Process and system for ammonia spraying flue gas desulfurization and sulfur dioxide recovery

A sulfur dioxide recovery system technology, applied in the field of flue gas purification, can solve the problems of low mass transfer efficiency of separation equipment, high operating costs, serious secondary pollution, etc., achieve low cost, increase production capacity, and avoid secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

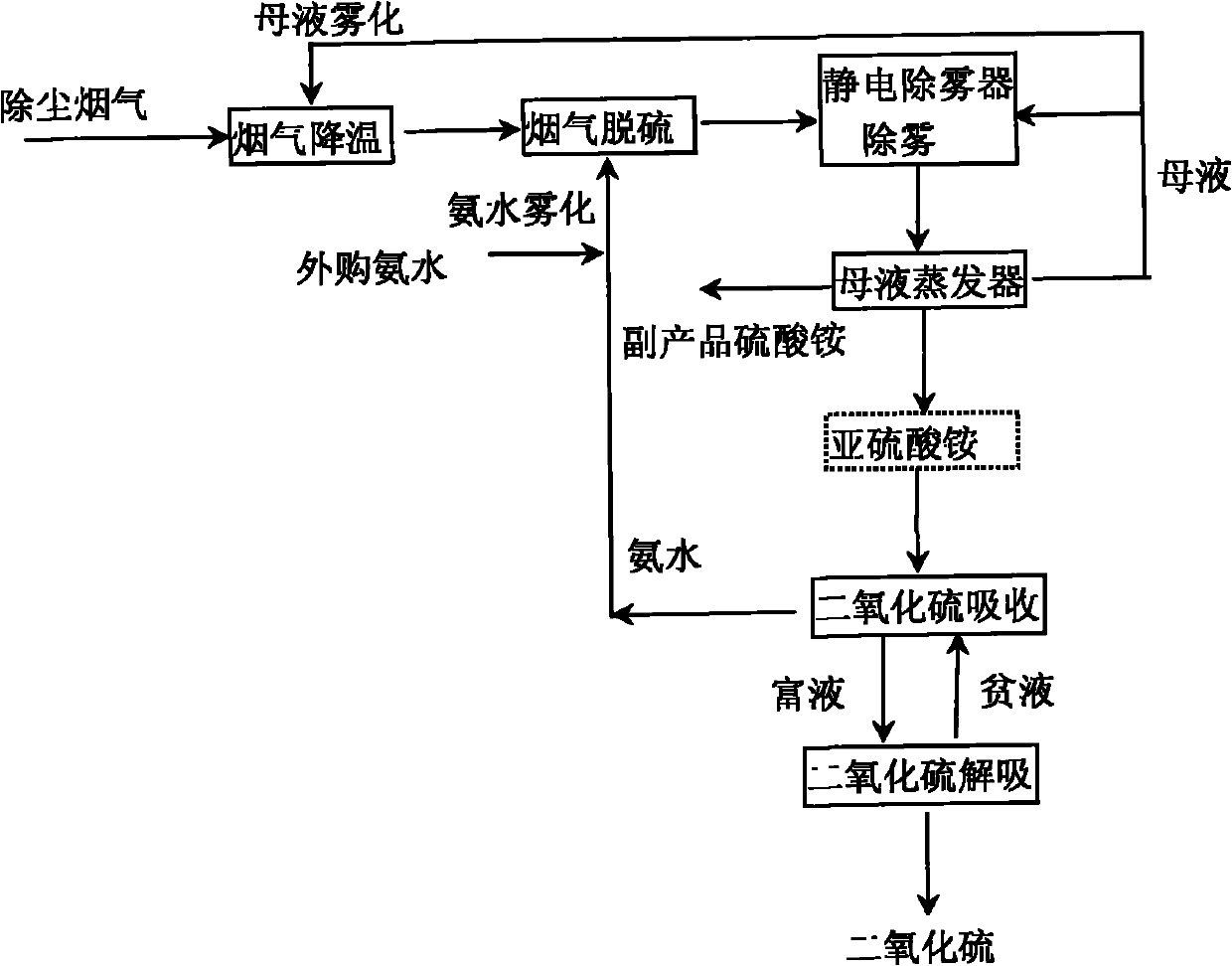

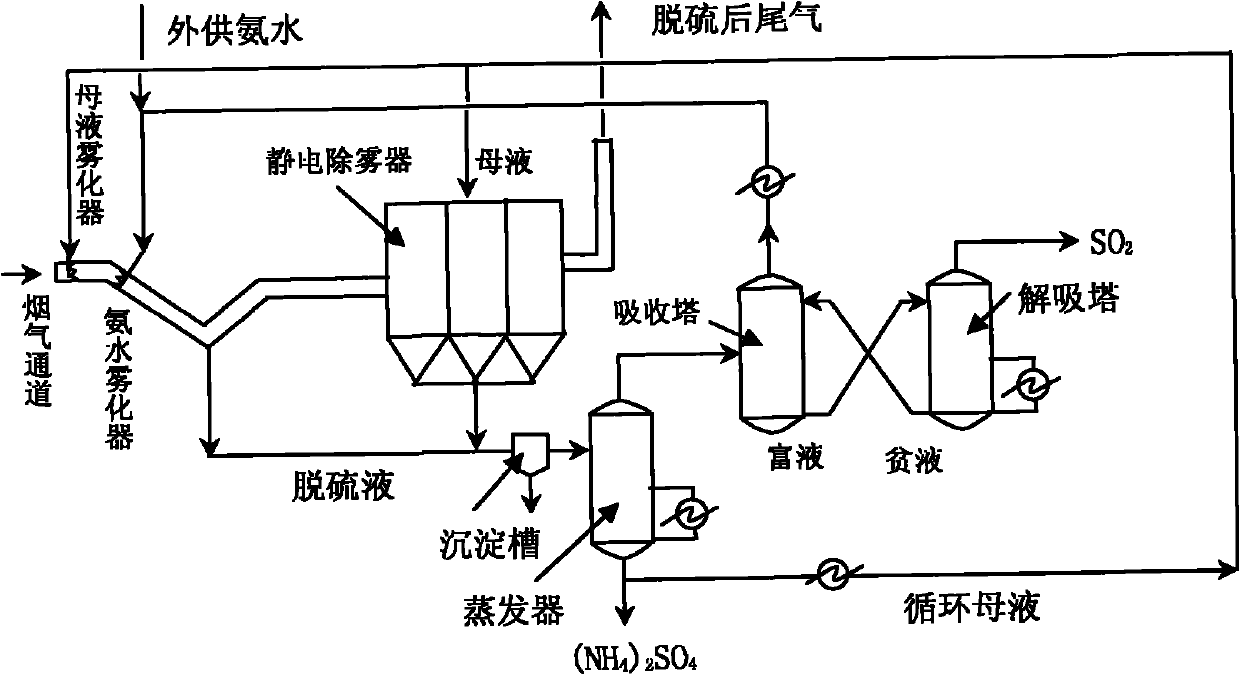

