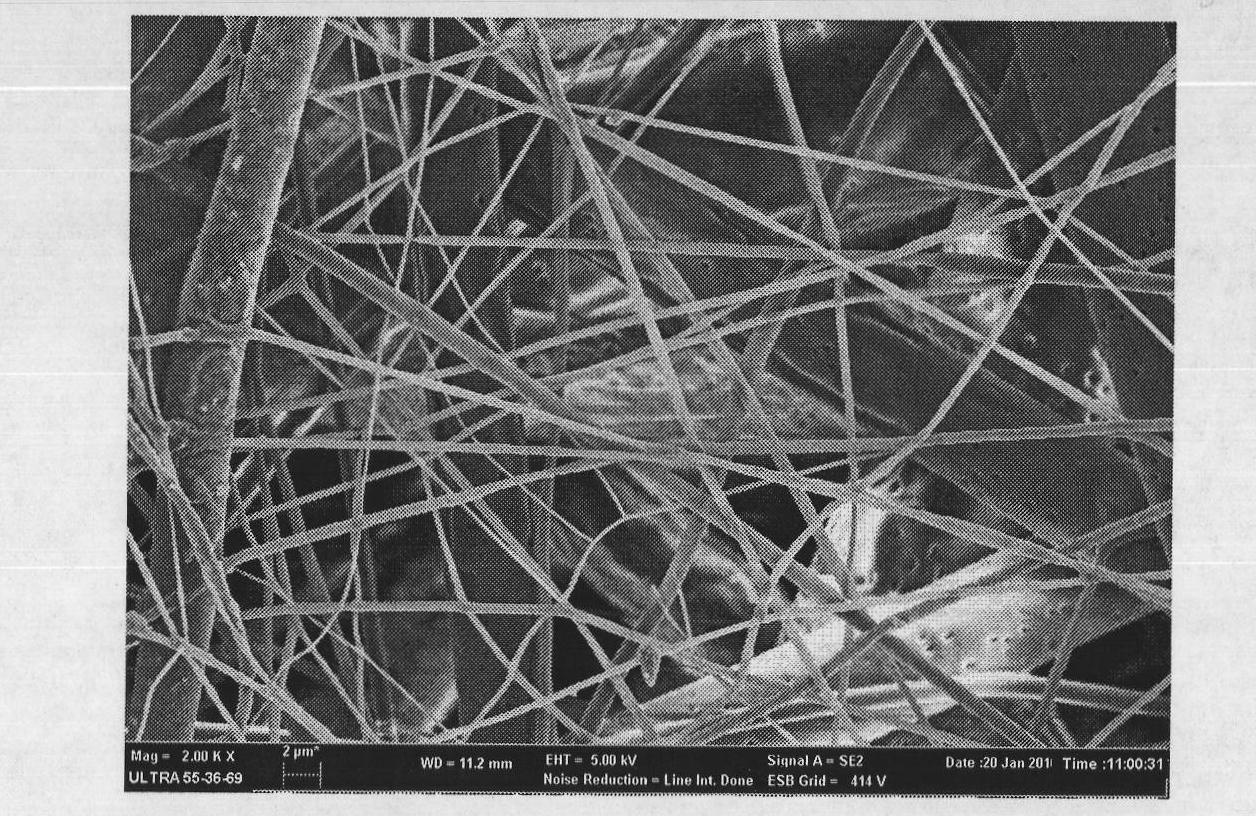

Embodiment 1

[0045] Using PCL as a raw material, it was dissolved in chloroform to prepare a solution with a concentration of 15% (wt). Add this mixture solution to the electrospinning syringe controlled by the syringe pump, set the voltage of the high-voltage generator to 10KV, and the collection distance to 15cm, a film composed of ultrafine fibers with nanometer-scale diameters can be obtained randomly, and then the The film was washed several times with deionized water and dried in vacuum before use. The film is first immersed in a solution of polyethyleneimine (PEI, 1-3 mg / ml) for 5-10 minutes, and then washed with deionized water with pH=7.0. Then BMP-2 and PDGF are made into a solution with a concentration of 0.1-10 μg / ml, and the film is soaked in the solution for 10-30 minutes for adsorption, and then washed with deionized water with pH=7.0. Then immerse in polyallylamine (PAH, 3mg / ml) and polyacrylic acid (PAA, 3mg / ml) solution in turn, cycle 3-4 times, all use deionized water t...

