Preparation method of composite premix feed and obtained composite premix feed

A premixed feed and mixture technology, applied in animal feed, animal feed, application, etc., can solve the problems of low cost, high cost, cumbersome process, etc., and achieve the effect of high chelation rate, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

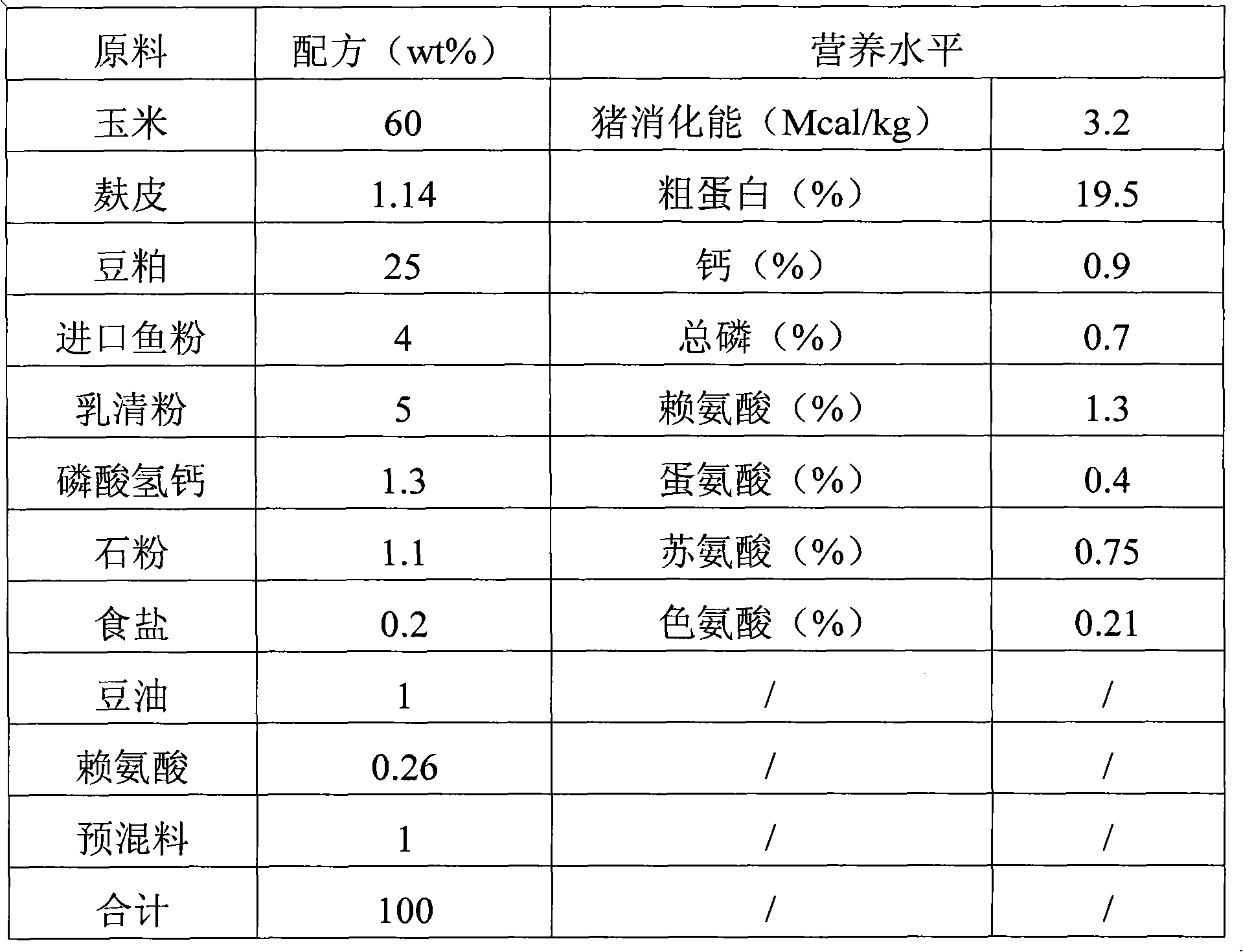

Embodiment 1

[0020] Mix 1kg of biochemical fulvic acid, 1kg of zinc sulfate, and water with an amount of 30% of the total mass of raw materials added, and pile up at room temperature for 7 days, then heat the obtained mixture to 100°C for 1 hour, and then vacuum and depressurize Dried and packaged to obtain the finished product.

Embodiment 2

[0022] Mix 2 kg of sodium humate (conventional commercially available humic acid, black), 1 kg of a mixture of zinc sulfate and ferrous sulfate with a mass ratio of 1:1, and water with an amount of 50% of the total mass of raw materials added, and stack at room temperature After 10 days, the obtained mixture was placed in a vacuum tank and heated to 105° C. for 1 hour, then dried under reduced pressure in vacuum, and packaged to obtain a finished product.

Embodiment 3

[0024] Mix 2 kg of fulvic acid, 1 kg of ferrous sulfate, and water whose water volume accounts for 40% of the total mass of raw materials added, and pile up at room temperature for 9 days, then heat the obtained mixture to 60°C and keep it for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com