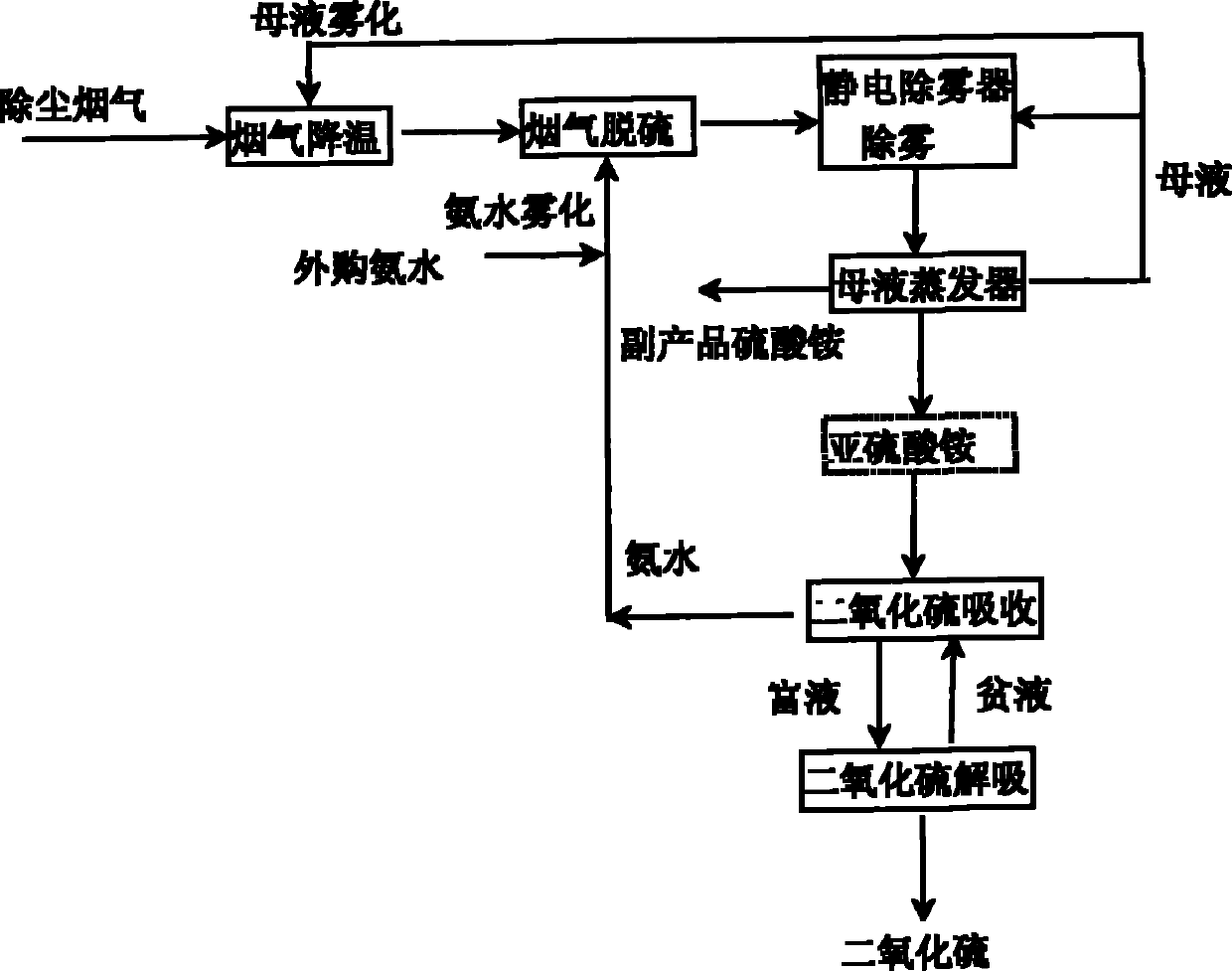

[0041] figure 1 The process flow of the ammonia spray flue gas desulfurization and sulfur dioxide recovery process of the present invention is given, and the ammonia spray flue gas desulfurization and sulfur dioxide recovery process of the present invention will be described in detail below using the desulfurization process for sintering machine tail gas in the iron and steel industry.

[0042] The temperature of the burnt tail gas (flue gas) after dust removal by the dust collector is about 130°C, and the wind speed in the flue gas pipeline is about 15m / s. The circulating mother liquid is atomized by a high-pressure pump (atomizing atomizer) and mixed with the exhaust gas in the flue gas pipeline, and the temperature of the flue gas is dropped sharply to about 45°C, the flue gas becomes saturated wet flue gas, and the diameter of the atomized mother liquid is 10μm-30μm. Ammonia water is atomized by another high-pressure pump (ammonia sprayer), and the diameter of the atomize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com