Embodiment 2

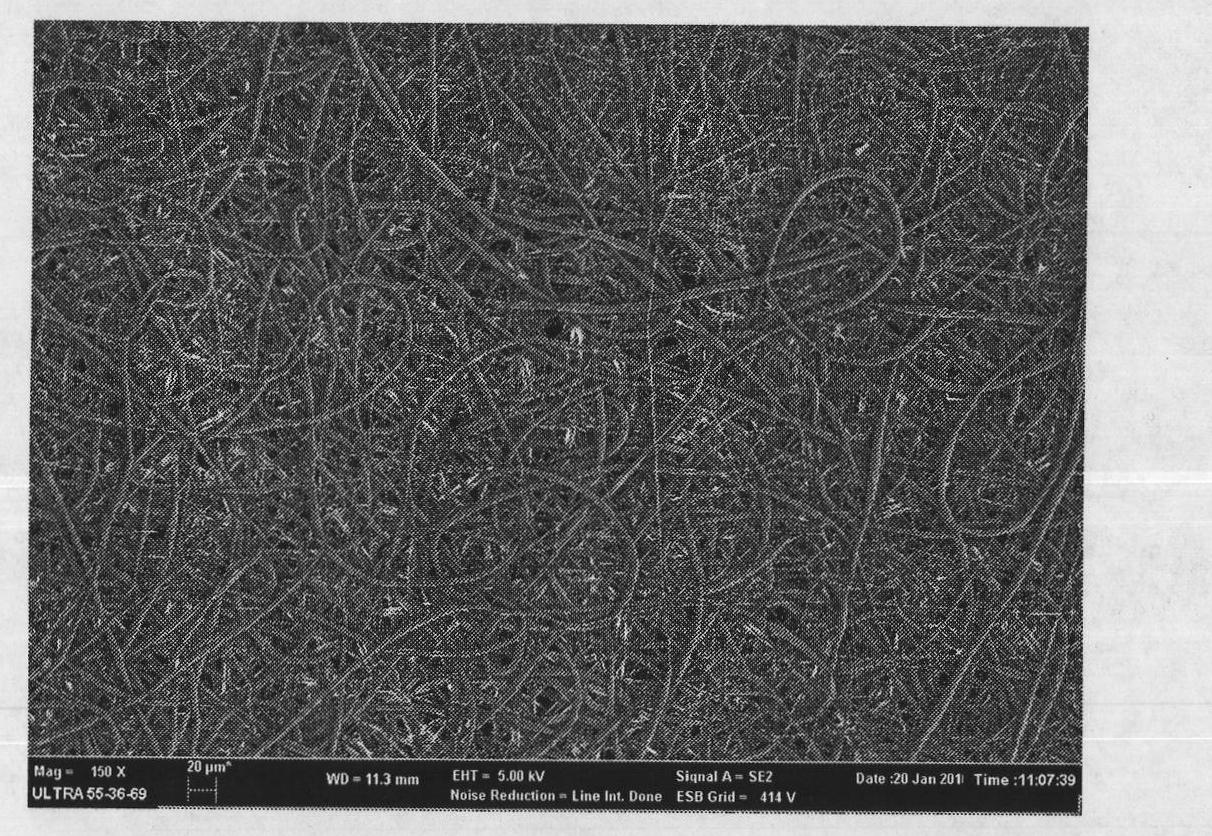

[0048] Using PLGA as a raw material, it was dissolved in chloroform to prepare a solution with a concentration of 20% (wt). Add this mixture solution to the electrospinning syringe controlled by the syringe pump, set the voltage of the high-voltage generator to 20KV, and the collection distance to 20cm, a film composed of ultrafine fibers with nanometer-scale diameters can be obtained randomly, and then the The film was washed several times with deionized water and dried in vacuum before use. The film is first immersed in a solution of polyethyleneimine (PEI, 1-3 mg / ml) for 5-10 minutes, and then washed with deionized water with pH=7.0. Then BMP-2 and PDGF are made into a solution with a concentration of 0.1-10 μg / ml, and the film is soaked in the solution for 10-30 minutes for adsorption, and then washed with deionized water with pH=7.0. Then immerse in polyallylamine (PAH, 3mg / ml) and polyacrylic acid (PAA, 3mg / ml) solution in turn, cycle 3-4 times, all use deionized water ...

Embodiment 3

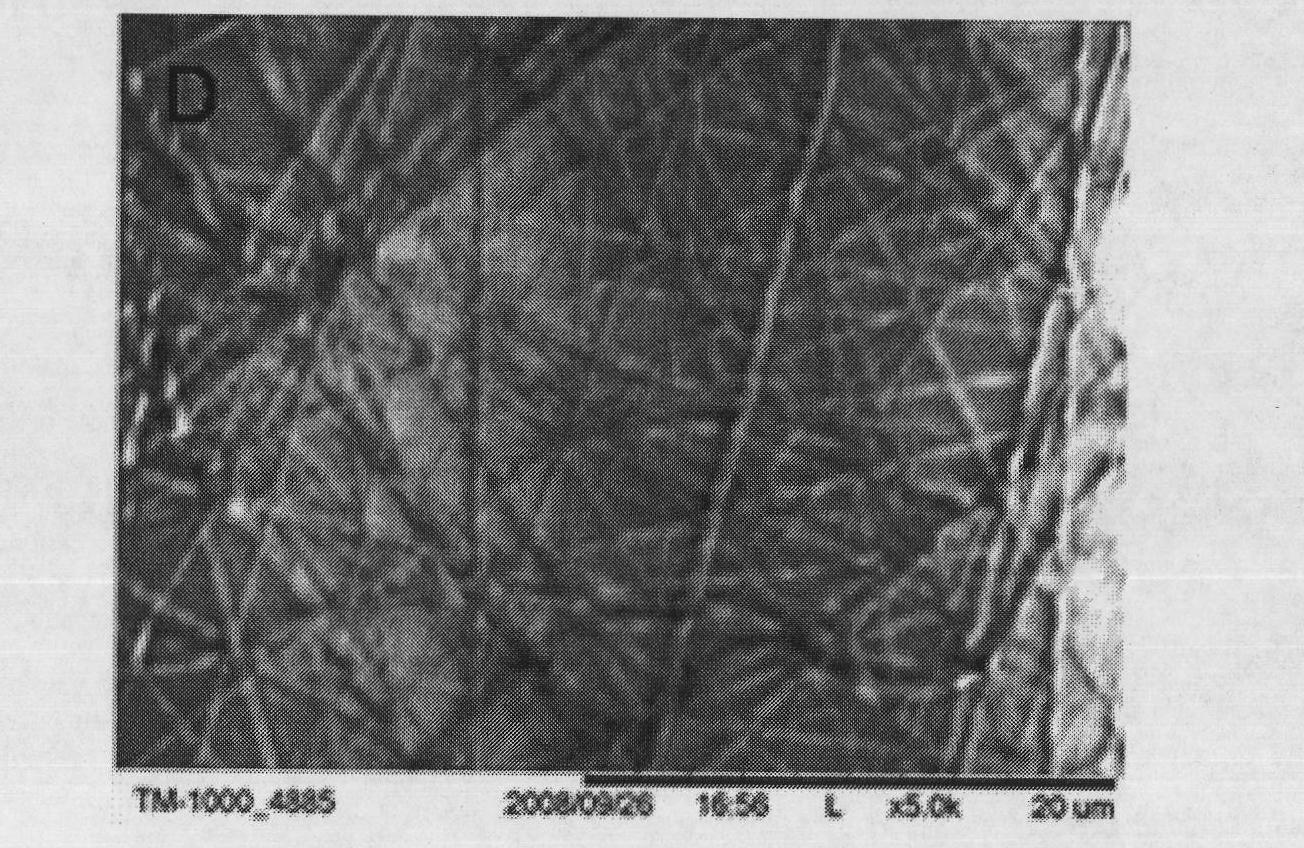

[0051] PLGA and collagen (collagen) were used as raw materials (2:1), dissolved in hexafluoropropanol to prepare a solution with a concentration of 10% (wt). Add this mixture solution to the electrospinning syringe controlled by the syringe pump, set the voltage of the high-voltage generator to 15KV, and the collection distance to 15cm, and a film composed of ultrafine fibers with nanometer-scale diameters can be obtained randomly, and then the The film was washed several times with deionized water and dried in vacuum before use. Prepare BMP-2 and PDGF into a solution with a concentration of 0.1-10 μg / ml, soak the film in the solution for 10-30 minutes for adsorption, and then wash with deionized water with pH=7.0. Then immerse in polyallylamine (PAH, 3mg / ml) and polyacrylic acid (PAA, 3mg / ml) solution in turn, cycle 3-4 times, all use deionized water to elute after each deposition. Next, a P38 inhibitor (SB203580) and an ERK inhibitor (PD98059) were dissolved in dimethyl sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com